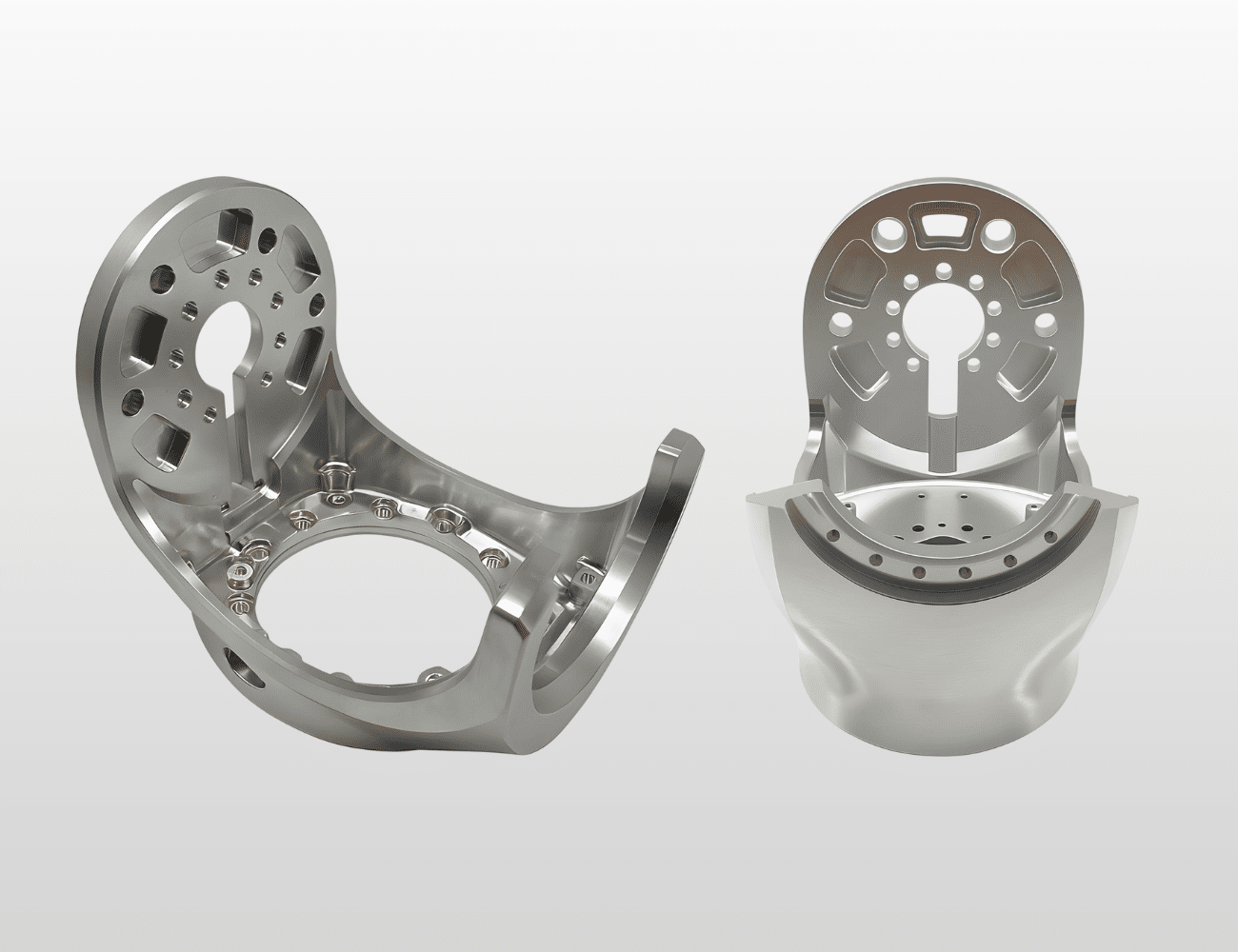

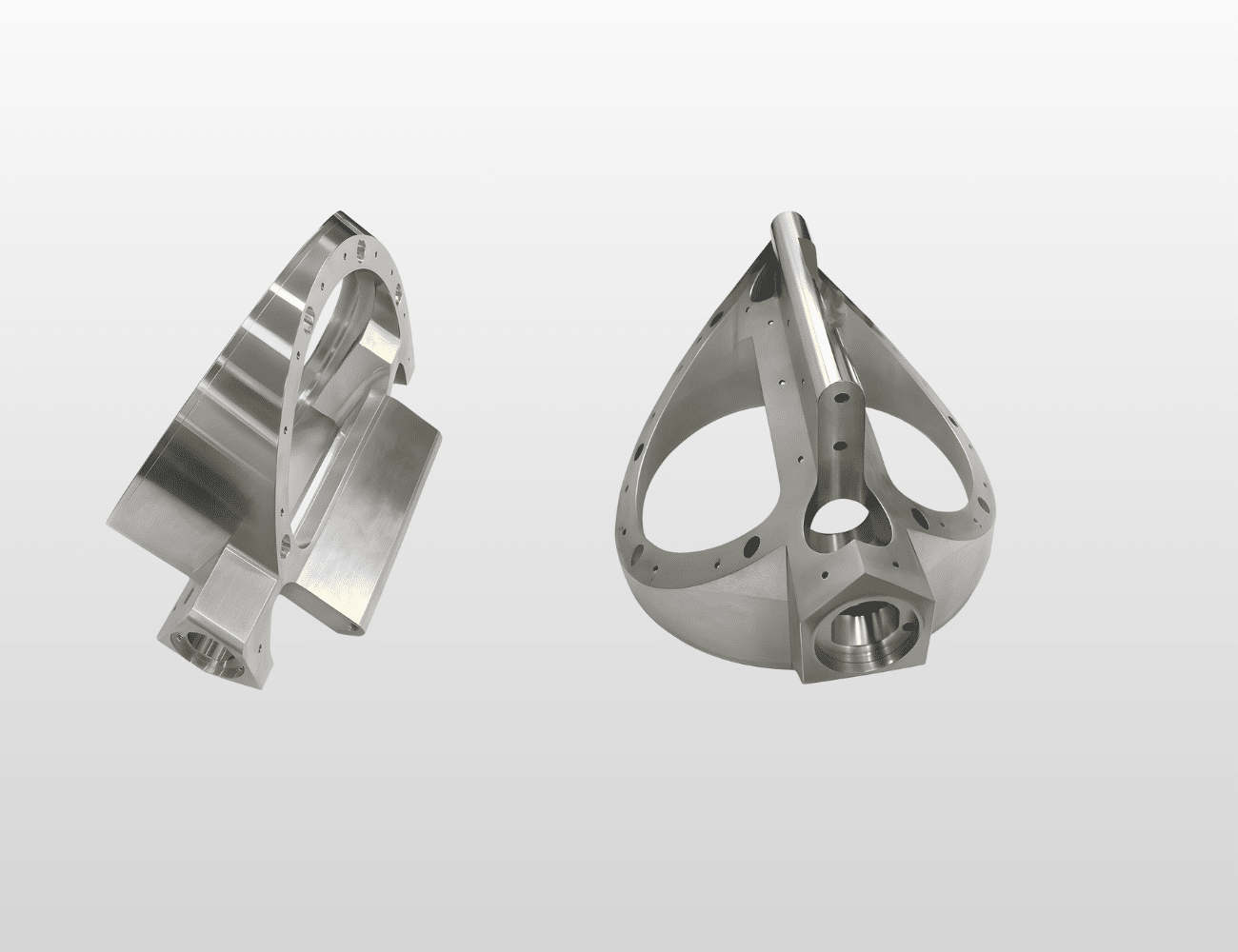

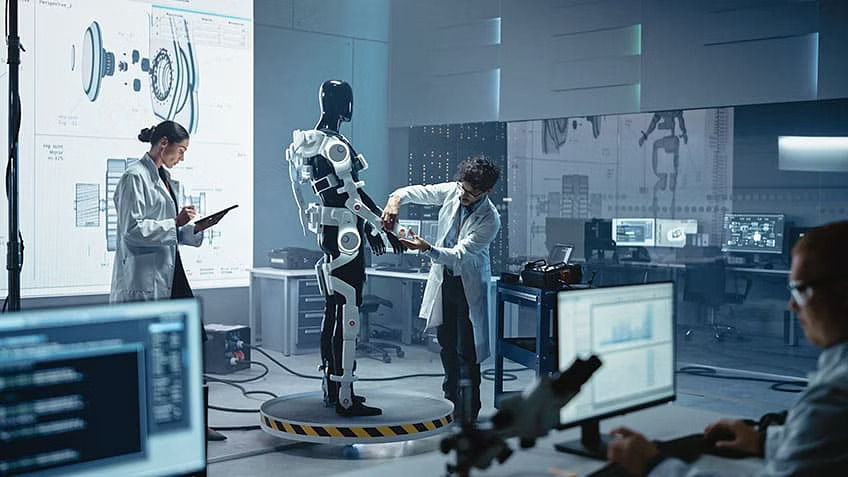

A. What are Custom Structural Frames?

Custom structural frames are precision-machined skeletal structures that form the primary load-bearing foundation of robotic systems. These include chassis assemblies, base plates, mounting platforms, support beams, gantry frames, and integrated structural enclosures designed specifically for robotic applications. They provide rigid mounting surfaces for motors, sensors, controllers, and mechanical components while maintaining dimensional stability throughout the robot’s operational envelope. Custom structural frames are essential in industrial robotic cells, autonomous mobile robots (AMRs), collaborative robot workstations, robotic welding systems, pick-and-place automation, and specialized robotics platforms. The precision and rigidity of these machined structures directly impact robot accuracy, repeatability, vibration dampening, and overall system performance across manufacturing, warehouse automation, medical robotics, and defense applications.

B. Principales requisitos técnicos

Custom structural frames for robotics demand exceptional dimensional accuracy with tolerances of ±0,001″ a ±0,003″. on critical mounting surfaces and alignment features to ensure proper component integration. Flatness specifications typically require 0.001″ per linear inch across large mounting surfaces to prevent stress and misalignment of installed components. Perpendicularity and parallelism between mounting faces must maintain tolerances within ±0.002″ to ensure accurate kinematic relationships. Material specifications must provide adequate stiffness while minimizing weight, with specific modulus ratios optimized for application requirements. Surface finish requirements range from Ra 63 to Ra 32 microinches on mounting interfaces to ensure proper component seating and gasket performance. Structural frames must withstand static and dynamic loads, vibration, thermal cycling, and environmental exposure without deformation. Hole positioning for fasteners and mounting features typically requires positional tolerances of ±0.005″ or better. Structural integrity must be maintained across operational temperature ranges from -40°F to 200°F depending on application environment.

C. Retos y soluciones de fabricación

Machining custom structural frames presents unique challenges including managing thermal growth and deflection in large workpieces, maintaining flatness across extensive surface areas, and achieving tight positional tolerances for numerous mounting holes and features. Complex pocket geometries for weight reduction require deep cavity machining with thin-wall considerations. Material removal in large aluminum frames can induce residual stress and distortion. Accessibility to all features in multi-sided frames demands sophisticated fixturing and setup strategies.

Yicen Precision addresses these manufacturing challenges through advanced 5-axis CNC machining that enables complete frame processing with minimal setups, reducing tolerance stack-up and improving feature relationships. Our CAM software optimizes cutting strategies to balance material removal rates while controlling heat generation and minimizing deflection during machining. We employ stress-relief processes and strategic machining sequences to manage residual stresses in aluminum and titanium frames. Precision fixtures and tombstone work-holding systems support large frames rigidly while providing multi-sided access. CMM inspection with large-envelope measurement capabilities verifies flatness, hole positions, and dimensional accuracy across entire frame assemblies with documented traceability. Our quality control measures include in-process verification, thermal stability monitoring, and final dimensional validation using laser tracker technology for large frames, ensuring every custom structural frame meets exact specifications for seamless integration and optimal robotic performance.

D. Aplicaciones y casos de uso

Custom structural frames are essential across diverse robotic applications:

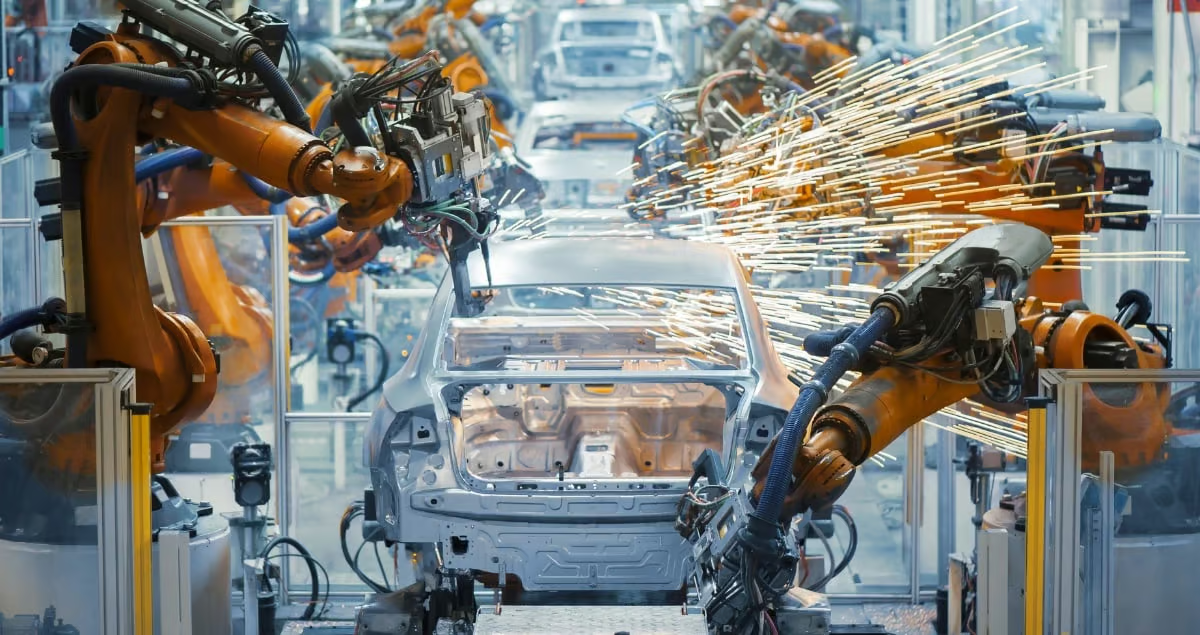

- Industrial Robotic Cells: Precision base frames and mounting platforms for multi-axis robots in manufacturing environments

- Autonomous Mobile Robots (AMRs): Lightweight chassis structures for warehouse logistics and material transport systems

- Collaborative Robot Workstations: Modular frame assemblies for flexible cobot deployment in assembly operations

- Gantry Robot Systems: Large-scale structural frames for Cartesian coordinate robots in material handling and machining

- Robotic Welding Stations: Rigid support frames for positioning systems and welding torch manipulators

- Inspection & Quality Control Robots: Precision frames for coordinate measuring systems and automated vision inspection

- Agricultural Robotics: Rugged structural frames for autonomous tractors, harvesters, and field monitoring platforms

- Defense & Tactical Robots: Military-grade frames for EOD robots, reconnaissance platforms, and unmanned ground vehicles

E. Why Choose Yicen Precision for Custom Structural Frames?

Yicen Precision delivers specialized expertise in manufacturing complex custom structural frames with rapid turnaround times suitable for prototype development and production volumes. Our engineering team provides comprehensive Design for Manufacturability (DFM) consultation, optimizing frame topology, material selection, lightening strategies, and mounting feature placement for maximum performance and cost-efficiency. We maintain complete material traceability with certified mill test reports and material certifications for every structural frame component. Our scalable manufacturing capabilities handle frames ranging from compact cobot bases to large gantry structures exceeding 10 feet in length, with consistent quality standards throughout. Advanced inspection equipment including large-format CMMs, laser trackers, and granite surface plates ensure dimensional accuracy across entire frame assemblies. Cost-effective solutions are achieved through optimized machining strategies, efficient material utilization, and integrated multi-sided machining that reduces setup time and improves accuracy. Contact us for a custom quote and engineering consultation to discover how our precision structural frames can enhance your robotic system’s stability, accuracy, and performance.