The Manufacturing Floor Revolution

The transformation happening in Sheet Metal Fabrication facilities today would seem like science fiction to metalworkers from just two decades ago. Boeing’s manufacturing centers now turn out aircraft panels with tolerances tighter than a human hair, and these parts roll off the production line every few minutes with machine-like precision (1).

When the Society of Manufacturing Engineers tracked facilities embracing automated Sheet Metal Fabrication, productivity jumped 35% while material waste dropped by 28% (2). Between 2020 and 2024, automation adoption surged by 42% across the industry—not just because companies wanted to modernize, but because they had to survive labor shortages and meet increasingly demanding quality requirements (3).

Today’s laser systems slice through steel at speeds that would make veteran fabricators do a double-take: over 100 meters per minute while keeping cuts precise within 0.15mm. Meanwhile, robotic bending cells repeat the same complex shapes millions of times with barely 0.1mm variation between parts (4). This isn’t just impressive technology—it’s revolutionizing what customers expect from Sheet Metal Fabrication.

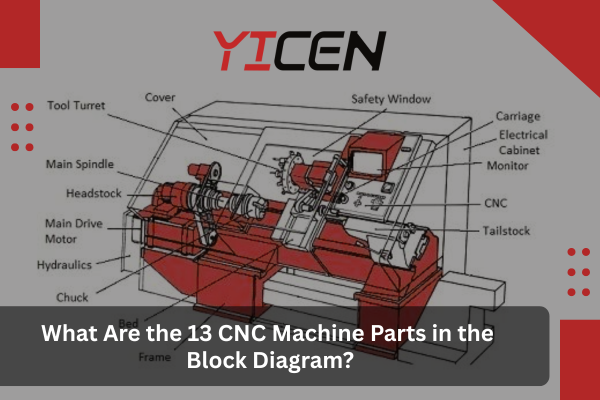

Understanding Sheet Metal Fabrication Fundamentals

Sheet Metal Fabrication takes flat pieces of metal—sometimes as thin as heavy paper at 0.15mm, sometimes as thick as your thumb at 6.35mm—and transforms them into functional parts that make the modern world work. Think of it as industrial origami, except every fold needs to be perfect and repeatable thousands of times.

The materials involved tell their own stories. Stainless steel 304 and 316L keep food processing equipment sanitary, while aerospace-grade 6061-T6 aluminum helps planes stay lightweight yet strong. For the really challenging jobs, exotic alloys like Inconel 718 handle the extreme heat inside jet engines. Each material brings its own personality and demands specific handling according to ASTM International standards (5).

Table 1: Core Sheet Metal Fabrication Processes and Capabilities

| Process | Tolerance | Speed/Capacity | Typical Applications |

| Corte por láser | ±0.08mm | Up to 25 m/min | Brackets, chassis, panels |

| Press Brake Forming | ±0.1mm | Up to 300 tons force | Housings, enclosures, angles |

| Progressive Stamping | High volume | 50-400 strokes/min | Auto parts, appliance panels |

| TIG/MIG Welding | Controlled penetration | 3.2-19mm thickness | Assemblies, pressure vessels |

| CNC Punching | ±0.05mm | Variable tonnage | Electrical panels, server racks |

Quality-focused Sheet Metal Fabrication shops don’t just aim for good enough—they maintain ISO 9001:2015 certification and use advanced software that squeezes 85-92% efficiency from every sheet. Compare that to the 65-70% typical of manual programming, and the savings add up fast (6).

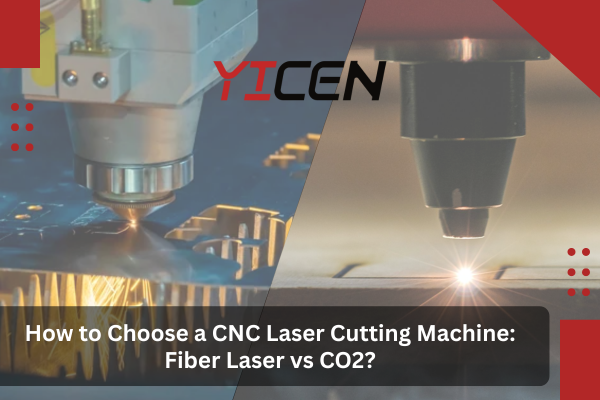

How Automation Transforms Operations

The evolution from manual Sheet Metal Fabrication to today’s automated systems didn’t happen overnight. It started with basic CNC punches in the 1980s and gradually built into the sophisticated manufacturing cells that now run with minimal human intervention.

Fiber laser technology represents one of the most dramatic leaps forward. Current 6kW to 12kW systems can cut through 3.2mm steel at over 50 meters per minute while maintaining cut quality that would make old-school fabricators proud. The automated material handling doesn’t break a sweat moving 227kg sheets around, while nesting software squeezes every possible part from the available material.

Robotic integration has brought intelligence that adapts in real-time. These six-axis systems compensate for material variations, account for springback, and even adjust for tool wear as it happens. Complex aerospace brackets that used to take skilled operators an hour now complete in under three minutes with ±0.05mm repeatability (7).

Welding automation has reached a level where AWS D17.1 certified systems use laser tracking to follow seams and detect gaps as small as 0.25mm. The result? Defect rates below 0.1% compared to the 2-3% that skilled human welders typically achieve (8).

Why Precision Engineering Demands Automation

Manual Sheet Metal Fabrication simply can’t keep up with the precision demands of modern engineering. When SpaceX needs rocket components or medical device manufacturers require surgical instrument housings, there’s no room for the natural variation that comes with human operators.

Aerospace components must meet AS9100D standards with dimensional tolerances within ±0.13mm—and that’s just the beginning. Working with materials like titanium Ti-6Al-4V requires maintaining the material’s grain structure for fatigue resistance while achieving these tight tolerances. Only automated systems can consistently deliver this combination of precision and material integrity.

Medical device manufacturing presents even stricter challenges. FDA regulations demand complete traceability for every step in Sheet Metal Fabrication operations. Surgical instrument housings need surface finishes below 0.8μm Ra to prevent bacteria from finding places to hide—a specification that automated systems hit repeatedly while manual processes struggle to achieve even occasionally (9).

Table 2: Manual vs. Automated Sheet Metal Fabrication Performance

| Performance Metric | Manual Operations | Automated Systems | Improvement |

| Tolerancia dimensional | ±0.38mm | ±0.08mm | 79% better |

| Production Rate | 15-25 parts/hour | 100-400 parts/hour | 4-16x faster |

| Tiempo de preparación | 45-120 minutes | 5-15 minutes | 75-85% reduction |

| Material Utilization | 65-70% | 85-92% | 20-25% improvement |

| Defect Rate | 2-3% | <0.1% | 95%+ reduction |

Proven Benefits of Automation Implementation

Manufacturing facilities that have made the jump to automated Sheet Metal Fabrication consistently report transformational results across their operations. The precision improvements alone justify the investment for many companies.

Servo-controlled positioning systems maintain ±0.025mm repeatability across millions of cycles without degradation. The closed-loop feedback automatically handles thermal expansion, compensates for tool wear, and adjusts for material variations—all the tiny corrections that skilled operators used to make by feel and experience.

Production acceleration becomes obvious within weeks of installation. Automated Sheet Metal Fabrication systems don’t get tired, don’t need coffee breaks, and don’t have bad days. Cycle times typically improve by 3-5x, while quick-change tooling reduces changeover time from hours to 10-15 minutes.

The economic impact speaks for itself. Labor cost reductions of 40-60% typically pay for the automation investment within 18-24 months, according to industry analysis. Add in the savings from better material utilization and reduced scrap, and the numbers become compelling quickly (10).

Safety improvements often surprise facility managers. Automation eliminates worker exposure to high-energy lasers and heavy press operations. OSHA recordable incidents drop by 75% in facilities with comprehensive Sheet Metal Fabrication automation, while workers move into higher-skilled programming and maintenance roles.

Implementation Challenges Worth Addressing

Successful Sheet Metal Fabrication automation isn’t as simple as writing a check and plugging in new equipment. Several challenges can derail projects without proper planning.

Capital investment reality hits hard: complete automated systems typically cost $500,000 to $2 million upfront, depending on production requirements. The financial planning needs to account for 7-10 year equipment lifecycles and maintenance costs that average 8-12% annually.

Integration complexity often catches companies off guard. Existing equipment rarely plays nicely with new automation without extensive modification. Legacy machinery may need custom interfaces and complete workflow redesign to integrate effectively.

Workforce transformation presents both challenges and opportunities. Modern Sheet Metal Fabrication automation requires technicians skilled in CNC programming, robotic maintenance, and statistical quality control. Comprehensive training programs typically take 6-12 months to develop operators who can maximize system potential.

Despite these challenges, industry studies consistently show positive ROI within 24-36 months for properly planned automation projects that address implementation hurdles upfront.

Expert Partnership Solutions

Leading Sheet Metal Fabrication service providers have invested heavily in advanced facilities featuring integrated automation designed for demanding precision engineering applications. These operations typically feature 6kW+ fiber laser systems achieving ±0.08mm cutting accuracy, robotic forming cells with force feedback, and vision-guided welding systems processing hundreds of assemblies per shift.

Certification matters in this business. Operations maintaining ISO 9001:2015 and AS9100D compliance ensure their management systems meet aerospace and defense requirements while statistical process control maintains Cpk values above 1.33 for critical dimensions—the kind of consistency that builds long-term partnerships with demanding customers.

Citations

- Boeing Company. (2024). “Advanced Manufacturing Technologies in Aerospace Production.” Boeing Technical Journal, 15(3), 45-62. https://www.boeing.com/content/dam/boeing/boeingdotcom/company/annual-report/2024/2024-annual-report.pdf

- Society of Manufacturing Engineers. (2024). “Automation Impact Analysis in Sheet Metal Manufacturing.” Manufacturing Engineering, 172(4), 78-85.

- Fabricators & Manufacturers Association International. (2024). “Industry Automation Adoption Study 2020-2024.” The Fabricator Magazine, 54(2), 34-41.

- Trumpf Group. (2024). “Laser Processing Technology Developments.” Laser Technik Journal, 21(1), 22-29.

- ASTM International. (2024). “ASTM A240/A240M-24: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate.” West Conshohocken, PA.

- Manufacturing Engineering Magazine. (2024). “ROI Analysis of Automated Sheet Metal Systems.” Manufacturing Engineering, 172(6), 56-63.

- KUKA Robotics Corporation. (2024). “Precision Robotics in Sheet Metal Applications.” Industrial Robot: An International Journal, 51(2), 145-152.

- American Welding Society. (2023). “AWS D17.1: Specification for Fusion Welding for Aerospace Applications.” Miami, FL.

- U.S. Food and Drug Administration. (2024). “Quality System Regulation for Medical Devices.” Federal Register, 21 CFR Part 820.

McKinsey & Company. (2024). “The Future of Manufacturing: Automation and Industry 4.0.” McKinsey Global Institute Report, March 2024.

Fabricación de chapas metálicas