Prototype CNC machining has become the go-to choice for engineers who need reliable, precise parts fast. When you’re developing a new product, every detail matters. That’s where CNC technology shines – it can create prototypes with tolerances as tight as ±0.0005 inches, which is pretty impressive when you think about it.

The numbers tell the story: the global CNC machine market hit $95.29 billion in 2024 and it’s expected to nearly double to $195.59 billion by 2032. Why such explosive growth? Simple – companies need automation and precision more than ever.

What Makes Prototype CNC Machining So Reliable

Here’s the thing about prototype CNC machining – it’s basically a computer-controlled cutting process that follows your CAD files exactly. No guesswork, no “close enough.” The machine does what the program tells it to do, every single time.

CNC prototypes start with your digital design. Engineers feed the CAD data into the machine’s computer, which then controls cutting tools to remove material precisely. What you get is a machined prototype that matches your specifications down to fractions of a millimeter.

The ASME Y14.5 standard sets the rules for how this all works. Think of it as the universal language that ensures everyone – from designers to machinists – is on the same page.

Why CNC Beats Other Prototyping Methods

Rapid prototyping using CNC offers some serious advantages:

- Accuracy that matters: Standard tolerances of ±0.005mm, with high-precision work reaching ±0.0005mm

- Speed when you need it: Simple parts can be ready in just one day

- Material flexibility: Over 100 materials to choose from, both metal and plastic

- Surface finish quality: Often good enough that you skip secondary finishing

But here’s what really sets CNC apart – you’re working with the same materials and processes you’ll use in production. That means your prototype behaves like the real thing.

Understanding CNC Machining Service Options

A good CNC machining service isn’t just about cutting metal. Today’s machine shops offer integrated solutions that can take you from CAD file to finished prototype in days, not weeks.

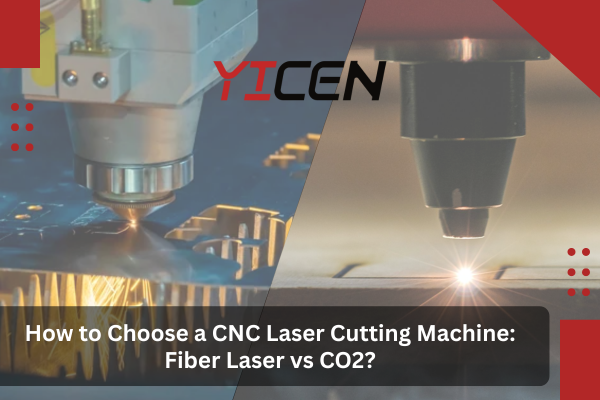

Machining centers have evolved into sophisticated operations. Take 5-axis CNC machines – these can cut complex angles and undercuts in a single setup. What used to require multiple machines and setups now happens in one operation.

Manufacturing Process Comparison

| Method | Velocidad | Precisión | Material Options | Best For |

| CNC milling | 1-3 days | ±0.005mm | 100+ options | Functional testing |

| 5-axis machining | 2-5 days | ±0.002mm | Aerospace grades | Complex geometries |

| Injection molding | 2-6 weeks | ±0.05mm | Limited plastics | High volume |

| Impresión 3D | Same day | ±0.1-0.3mm | 30+ materials | Design validation |

The subtractive manufacturing process of CNC gives you something 3D printing can’t – parts made from solid material with consistent properties throughout.

Getting Into the Details: Materials and Applications

CNC machining materials span everything from everyday aluminum to exotic titanium alloys. The choice depends on what your final product needs to do.

For aerospace applications, you might need titanium for its strength-to-weight ratio. Medical devices often require biocompatible stainless steel. Automotive prototypes might use the same aluminum alloys as production parts.

Plastic parts have their place too. Engineering plastics like PEEK can handle high temperatures that would melt other materials. ABS provides good impact resistance for consumer products. The machining process works with both, though metal generally holds tighter tolerances.

Real-World Material Selection

Here’s how materials typically break down:

Metal parts dominate when you need:

- Structural strength for load-bearing components

- Heat resistance for engine or processing equipment

- Corrosion resistance for marine or chemical applications

- Precise tolerances for mating surfaces

Plastic parts work better when you want:

- Weight reduction without sacrificing function

- Electrical isolation properties

- Cost-effective prototypes for design iteration

- Chemical compatibility with specific substances

Advanced CNC Capabilities Worth Knowing About

Modern CNC equipment does more than basic milling and turning. CNC routing handles both metals and plastics. 5-axis milling creates complex shapes that would be impossible with traditional methods.

CNC milling service providers often specialize in specific industries. Some focus on sheet metal fabrication for enclosures and brackets. Others excel at turned parts for shafts and fasteners. The best shops can handle whatever you throw at them.

The Business Side: Quotes, Lead Times, and Costs

Let’s talk about the practical stuff. Most modern shops offer an instant quote system where you upload your CAD file and get pricing in minutes. This transparency helps with project planning and budget approval.

Lead times vary based on complexity and shop workload. Simple milled parts might be ready in 24 hours. Complex 5-axis work takes longer – typically 2-5 days. Turnaround time also depends on material availability and any special finishing options you need.

Custom prototypes cost more than production parts – that’s just economics. But the investment pays off when you catch design issues early. It’s much cheaper to revise a prototype than to retool for production.

Cost Factors That Actually Matter

Here’s what drives CNC prototype costs:

Tolerance requirements have the biggest impact. Standard ±0.13mm tolerances are the baseline. Tighter specs cost 15-30% more. Ultra-precise work can double the price.

Material choice affects both machining time and raw material costs. Aluminum machines easily and costs less. Titanium requires specialized tooling and runs slowly, driving up costs significantly.

Complexity matters too. Simple rectangular blocks machine quickly. Parts with deep pockets, thin walls, or intricate features take longer and may require special tooling.

Quality Control and Finishing Options

Quality control in CNC isn’t just final inspection – it starts with material certification and continues through every machining operation. Precision machining requires constant monitoring and adjustment.

Finishing options can enhance both function and appearance:

- Anodize coating adds wear resistance and color to aluminum

- Powder coating provides durable, attractive finishes on many metals

- Precision grinding achieves ultra-smooth surfaces for sealing applications

- Corrosion resistance treatments extend part life in harsh environments

Industry Applications: Where CNC Prototyping Shines

Applications of CNC technology span virtually every industry that makes physical products. Aerospace demands the highest precision – safety-critical parts can’t have tolerance issues. Prototype CNC machining lets engineers validate designs before committing to expensive tooling.

Medical device prototypes need biocompatible materials and sterile processing capabilities. Automotive applications balance cost against performance requirements. Consumer electronics require precise fits and attractive finishes.

Mass production often starts with CNC prototypes. Once the design is proven, manufacturers might switch to injection molding for plastic parts or investment casting for complex metal components. But CNC remains the starting point for functional validation.

Making the Right Choice for Your Project

CNC machining is the best choice when you need functional prototypes that behave like production parts. The subtractive process gives you solid material properties throughout the part. Range of materials means you can match production specifications exactly.

Prototyping allows rapid design iteration without expensive tooling commitments. Custom parts can be in your hands in days, letting you test and refine designs quickly. End-use parts machined from production materials give you confidence in your design decisions.

The key is working with a prototyping service that understands your industry and applications. CNC technology keeps advancing, but experienced machinists know how to apply it effectively.

Working with Yicen Precision

Yicen Precision combines CNC machining capabilities with industry expertise to deliver custom CNC machined parts that meet demanding specifications. Their 5-axis equipment handles complex geometries while maintaining tight tolerances.

What sets them apart is their prototyping service approach – they work with engineers throughout the development process, offering design feedback and manufacturing insights. Parts in as fast as one day for urgent projects, with instant quote capabilities for quick project evaluation.

Their integrated services support both prototypes and production parts, making the transition from development to manufacturing seamless. Quality systems ensure machined parts meet specifications consistently.

Conclusión

Prototype CNC machining delivers the accuracy and reliability modern product development demands. When you need functional prototypes that perform like production parts, CNC technology provides the answer.

The manufacturing process continues evolving, but the fundamentals remain solid – computer-controlled precision, material versatility, and the ability to make prototypes that validate designs effectively. For engineers serious about product development, Prototype CNC machining isn’t just an option – it’s essential.

Preguntas frecuentes

Why pick CNC over 3D printing for prototypes?

CNC machined parts come from solid material – no layer lines, no weak spots, no surprises. 3D printing is great for concept models, but when you need a prototype that behaves like the real part, CNC wins every time.

How fast can you actually get Prototype CNC machining?

Simple machined prototypes can be done overnight if the shop isn’t swamped. 5-axis work takes longer because it’s more complex and fewer people can do it well. Figure 2-5 days for most stuff.

Which materials make sense for Prototype CNC machining?

Aluminum if you want metal parts that don’t break the bank. Steel when you need strength. For plastics, ABS handles most jobs, PEEK when things get hot. Pick based on what your actual product needs to do.

Will my CNC prototype work for production?

That’s the beauty of it – same process, same material, same properties. A CNC machined prototype gives you real confidence about how production parts will behave.

What finishing actually improves prototype performance?

Anodize makes aluminum harder and looks professional. Powder coating when you need durability. Precision grinding when sealing surfaces matter. Pick finishes based on function, not just looks.

Citations

- American Society of Mechanical Engineers. “ASME Y14.5 Dimensioning and Tolerancing.” https://www.asme.org/codes-standards/find-codes-standards/y14-5-dimensioning-tolerancing

- Fortune Business Insights. “CNC Machine Market Growth Analysis.” https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707

- International Organization for Standardization. “ISO 2768 General Tolerances.” https://www.iso.org

- Technavio Research. “Global CNC Machine Tools Market 2025-2029.” https://www.prnewswire.com/news-releases/cnc-machine-tools-market-to-grow-by-usd-21-9-billion-2025-2029