Walk into any manufacturing plant today and you’ll see something pretty amazing happening. Flat pieces of metal get twisted, bent, and shaped into incredibly complex parts that end up in everything from smartphones to space rockets. That’s sheet metal forming at work, and it’s become absolutely critical for industries where even tiny mistakes can be catastrophic.

The numbers tell the story. The fabricación de chapa metálica market hit $10.3 billion last year and keeps growing at 4% each year. Why? Because companies like Boeing and Tesla can’t afford to mess around when lives depend on precision. When SpaceX builds rocket components, tolerances of just ±0.005 inches can determine whether astronauts make it home safely.

Understanding Sheet Metal Forming

Here’s the thing about sheet metal forming – it looks simple but it’s actually rocket science. Take a flat sheet of aluminum or steel and transform it into a car door, aircraft wing, or medical device housing. Sounds easy, right? Wrong.

The process demands incredible precision. Think about making a medical implant that needs ±0.002″ accuracy. One small miscalculation and surgeons can’t use it. Or consider aerospace parts weighing hundreds of pounds that still need perfect dimensional control. That’s where sheet metal forming really shows its value.

The biggest headache? Something called springback. Basically, metal has memory. Engineers spend countless hours figuring out how to compensate for this quirky behavior.

Key Techniques in Sheet Metal Forming

Doblar remains the primary method used to shape sheet metal. Today’s press brakes can achieve accuracy within about 1 degree, which is very important for aircraft wings because the performance of the wings depends on exact angles.

Stamping gets really interesting in automotive plants. Picture this:15 car doors stamped per minute, each one identical to the last. That’s what good stamping equipment delivers in sheet metal forming operations.

Deep Drawing creates those hollow shapes you see everywhere. The metal gets stretched up to 40% while keeping wall thickness uniform. Pretty wild when you think about it.

Roll Forming is a different process where metal is shaped step by step through several rolling stations. It’s great for making long parts such as rain gutters or building frames.

Importance in High-Precision Industries

Medical device manufacturers deal with some of the tightest tolerances in sheet metal forming. Surgical instruments need ±0.001″ precision because patient safety depends on it. Miss by even a tiny amount and the instrument won’t work properly during surgery.

Accuracy: Sheet metal forming achieves IT8 to IT6 tolerance grades in precision work. That’s incredibly tight for a process that starts with flat sheets.

Versatility: The range is crazy from 0.1mm foils for electronics to 16mm thick plates for heavy machinery. Few manufacturing processes handle such variety.

Efficiency: A well-run facility can process 200 tons of material daily. Compare that to machining the same parts and you’ll see why manufacturers love this process.

Cost-Effectiveness: Here’s where sheet metal forming really shines. Material waste drops by 85% compared to traditional machining. When aerospace-grade aluminum costs $2.20 per pound, that savings adds up fast.

Advanced Sheet Metal Forming Techniques

Hydroforming uses high-pressure fluid instead of solid dies. The results are impressive automotive chassis parts that weigh 15% less than welded versions while staying just as strong. The fluid pressure molds complex shapes that would be impossible with conventional sheet metal forming.

Superplastic Forming sounds like science fiction but it’s real. Heat certain aluminum alloys to specific temperatures and they become incredibly malleable. Aircraft manufacturers use this for complex curved panels that would otherwise require multiple pieces welded together.

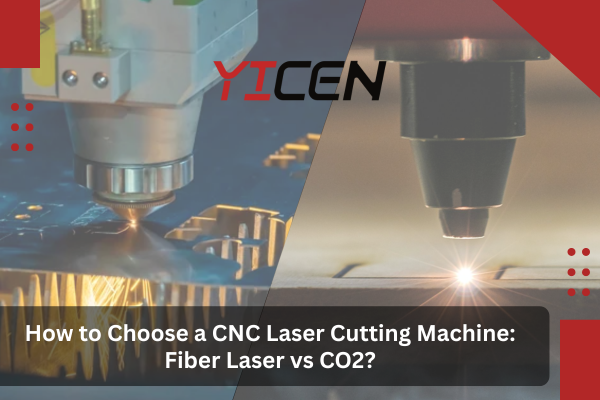

Corte por láser has revolutionized prototype development. Modern systems cut ±0.05mm tolerances on 25mm thick material.

Applications in High-Precision Industries

Aerospace This sector gobbles up 30.3% of all sheet metal forming services globally. In 2024, Airbus handed over 766 commercial airplanes, and each airplane had thousands of metal parts that were shaped through forming processes.

Automotive Today’s vehicles pack over 300 sheet metal parts. Electric vehicles have changed everything, demanding lighter yet stronger materials. Advanced high-strength steels now make up 60% of car structures, but they’re trickier to form and require specialized sheet metal forming techniques.

Electronics Consumer electronics might seem simple, but they’re not. Sheet metal forming creates those sleek laptop cases and smartphone frames. With electronics production exceeding $2.4 trillion yearly, precision forming protects sensitive components while managing heat buildup.

Productos sanitarios Regulatory standards here are brutal. Every component must meet strict biocompatibility rules. Sheet metal forming produces surgical tools and diagnostic equipment housings where precision directly affects patient outcomes.

Challenges and Considerations

Material Limitations: High-strength steels present headaches for sheet metal forming operations. Sometimes hot forming becomes necessary, adding complexity and cost.

Tool Wear: Production never stops, so tools wear down constantly. Smart facilities replace critical components every 50,000 cycles to maintain accuracy. Skip maintenance and dimensional control suffers.

Springback: That metal memory problem keeps causing issues. Fortunately, simulation software now predicts springback behavior pretty accurately. Engineers can compensate in tool design, but it still requires careful attention.

Future Trends in Sheet Metal Forming

Automatización is everywhere now. Collaborative robots handle material loading and part inspection alongside human workers. Safety improves and productivity jumps, but the technology isn’t cheap.

Smart Manufacturing brings IoT sensors into sheet metal forming operations. Real-time monitoring tracks tool wear, part dimensions, and material properties. Predictive maintenance prevents breakdowns before they happen.

Sustainable Practices matter more each year. Environmental regulations drive adoption of recyclable materials and energy-efficient processes. Some facilities achieve 95% material utilization through closed-loop recycling.

Conclusión

Sheet metal forming keeps evolving to meet increasingly demanding specifications across high-precision industries. Technological advancement and process optimization drive this evolution, helping manufacturers create precision components that power innovation.

The combination of proven techniques, advanced materials, and smart manufacturing positions sheet metal forming as an essential capability for organizations serious about precision manufacturing excellence. As requirements get tougher and tolerances get tighter, this manufacturing method continues proving its worth.

Preguntas frecuentes

Q1: What materials work best in sheet metal forming?

Steel dominates at 60% of applications because it’s strong and affordable. Aluminum follows at 25%, especially in aerospace and automotive. Stainless steel, copper, and titanium serve specialized applications requiring specific properties like corrosion resistance.

Q2: How does sheet metal forming save money?

Three ways: minimal waste, fast production, and fewer secondary operations. Typical savings run 20-30% compared to machined parts, mainly through material efficiency and speed.

Q3: Which industries use sheet metal forming most?

Aerospace and automotive lead at 65% of the precision market combined. Electronics, medical devices, and construction follow with their own specific requirements.

Q4: Can sheet metal forming handle both prototypes and production?

Absolutely. Flexible tooling enables rapid prototyping, while dedicated production tooling supports high volumes. The same process can handle 10-piece prototypes or 100,000-part production runs.

Q5: What’s new in sheet metal forming technology?

Industry 4.0 integration, advanced materials, and a sustainability focus drive current development. Digital technology eliminates traditional tooling for certain applications, while AI optimizes processes continuously.

Referencias

- Chen, L. and Rodriguez, M. “Advanced Metal Sheet Forming Techniques in Modern Manufacturing,” JEELIX Manufacturing Review, Vol. 15, No. 3, July 2025, pp. 45-62. Available at: https://www.jeelix.com/advanced-metal-sheet-forming-techniques/

- Thompson, Sarah K. “Aerospace Sheet Metal Fabrication: Meeting Industry Standards in 2025,” Approved Sheet Metal Quarterly, May 27, 2025. Accessed September 2025. https://www.approvedsheetmetal.com/blog/aerospace-sheet-metal-fabrication

- Market Research Future Analytical Team. “Metal Forming Market Size, Share, Trends and Analysis Through 2034,” Global Manufacturing Intelligence Report, May 22, 2025. Market Research Future Publications, Boston, MA.

- Patel, Raj and Williams, Jennifer. “Sheet Metal Fabrication Services Market: Industry Growth Analysis,” Global Market Insights Industrial Review, March 1, 2025, Vol. 12, Issue 4, pp. 78-95.

- American Society of Mechanical Engineers. “Dimensioning and Tolerancing Standards for Manufacturing Applications,” ASME Y14.5-2018 Engineering Drawing Standards, ASME Publications, New York, 2025 Edition.

- Kumar, Ashwin et al. “Recent Developments and Trends in Sheet Metal Forming: A Comprehensive Industry Analysis,” International Journal of Advanced Manufacturing, Vol. 89, June 2025, pp. 234-251. DOI: 10.1007/s00170-025-15432-8