A. What are Hydraulic and Pneumatic Components?

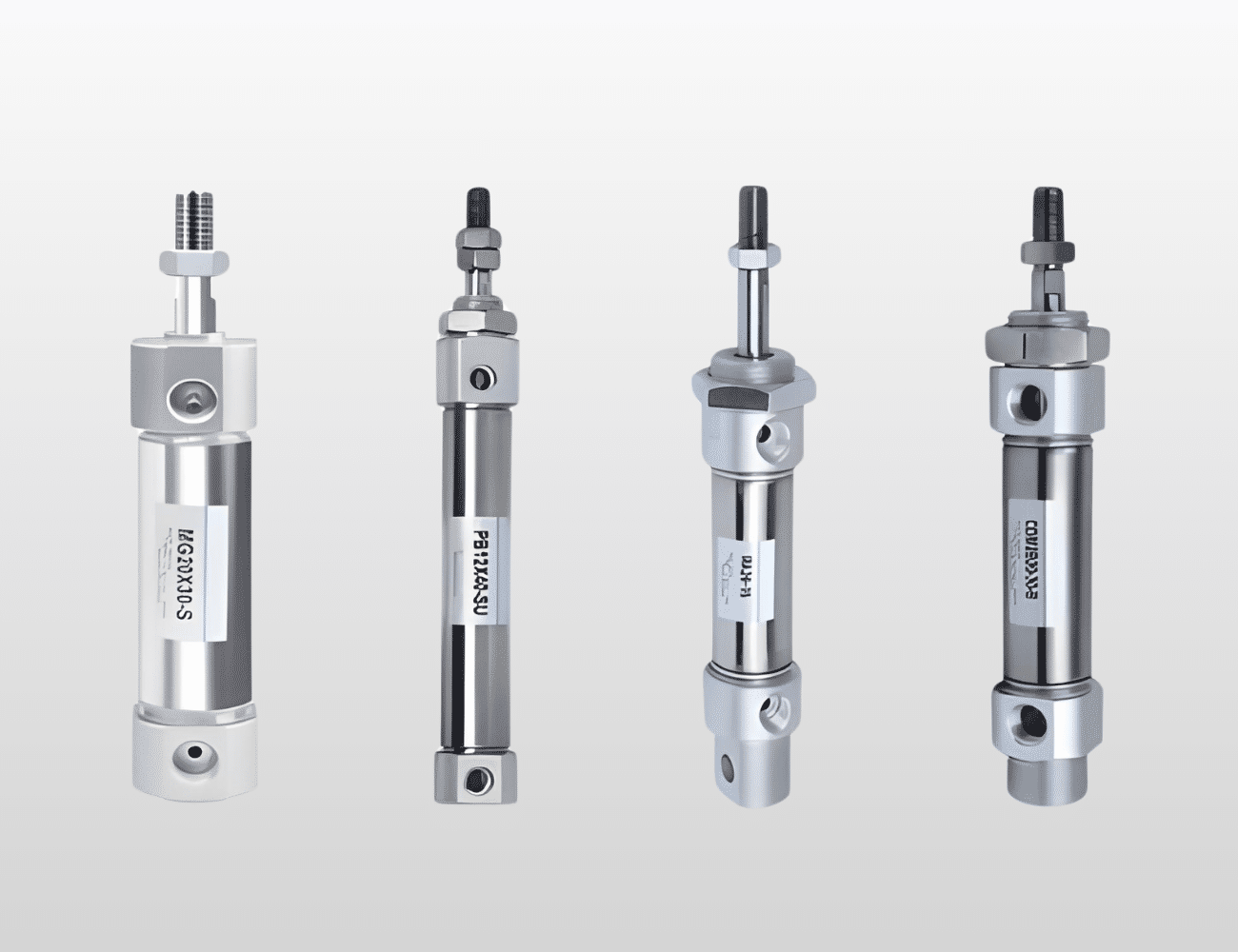

Hydraulic and pneumatic components are specialized mechanical assemblies that control, direct, and regulate fluid power systems in industrial machinery. These include hydraulic manifold blocks, cylinder barrels, piston rods, valve bodies, pneumatic actuator housings, air distribution blocks, and specialized fittings with complex internal porting. They are utilized across manufacturing automation, mobile equipment, material handling systems, injection molding machines, and industrial robotics. Their essential function is to convert fluid pressure into mechanical force, control flow direction and volume, and maintain system pressure integrity while operating under demanding conditions including high pressures (up to 10,000 PSI for hydraulics), rapid cycling, and contaminated environments.

B. Principales requisitos técnicos

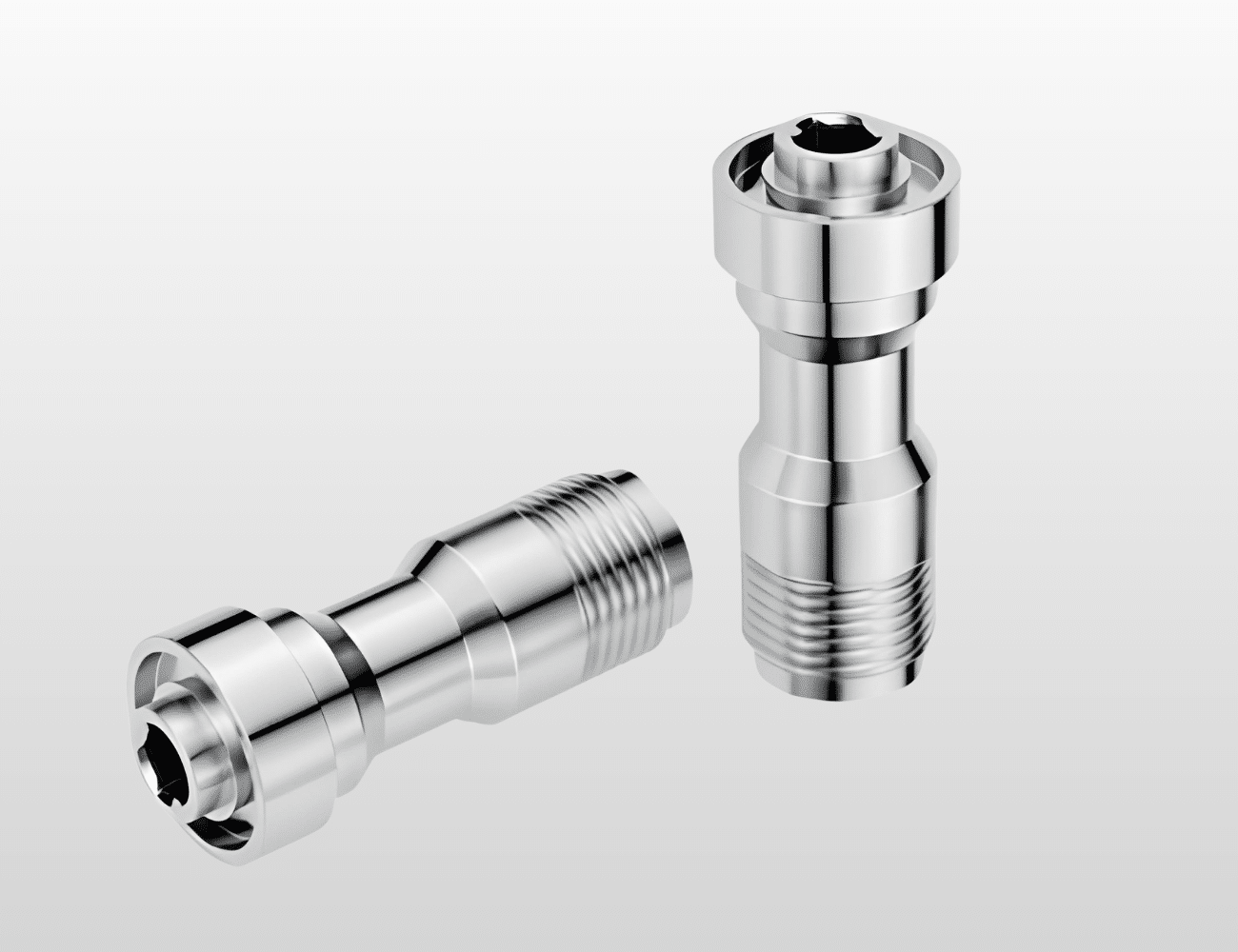

Precision hydraulic and pneumatic components require extremely tight tolerances, typically ±0.0002″ to ±0.0005″ for sealing surfaces, bore diameters, and mating interfaces to prevent fluid leakage and ensure proper component fit. Material specifications demand corrosion-resistant alloys such as aluminum 6061-T6 and 7075-T6, 303 and 316 stainless steel, naval brass, and specialized tool steels depending on pressure ratings and fluid compatibility. Surface finish is critical with requirements ranging from 8-16 Ra for cylinder bores to 32-63 Ra for external surfaces and port connections.

These components must withstand continuous hydraulic pressures from 1,500 to 5,000 PSI (industrial applications) or pneumatic pressures from 80 to 250 PSI without deformation, porosity, or seal failure. Internal passage geometry requires precise cross-drilling intersections with deburred edges to prevent turbulence and contamination generation. Temperature resistance spans from -20°F to 250°F for hydraulic systems and -40°F to 200°F for pneumatic assemblies. Environmental resistance includes compatibility with various hydraulic oils, synthetic fluids, compressed air moisture, and chemical exposure while maintaining dimensional stability and surface integrity.

C. Retos y soluciones de fabricación

Machining hydraulic and pneumatic components presents unique challenges including cross-drilled internal passages with multiple intersecting holes requiring precise angular alignment and depth control. Deep-hole boring for cylinder barrels demands specialized tooling to maintain straightness and surface finish across extended lengths. Thin-walled manifold sections are susceptible to deflection and chatter during machining operations. Port intersections create burrs that can contaminate fluid systems if not properly deburred. Thread accuracy for high-pressure fittings requires precision tapping with proper engagement length.

Yicen Precision addresses these challenges through dedicated deep-hole drilling and boring equipment capable of producing cylinder bores up to 24″ deep with straightness within 0.001″ per foot. We utilize gun drilling and BTA drilling technologies for small-diameter deep holes with superior surface finishes. Our 5-axis CNC machining centers enable compound-angle drilling for complex manifold port configurations with positional accuracy of ±0.0005″. Advanced fixturing systems provide rigid workholding that minimizes deflection on thin-walled components.

For critical intersecting passages, we employ specialized deburring tools and electrochemical deburring processes to eliminate edge conditions without dimensional compromise. Every hydraulic and pneumatic component undergoes comprehensive CMM inspection of all critical dimensions, surface profilometry for bore finishes, and hydrostatic pressure testing up to 1.5x operating pressure to verify leak-proof integrity before shipment.

D. Aplicaciones y casos de uso

Industrial machinery hydraulic and pneumatic components manufactured by Yicen Precision serve critical applications:

- Injection Molding Machinery – Hydraulic clamping systems and ejector actuators

- Metal Forming Equipment – Press cylinders, die cushions, and slide positioning systems

- Automated Assembly Lines – Pneumatic pick-and-place actuators and gripper cylinders

- Sistemas de manipulación de materiales – Hydraulic lift tables, conveyor positioning, and gate controls

- Prensas industriales – Main ram cylinders, pressure intensifiers, and valve manifolds

- Máquinas herramienta CNC – Hydraulic clamping systems and pneumatic tool changers

- Packaging Equipment – Pneumatic actuators for filling, sealing, and labeling operations

- Testing Equipment – Precision hydraulic load frames and pneumatic control systems

E. Why Choose Yicen Precision for Hydraulic and Pneumatic Components?

Yicen Precision brings specialized expertise in manufacturing leak-free hydraulic and pneumatic components with guaranteed pressure integrity and dimensional precision. Our rapid prototyping services enable functional testing of custom manifold designs within days, allowing design validation before committing to production tooling. We provide comprehensive engineering collaboration including flow analysis, pressure drop calculations, and DFM recommendations to optimize component performance and reduce manufacturing costs.

Our quality management system ensures complete material traceability with mill certifications, dimensional inspection reports, and pressure test documentation for every component. We maintain strategic relationships with premium material suppliers ensuring consistent quality and competitive pricing for both standard and specialty alloys. Our production flexibility accommodates orders from single prototype units to high-volume production runs exceeding 10,000 pieces annually with identical quality standards. With decades of fluid power manufacturing experience and investment in specialized equipment, we understand the critical nature of leak-proof performance and deliver hydraulic and pneumatic components that exceed industry expectations.

Request a technical consultation to discuss your hydraulic and pneumatic components CNC machining requirements.