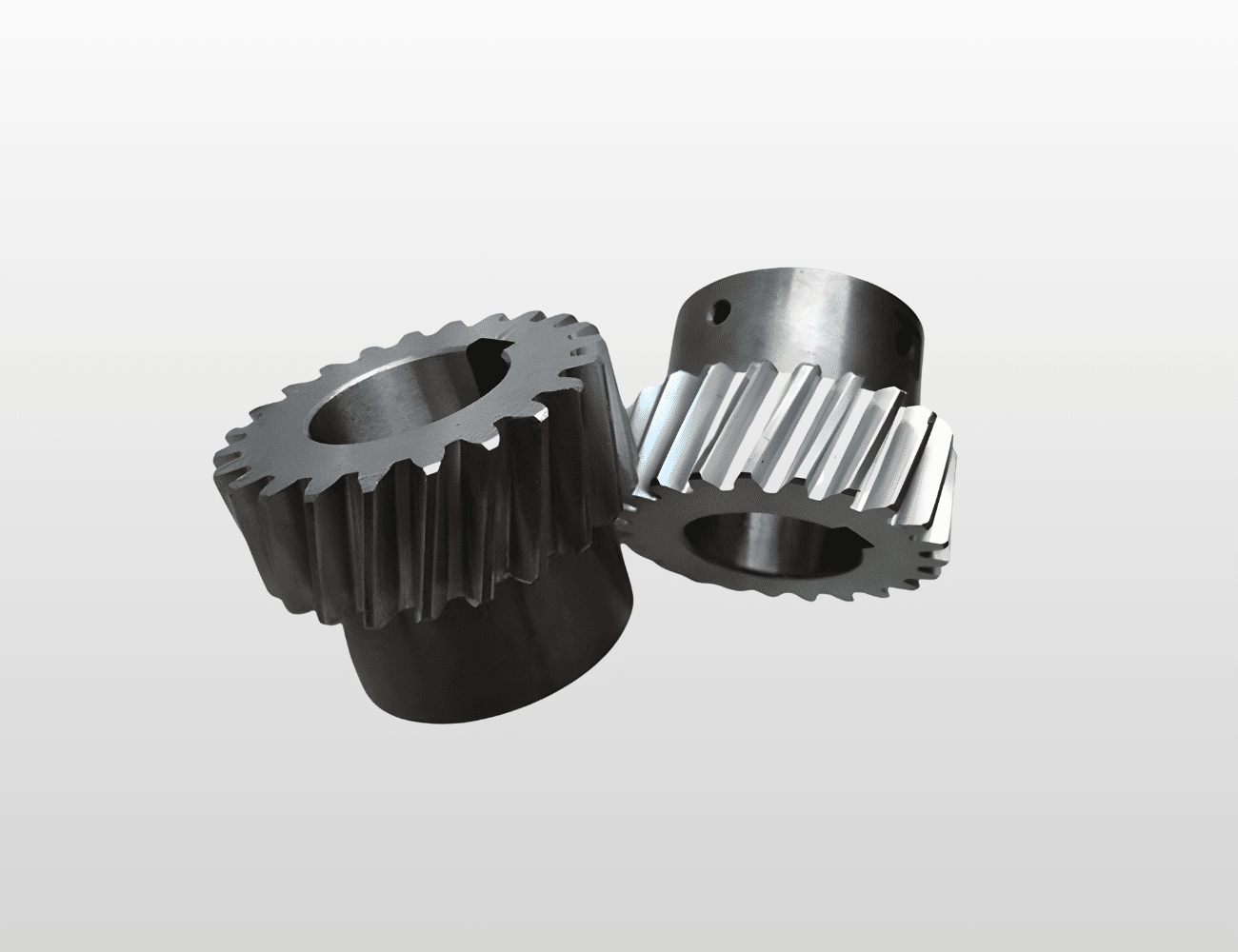

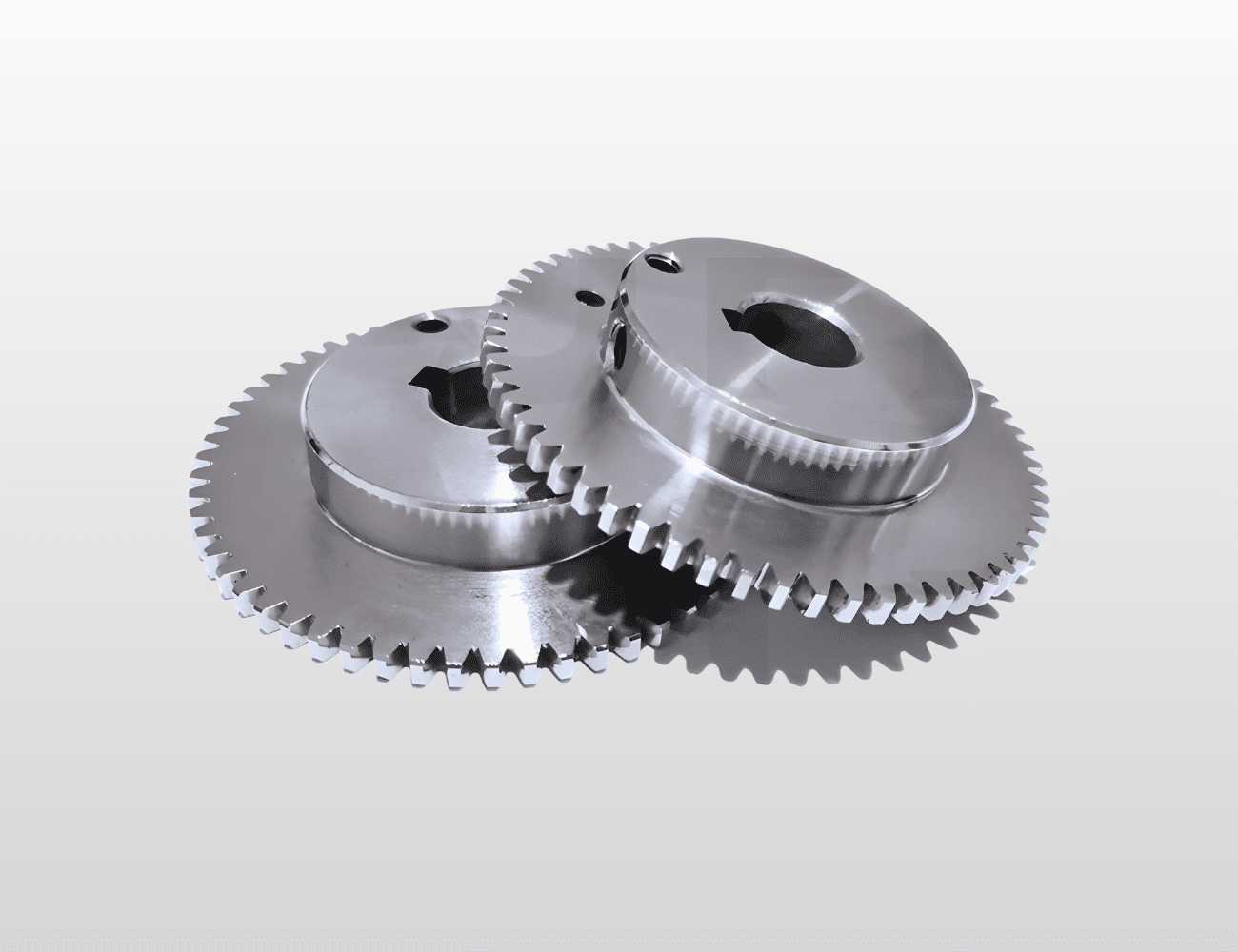

A. What are Actuators and Gears?

Actuators and gears are integrated mechanical systems that control robotic movement and force application. Actuators are devices that convert energy into motion, including linear actuators, rotary actuators, servo actuators, and stepper motor assemblies with precision-machined housings, shafts, and mounting interfaces. Gears include spur gears, helical gears, bevel gears, worm gears, and planetary gear systems that modify speed, torque, and direction of motion. These components are essential in industrial robotic arms, surgical robots, automated manufacturing systems, UAVs, collaborative robots, exoskeletons, and precision positioning systems. The performance, efficiency, and accuracy of robotic operations depend directly on the precision machining quality of actuators and gears, which must maintain tight tolerances and smooth operation across millions of cycles.

B. Principales requisitos técnicos

Actuators and gears for robotics demand exceptional precision with tolerances of ±0.0002″ to ±0.0005″ on critical dimensions to ensure proper meshing, minimal backlash, and accurate motion control. Gear tooth profiles must conform to AGMA standards, typically Quality Class 9-12 for high-precision robotics applications. Material specifications require surface hardness of HRC 58-62 for gear teeth while maintaining core toughness to resist impact loads and cyclic stress. Surface finish requirements range from Ra 8 to Ra 4 microinches on tooth flanks and bearing surfaces to minimize friction losses and wear. Concentricity specifications typically demand TIR below 0.0003″ on shaft journals and gear bores. Actuator housings require precise alignment features and mounting interfaces with positional tolerances within ±0.001″. Components must withstand contact stresses exceeding 250,000 PSI while operating across temperature ranges from -40°F to 300°F depending on application.

C. Retos y soluciones de fabricación

Machining actuators and gears presents complex challenges including maintaining precise involute tooth geometry across multiple teeth, achieving consistent tooth spacing and profile accuracy, and preserving dimensional stability through heat treatment cycles. Thin-walled actuator housings are susceptible to machining deflection and distortion. Complex internal passages for wiring, lubrication channels, and sensor mounting require multi-axis accessibility. Material hardness in pre-hardened steels increases tool wear and thermal management requirements during cutting operations.

Yicen Precision overcomes these manufacturing challenges through integrated 5-axis CNC machining that enables complete actuator and gear production in minimal setups, maintaining datum consistency throughout fabrication. Our advanced CAM software optimizes tool paths for gear generation using specialized milling cutters and hobbing techniques to achieve precise involute profiles and proper tooth geometry. We utilize precision work-holding fixtures specifically designed for gear and actuator components, preventing deflection while supporting delicate features. CMM inspection with specialized gear measurement software verifies tooth profiles, pitch accuracy, lead angles, and spacing with documented traceability. Our quality control measures include first-article inspection, in-process verification at critical manufacturing stages, and final dimensional validation. Certified heat treatment processes with minimal distortion are followed by finish grinding operations on critical surfaces, ensuring every actuator and gear component meets exact specifications for optimal performance and longevity.

D. Aplicaciones y casos de uso

Actuators and gears are utilized across diverse robotic platforms:

- Industrial Robotic Arms: Servo actuators with harmonic drives and planetary gear reducers for six-axis motion control

- Surgical Robotics: Miniature actuators and precision gears for minimally invasive procedures requiring micron-level accuracy

- Collaborative Robots (Cobots): Torque-sensing actuators with integrated gear systems for safe human-robot collaboration

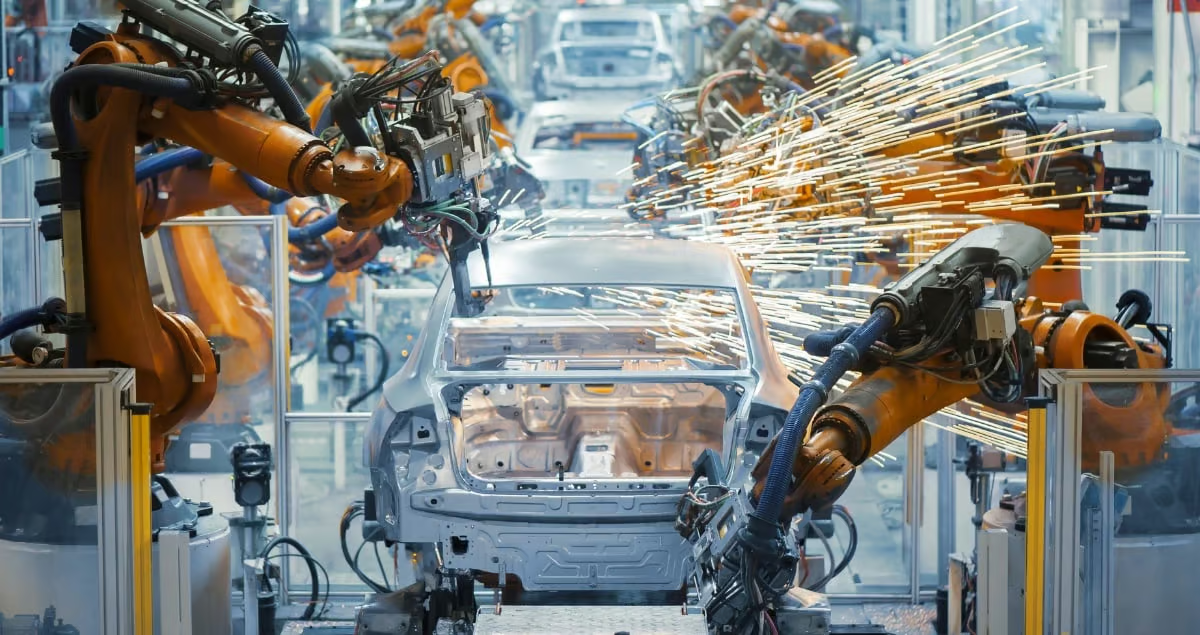

- Automated Manufacturing: High-speed actuators and gear trains for assembly lines, pick-and-place operations, and material handling

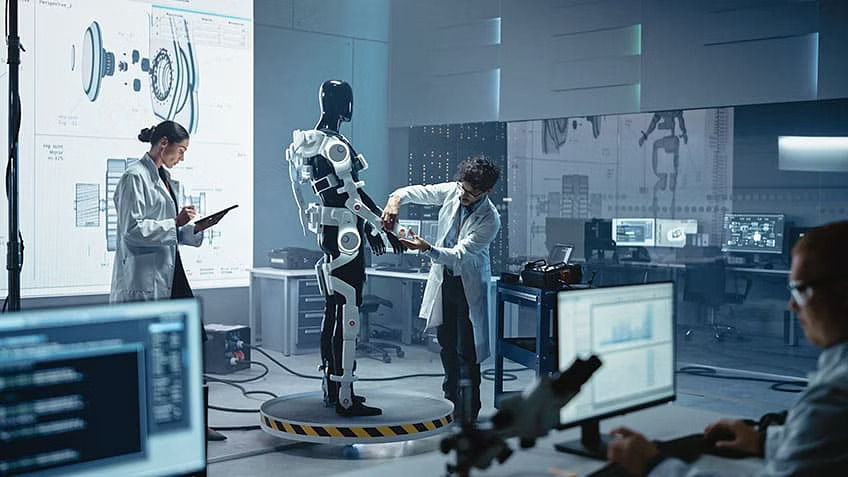

- Exoskeleton Systems: Lightweight actuators with high-ratio gear reducers for wearable robotic assistance devices

- Aerospace Robotics: Flight control actuators and precision gears for UAVs, drones, and satellite mechanisms

- Mobile Autonomous Robots: Differential drive actuators and steering gears for AGVs and warehouse automation

- Precision Positioning Systems: Linear actuators with lead screws and precision gear mechanisms for semiconductor manufacturing

E. Why Choose Yicen Precision for Actuators and Gears?

Yicen Precision delivers specialized expertise in manufacturing complex actuators and gears with rapid turnaround times from prototype development through full-scale production. Our engineering team provides comprehensive Design for Manufacturability (DFM) consultation, optimizing gear ratios, material selection, tooth geometry, and actuator housing designs for maximum performance and cost-efficiency. We maintain complete material traceability with certified mill test reports and heat treatment documentation for every component batch. Our scalable production capabilities accommodate both low-volume custom actuator designs and high-volume production runs with consistent quality throughout. State-of-the-art inspection equipment including gear analyzers, CMMs, and surface profilometers ensure dimensional accuracy and tooth profile conformance. Cost-effective solutions are achieved through optimized machining strategies, efficient material utilization, and strategic process planning that reduces manufacturing time without compromising quality. Contact us for a custom quote and technical consultation to discover how our precision actuators and gears can elevate your robotic system’s performance and reliability.