Introduction

Walking into any modern manufacturing facility today, you’ll likely encounter two very different types of machines, both claiming to be “3D printers.” The confusion between Impresión 3D vs desktop 3D printing has led countless businesses down expensive rabbit holes and hobbyists toward unrealistic expectations.

What surprised everyone is that the basic differences between desktop 3D printing and industrial 3D printing go much further than just size or cost. The global market reached $29.94 billion in 2025 and is expected to grow to $66.42 billion by 2030 (Mordor Intelligence, 2025), yet many people still don’t know when to use each type of technology.

What is 3D Printing?

When aerospace engineers at Boeing discuss additive manufacturing, they mean industrial-grade systems that differ vastly from consumer alternatives. The distinction between 3D printing and desktop 3D printing becomes crucial when lives depend on component reliability. Boeing currently uses more than 60,000 printed parts on their airplanes, according to Harvard Business Review from 2018. SpaceX also makes rocket engine parts from a special metal called Inconel using a method called Sinterización directa de metales por láser, as mentioned in a study by Joshi and Sheikh from 2015.

Industrial system capabilities:

- Advanced materiales: Titanium alloys that cost $200 per kilogram and PEEK polymers that can handle temperatures up to 300 degrees Celsius.

- Precision technologies: Selective Laser Melting building parts atom by atom, Electron Beam Melting in vacuum chambers

- Critical applications: Flight components, medical implants, tooling surviving millions of cycles

Boeing’s Andy Pfeiffer revealed their Apache helicopter rotor system now takes nine hours to print versus a full year using traditional forging (WellPCB Case Studies, 2025). This exemplifies why understanding 3D printing and desktop 3D printing differences matters for manufacturers.

What is Desktop 3D Printing?

The comparison between 3D printing and desktop 3D printing reveals two completely different philosophies. Desktop systems democratize manufacturing for education, prototyping, and creative projects (3DGence Industrial Report, 2023).

Walk into engineering classrooms and you’ll find students exploring 3D printing applications during lunch breaks. Small businesses create custom solutions overnight instead of waiting weeks for traditional manufacturing.

Desktop system reality:

- Accessible materials: PLA costing $25 per spool, ABS for mechanical needs

- User-friendly technologies: Fused Deposition Modeling, entry-level Stereolithography

- Practical applications: Prototyping, education, custom solutions

- Honest precision: 100-200 microns for most projects (Omni3D Technical Documentation, 2020)

Graham Faulknor, who’s tested over 50 machines, notes the capabilities between 3D printing and desktop 3D printing have narrowed for prototyping, though industrial precision remains unmatched for critical applications (TechRadar, 2025).

Comparison of Materials: 3D Printing vs Desktop 3D Printing

The material capabilities represent the most significant dividing line between these technologies:

| Aspecto | Industrial 3D Printing | Desktop 3D Printing |

| Materiales | Titanium, stainless steel, Inconel, PEEK | PLA, ABS, PETG, basic resins |

| Operating Temperature | Up to 1,800°C chamber heating | Ambient to 260°C hotend |

| Part Strength | Aerospace/medical grade | Prototype/hobby grade |

| Cost per kg | $50-500+ | $20-80 |

Industrial systems like the Nexa3D XiP Pro can process high-temperature materials and achieve production throughput that’s “about 10x” faster than previous generation equipment, according to Glen Mason from DeMarini Sports.

Materials Used in 3D Printing and Desktop 3D Printing

The material divide between 3D printing and desktop 3D printing tells everything about their intended purposes. Aerospace companies like Boeing partner with Norsk Titanium for 787 Dreamliner components surviving decades of flight stress (Protolabs, 2023).

Meanwhile, SpaceX prints rocket engine chambers from Inconel withstanding temperatures hot enough to melt copper. This showcases the material capabilities gap between 3D printing and desktop 3D printing applications.

Desktop systems work with fundamentally different materials—PLA melting at just 180°C works perfectly for prototyping but nowhere near aerospace requirements. The beauty lies in accessibility: anyone can explore 3D printing and desktop 3D printing without exotic materials or specialized training.

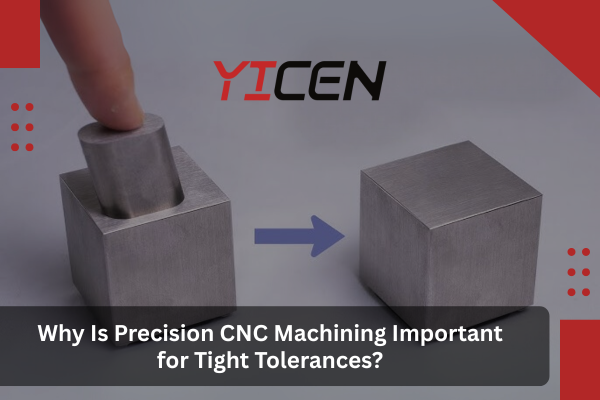

Accuracy and Precision: Which is More Accurate?

Precision needs show the big difference between regular 3D printing and desktop 3D printing. In the recent SpaceX-33 mission by NASA, they sent printed medical tools that had very tight measurements, down to tens of microns. That level of accuracy can’t be achieved with typical home 3D printers (VoxelMatters, 2025).

Industrial systems from EPlus3D routinely achieve 20-micron layer resolution with repeatable results across thousands of parts (EPlus3D, 2023). This consistency explains why aerospace manufacturers choose industrial over consumer alternatives.

Erik Palitsch learned this firsthand at SpaceX before founding Freeform, a startup raising $14 million from Boeing and Nvidia. Their closed-loop systems monitor prints “on a microsecond scale”—technology demonstrating the precision gap between 3D printing and desktop 3D printing (TechCrunch, 2024).

Applications in Real Life: Where to Use Which?

Understanding applications helps clarify when to choose between 3D printing and desktop 3D printing solutions.

Industrial applications: Boeing transformed their 787 manifold from three machined parts into one printed component. Airbus manufactures titanium door locking shafts for A350 aircraft using powder bed fusion (WellPCB Case Studies, 2025). These applications require certified materials and documentation that consumer systems cannot provide.

Desktop applications: Teachers worldwide use desktop systems, bringing engineering concepts to life. Product designers create functional prototypes in hours instead of weeks, demonstrating practical applications for 3D printing in different scenarios.

Oliver Braun used a Formlabs Form 2, creating SpaceX Falcon 9 models so detailed that SpaceX employees were impressed (Additive-X, 2022). Cost? Under $50 in materials versus thousands for traditional model making.

Conclusión

The comparison between 3D printing vs desktop 3D printing reveals two sides of the same revolutionary technology serving fundamentally different purposes. While desktop systems democratize access to additive manufacturing for education and prototyping, industrial systems enable mission-critical component production for aerospace, medical, and automotive applications.

The divide between 3D printing vs desktop 3D printing isn’t disappearing—it’s becoming more pronounced as both technologies mature. Industrial systems push toward higher temperatures and tighter tolerances, while desktop systems focus on ease of use and affordability.

Both technologies will continue growing, but success depends on matching the right tool to specific applications and performance requirements. The worst mistakes happen when people expect desktop capabilities from industrial budgets or industrial performance from desktop investments.

Preguntas frecuentes

Q1: What is the primary difference between 3D printing vs desktop 3D printing?

Industrial systems produce certified, end-use parts with advanced materials and validated processes. Desktop systems excel at prototyping, education, and custom solutions using consumer-grade materials.

Q2: Can someone use both desktop 3D printing vs 3D printing professionally?

Absolutely. Many professionals leverage both technologies—desktop systems for rapid prototyping and concept validation and industrial systems for final production parts requiring certification.

Q3: How should businesses choose between 3D printing vs desktop 3D printing?

Start by thinking about what you need. If you require approved parts, special materials, or high-precision work like in aerospace, go with industrial systems. But if you’re looking for fast prototyping, learning resources, or tailored solutions, desktop systems are easier to use and more accessible.