What are Optical Lens Components?

Optical lens components are precision-engineered mechanical parts that support, protect, align, and control optical elements within imaging and display systems. In consumer electronics, these components include lens barrels, retaining rings, focusing mechanisms, mounting brackets, protective housings, aperture assemblies, and alignment fixtures. They are integral to smartphones, tablets, digital cameras, webcams, augmented reality devices, virtual reality headsets, projectors, and scanning equipment. The primary function of optical lens components is maintaining precise optical alignment, protecting delicate glass elements, enabling focus adjustment, and ensuring consistent image quality. Their dimensional accuracy and surface quality directly impact optical performance, making them critical to device functionality and user satisfaction in photography, videography, and display applications.

B. Principales requisitos técnicos

Manufacturing optical lens components requires extreme precision and meticulous attention to detail. Tolerances for critical dimensions typically range from ±0.0005″ to ±0.0002″ for mounting surfaces and alignment features, with concentricity tolerances often held to 0.0003″ TIR to prevent optical axis deviation. Material specifications must provide dimensional stability across temperature ranges, low thermal expansion coefficients, and compatibility with optical coatings and adhesives.

Surface finish requirements are exceptionally stringent, with Ra values frequently below 16 microinches for sealing surfaces and optical interfaces. Thread specifications for focusing mechanisms demand precise pitch control and smooth operation through thousands of adjustment cycles. Components must maintain geometric accuracy including flatness within 0.0001″ for critical mounting surfaces and perpendicularity within 0.0005″ for optical axis alignment.

Environmental considerations include resistance to temperature fluctuations that could affect focus positioning, protection against moisture and dust ingress, and compatibility with optical cements and protective coatings. Mechanical stability under vibration and impact is essential, particularly for mobile devices and drone-mounted cameras.

C. Retos y soluciones de fabricación

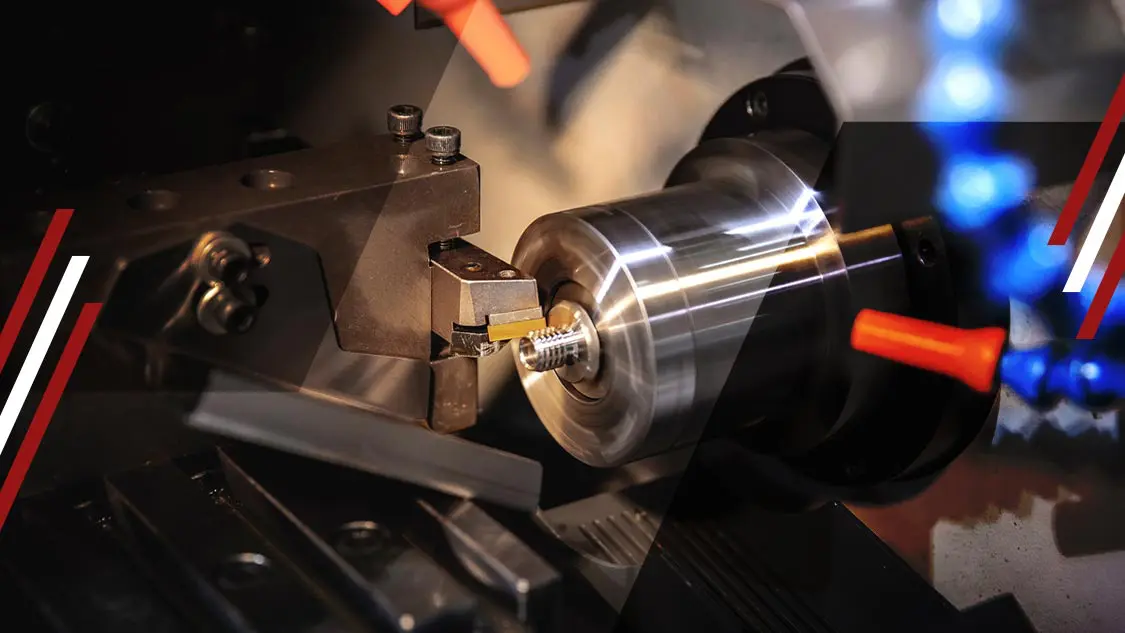

Machining optical lens components presents formidable challenges including achieving mirror-finish surfaces on complex geometries, maintaining concentricity across multiple diameters, and producing ultra-precise threads for focusing mechanisms. The combination of tight tolerances with thin-walled structures creates risk of distortion during machining. Material properties like brass’s tendency to produce built-up edge or aluminum’s susceptibility to surface imperfections require specialized cutting strategies.

Yicen Precision addresses these challenges through diamond-turning capabilities that produce optical-quality surface finishes directly from machining operations, eliminating secondary grinding processes. Our 5-axis CNC machining centers perform complete operations in single setups, ensuring perfect concentricity between internal and external diameters while maintaining geometric relationships critical for optical alignment.

We utilize custom-designed precision mandrels and expanding collets that support thin-walled components without inducing stress or deformation. Advanced CAM programming optimizes cutting parameters for each material, controlling chip formation and minimizing surface defects. Climate-controlled machining environments maintain stable temperatures, preventing thermal expansion that could compromise dimensional accuracy.

Quality control includes comprehensive CMM inspection with optical probing for critical features, laser scanning for complex profiles, and interferometric measurement of flatness on optical mounting surfaces. Surface finish verification employs contact and non-contact profilometry to ensure specifications are met. Optical alignment testing validates concentricity and perpendicularity of assembled components.

D. Aplicaciones y casos de uso

Precision-machined optical lens components enable superior imaging across diverse consumer electronics applications:

- Smartphone and Tablet Camera Modules: Lens barrels, mounting rings, and focus actuator housings for multi-camera systems and advanced imaging capabilities

- Digital Cameras and Camcorders: Interchangeable lens mounts, zoom mechanism housings, and image stabilization component assemblies

- Laptop and Desktop Webcams: Compact lens assemblies, protective bezels, and mounting brackets for video conferencing equipment

- Virtual and Augmented Reality Headsets: Precision lens holders, adjustable focus mechanisms, and optical alignment fixtures for immersive displays

- Drone and Action Cameras: Lightweight lens housings, gimbal mounting components, and protective covers for aerial and sports imaging

- Projector Optical Systems: Lens positioning assemblies, adjustment mechanisms, and thermal management components for display projection

- Barcode Scanners and Optical Sensors: Focusing lens assemblies, protective windows, and alignment components for industrial and retail scanning devices

E. Why Choose Yicen Precision for Optical Lens Components?

Yicen Precision stands as your premier partner for optical lens components CNC machining through our specialized expertise in precision optics manufacturing. Our rapid prototyping services deliver sample parts within days, enabling quick design validation and iterative refinement before committing to production tooling. We offer seamless scalability from limited prototype runs through high-volume manufacturing, maintaining optical-grade precision regardless of order quantity.

Our engineering team provides expert DFM consultation specifically tailored to optical applications, optimizing designs for manufacturing efficiency while preserving critical optical performance parameters. We ensure complete material traceability with certified mill test reports and detailed documentation supporting quality audits and compliance requirements.

Our cost-effective approach leverages efficient machining strategies, optimized tool paths, and material utilization planning that reduces waste without compromising the exceptional precision and surface quality your optical lens components demand. With dedicated project management, transparent communication, and commitment to delivery schedules, we become your trusted manufacturing partner for bringing innovative optical products to market.