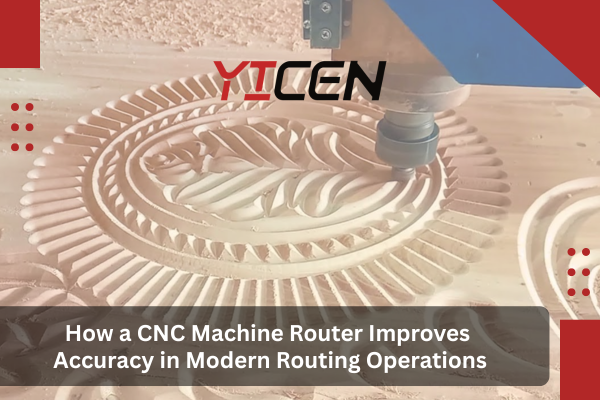

Manufacturing shops everywhere are discovering what CNC machine router technology can do for their operations. These computer-controlled machines have changed the game for woodworkers, sign makers, and fabricators who need consistent, accurate results without manual routing headaches.

Think about hand-routing a complex design versus letting a CNC machine router handle it. The trim router might wobble, measurements could be off, and repeating the same cut becomes nearly impossible. This technology eliminates problems while streamline operations and reducing waste.

What Is a CNC Machine Router?

A CNC machine router works by following digital instructions to move cutting tools exactly where needed. The setup includes stepper motors for movement control, linear rail systems for smooth travel, and design software that turns CAD drawings into actual cuts. The gantry frame holds everything steady while carving, engraving, and routing happen automatically.

Machines move along three axes – the z-axis goes up and down, while x-axis and y-axis movements handle horizontal patterns. The cutting area varies between models, with some handling small projects and others accommodating sheets of plywood measuring 4×8 feet.

Safety becomes crucial with these powerful machines. Operators need safety eyewear with side shields, hearing protection, and dust masks since cutting creates debris. A shop vacuum system helps manage mess, and emergency stops should always be within reach.

CNC Router vs. CNC Milling Machine: Understanding the Differences

People often confuse CNC routing with milling machine operations, but they’re built for different jobs. The choice depends on what materials get processed and how precise work needs to be.

| Feature | CNC Machine Router | Milling Machine |

| Materials | Wood, MDF, plastic, aluminum | Steel, titanium, hard metals |

| Accuracy | ±0.003″ to ±0.015″ | ±0.0005″ to ±0.003″ |

| Speed | 10,000-30,000 RPM | 100-8,000 RPM |

| Focus | Speed over power | Power over speed |

CNC machine router shines when speed matters more than ultra-tight tolerances. Industrial CNC operations run these machines for cabinet doors and signage where superior precision isn’t the main goal – getting consistent, good-quality parts quickly is. Industrial CNC machines are designed for throughput over micron-level accuracy.

A cnc milling machine takes the opposite approach. These heavier, more rigid machines prioritize accuracy above everything else, making them perfect for metal parts requiring precise fits.

How CNC Machine Routers Improve Precision and Efficiency?

Superior Precision with CNC Router Machines

Modern CNC machine router designs achieve impressive accuracy through smart engineering choices. Linear rail guidance keeps everything moving smoothly, while feedback systems constantly check position accuracy. Quality machines hold tolerances around 0.002 inches across their work area.

The machine that’s built for precision includes features most people never see. Ball screws eliminate play in the drive system, carbide cutting tools stay sharper longer, and temperature compensation prevents thermal expansion from affecting dimensions. The CNC machine router xe-pro and similar models use these technologies to compete with light milling operations, delivering highly precise results that are repeatable across production runs.

Efficiency in Cutting Materials

Getting the most from these machines means understanding how materials behave. Parameters need adjustment based on hardwood, MDF, plastic, or metals. Smart operators optimize tool paths to minimize waste and maximize speed.

| Material | Feed Rate | Speed | Depth |

| MDF | 120-180 IPM | 18,000-24,000 RPM | 0.125″ |

| Hardwood | 80-120 IPM | 15,000-20,000 RPM | 0.075″ |

| Aluminum | 40-80 IPM | 12,000-18,000 RPM | 0.030″ |

Dust collection systems really help improve the quality of the cut and make the machine last longer. A good dust shoe sends suction to where the cutting happens, which keeps chips from getting in the way and stops buildup from messing up the accuracy. Controlling dust properly also makes the tools last much longer.

Increased Productivity with Automation

Real efficiency gains come from automation features keeping machines running with minimal supervision. Tool changers swap bits automatically, while systems can load and unload workpieces without intervention.

Smart workspace layouts let operators prepare the next job while current ones run. Customer support teams help optimize workflows, finding improvements that pay for equipment faster than expected. Many shops use the machine more efficiently after technical assistance consultations.

The Flexibility of CNC Machine Routers in Industrial and Hobbyist Settings

CNC Routing for Large Projects

Industrial CNC installations feature massive work areas – some exceed 60×120 inches for architectural work. These systems use hybrid table designs combining vacuum workholding with traditional clamps.

Quality control gets built into processes through measurement systems checking dimensions during cutting. The foxalien cnc machine router and other similar industrial tools have strong parts made to work non-stop without stopping. Reinforced gantry designs prevent flex under loads, while industrial stepper motors deliver consistent power throughout production runs.

Affordable Solutions for Hobbyists

Entry-level machines have made CNC technology accessible to small shops and schools. The masuter pro represents this category well – user-friendly controls, straightforward setup, and ease of use without sacrificing capability. These prove professional results don’t require industrial budgets at a lower price point.

Operators new to cnc often worry about learning curves, but modern machines include intuitive software and documentation. The masuter 3s bridges hobbyist and professional capabilities while maintaining affordability. Easy-to-install mounting systems and comprehensive support team assistance help newcomers get productive quickly. Many manufacturers now offer easy-to-use interfaces that reduce setup time.

The Importance of CNC Machine Router Add-ons for Improved Functionality

Add-ons for Enhanced Cutting Power

CNC machine router platforms accept various upgrades expanding capabilities beyond basic cutting. A 40w laser attachment transforms machines into precision engraving systems, perfect for detailed artwork or product marking. These add-on systems maintain accuracy as primary operations.

Rotary attachments open cylindrical machining possibilities – furniture legs, architectural columns, decorative turnings. The rotary axis maintains precision standards while providing unlimited rotation, making complex geometries achievable.

Higher-power spindle upgrades increase cutting speeds in demanding materials while reducing heat buildup. Variable torque characteristics across speed ranges optimize performance based on material requirements.

Improved Compatibility with a Range of Materials

Modern machines handle far more than wood projects. With proper tooling and parameter settings, the machine offers reliable performance across diverse material types. Understanding material characteristics and cutting principles makes the difference between success and frustration.

Carbide tooling provides longer tool life and better surface finishes compared to standard steel bits. Special coatings reduce friction and heat generation – particularly important with plastic materials that melt under wrong conditions. Advanced controllers automatically adjust parameters, reducing setup time and preventing mistakes. Compatibility extends to cut a wide range of substrates when operators understand fundamentals.

Workholding Solutions and Workbench Setup for Maximum Precision

Getting parts to stay put during cutting affects both accuracy and safety. Vacuum tables provide even clamping pressure across large, flat workpieces without introducing distortion forces. These work particularly well with sheet goods and thin materials that might bend.

The workbench foundation matters more than most realize. Vibration transmission through flimsy bases shows up in surface finish and dimensional accuracy. Proper leveling ensures consistent z axis positioning, while good workholding fixtures maintain part position throughout machining sequences. Quality setups usually have systems that help place parts exactly where they need to be for complicated builds.

Even small workpiece movement during cutting creates dimensional errors or surface defects. Precision cutting demands careful attention to how parts get positioned and secured. CNC machine router’s performance depends heavily on proper workpiece restraint systems. Routers offer excellent capabilities when workholding gets done right, but rigidity throughout the system remains essential. Wide range of materials require different clamping strategies for optimal results.

Conclusion: CNC Router Machines for Every Need

CNC machine router technology keeps improving, offering shops unprecedented speed, accuracy, and versatility combinations. The machine that’s right depends on material requirements, production volumes, and accuracy needs. Success comes from matching capabilities to applications while maintaining proper safety practices.

FAQs About CNC Machine Router

Q1: What precision should I expect from a CNC machine router?

Quality systems hold ±0.005″ tolerances reliably, with better models achieving ±0.002″ when properly maintained. Environmental factors affect these numbers. High-end models such as the Makita RT0701C, which come with a spindle, provide accurate and reliable results every time.

Q2: Can these machines cut metals effectively?

Absolutely – aluminum, brass, and similar soft metals work well. Steel requires specialized tooling, slower speeds, and sometimes cooling systems.

Q3: How do I maintain CNC machine router accuracy over time?

Regular calibration checks, proper linear rail lubrication, monitoring spindle runout, and replacing worn components help maintain precision. Following manufacturer maintenance schedules prevents most accuracy problems.

Q4: Are CNC machine router systems beginner-friendly?

Modern machines include user-friendly software and safety features helping newcomers get started. However, understanding basic machining principles and safety procedures remains essential before operating equipment.