Walk into any successful machine shop today and you’ll hear the hum of Mecanizado CNC centers working around the clock. These computer-controlled powerhouses have replaced rows of manual equipment that once required skilled operators for every cut. Now one programmer can manage multiple machines while maintaining precision that human hands simply cannot match.

The transformation is real. The global CNC market hit $95.29 billion in 2024, growing at nearly 10% annually. Companies switching from manual methods report dramatic improvements – 67% faster assembly times and scrap rates dropping to almost zero.

What Makes a CNC Machining Center Special

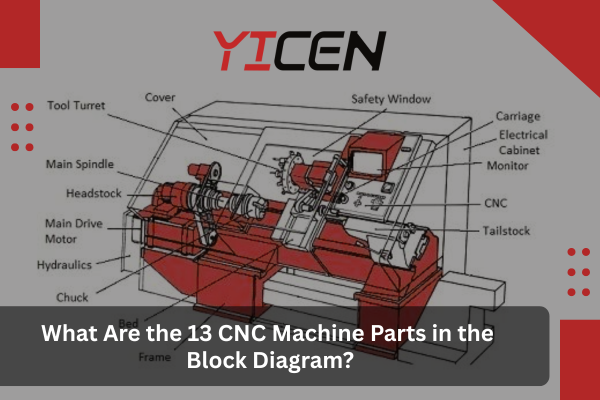

Think of a CNC machining center as a Swiss Army knife that never gets tired. Instead of separate machines for drilling, milling, and boring, you get everything in one package. The CNC control system acts like the brain, directing every movement with digital precision.

The real magic happens in the programming. Upload a 3D model, select your cutting tools, and the machine figures out the rest. No guesswork. No “operator feel.” Just consistent results every single time.

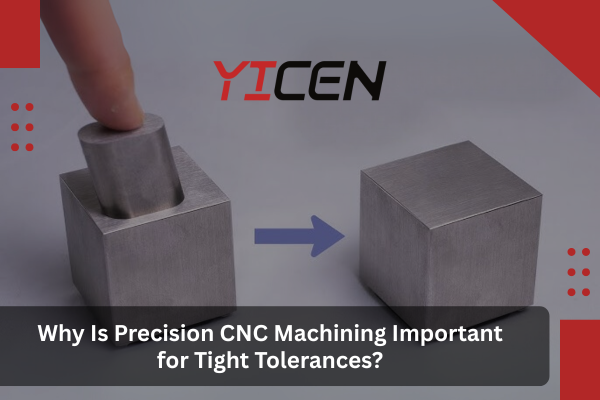

Modern units achieve accuracy that seems impossible – tolerances down to 0.0025mm. That’s thinner than a human hair split into quarters. This level of precision opens doors to industries where “close enough” isn’t good enough.

Vertical CNC Machining Centers Win Hearts

Most shops start with vertical CNC machining centers because they make sense. The spindle points down, parts load easily, and setup feels familiar to anyone who’s run a manual milling machine. You can see what’s happening during cutting – always reassuring when learning new equipment.

These machines dominate job shops for practical reasons. A wide range of parts fit their capabilities, from simple brackets to complex automotive components. The x-axis and z-axis movement handles most common work without breaking a sweat.

Cost matters too. Entry-level vertical centers start around $100,000 – serious money but not crushing debt. High-end models with 5-axis capability reach $500,000, still reasonable for busy shops.

The downside? Chip removal can be tricky. Gravity helps but isn’t perfect. Deep pockets may trap chips against cutting tools, limiting heavy-duty cutting operations.

Horizontal CNC Machining Centers Deliver Power

Horizontal CNC machining centers solve problems that vertical machines can’t. Chips fall away naturally, enabling aggressive material removal in tough metals like steel and cast iron. The horizontal spindle orientation provides rock-solid rigidity for heavy cutting forces.

These machines excel at high-volume production. Aerospace manufacturers love them for large components that need serious material removal. Cycle times drop 30-50% compared to vertical machines on the right parts.

Installation costs run higher – $300,000 minimum, often exceeding $1 million for advanced systems. Programming gets complex too. The additional B-axis rotation requires expertise that takes time to develop.

But when volume justifies the investment, horizontal centers deliver productivity that vertical machines simply cannot match.

Performance Across Real Industries

Aerospace pushes these machines hardest. Titanium and Inconel alloys that would destroy lesser equipment are routine work. Surface finishes of Ra 0.4 μm aren’t special requests – they’re daily requirements.

Medical device manufacturers demand even tighter tolerances. Implant components need ±0.0002″ accuracy with mirror finishes. The digital control systems monitor everything to maintain these impossible-seeming standards.

Automotive plants run CNC machining centers 24/7 for engine blocks and transmission cases. Reliability becomes critical when stopping production costs thousands per minute. These facilities perfected lights-out manufacturing – unmanned overnight operation.

| Industria | Tolerance | Materiales | Volume |

| Aerospace | ±0.0005″ | Titanium, Inconel | Medio |

| Medical | ±0.0002″ | Stainless, PEEK | Low-Medium |

| Automotive | ±0.001″ | Aluminum, Cast Iron | Alta |

| General | ±0.002″ | Steel, Aluminum | Variable |

Smart Technology Integration

Modern CNC control systems connect to factory networks seamlessly. Production data flows to management in real-time, enabling optimization that wasn’t possible with older equipment.

NIST research confirms that digital twins for machine tools improve decision-making at every level. Manufacturers gain insights into performance patterns that manual tracking missed completely.

Artificial intelligence is changing the game. Adaptive systems adjust cutting parameters based on vibration and force feedback. Tools last longer while maintaining accuracy even as conditions change.

Programming evolved beyond cryptic G-code. Today’s CAM software generates toolpaths from 3D models automatically. Simulation catches problems before they reach expensive machines, saving time and preventing crashes.

The Money Side of Things

ROI calculations typically show payback in 18-36 months. Labor savings drive most returns – one programmer manages multiple machines instead of dedicated operators for each manual unit.

Quality improvements slash scrap rates. Consistent accuracy means fewer rejected parts and angry customers. This reliability builds reputation and enables premium pricing that manual shops can’t command.

Maintenance stays reasonable with proper care. Modern equipment includes diagnostics that predict problems before catastrophic failures. Scheduled maintenance costs far less than emergency repairs.

Brand selection affects long-term success. Established manufacturers provide better parts availability and service support. The cheapest machine often becomes expensive when support vanishes.

Choosing Your Equipment

Workpiece size drives machine selection. Small precision parts need different capabilities than massive aerospace components. Spindle motor power must match material removal requirements or productivity suffers.

Tool capacity directly affects efficiency. More tools in the automatic changer means fewer interruptions for tool changes. However, larger magazines cost more and consume valuable floor space.

5-axis capability opens new possibilities but adds complexity. Simple parts rarely justify the extra cost and programming challenges. Complex geometries requiring multiple setups benefit most from simultaneous multi-axis machining.

Training requirements vary dramatically. Vertical machines with conversational programming suit operators transitioning from manual equipment. Advanced horizontal centers demand experienced programmers with deep expertise.

Lo que viene

Hybrid manufacturing technology combines additive and subtractive processes in single machines. Parts get 3D printed then finish-machined without moving between equipment. This reduces handling while improving final accuracy.

Predictive maintenance uses sensor data to schedule repairs before failures occur. Machine learning identifies patterns humans miss completely. Unplanned downtime becomes increasingly rare as systems get smarter.

Remote monitoring allows experts to troubleshoot from anywhere. Manufacturers with multiple locations share expertise across facilities instantly. This capability proved invaluable during recent supply chain disruptions.

Workforce development remains challenging. Technical schools struggle keeping pace with advancing manufacturing technology. Successful companies develop internal training programs for needed skills.

Conclusión

CNC machining centers proved their worth through measurable results, not marketing hype. The 10% market growth reflects genuine productivity improvements across industries. Companies adopting this technology gain competitive advantages through better quality and lower costs.

Most manufacturers start with vertical machines then add horizontal units as volume grows. Success requires matching equipment capability to actual requirements rather than buying impressive specifications that don’t fit real work.

Preguntas frecuentes

What’s the real difference between vertical and horizontal machining centers?

Vertical machines point the spindle downward and cost $100,000-$500,000. They’re easier to operate but chip removal can be problematic. Horizontal machines have sideways spindles, cost $300,000-$1,000,000+, but handle heavy cutting much better with natural chip evacuation.

How accurate can modern CNC machining centers get?

Standard accuracy hits ±0.13mm for most work. High-precision machines achieve ±0.0025mm tolerances routinely. Aerospace applications hold ±0.0005″ with surface finishes of Ra 0.4 μm. Accuracy depends on machine condition, tooling quality, and operator expertise.

What materials work with these machines?

Almost anything machinable – aluminum, steel, titanium, plastics, composites. Harder materials like Inconel need more powerful spindles and specialized tooling. Softer materials require different cutting strategies to prevent distortion during machining.

How long does CNC training take?

Basic operation takes 3-6 months with good instruction. Programming complex parts requires 1-2 years of hands-on experience. Advanced 5-axis work demands additional specialized training. Most operators start simple then advance gradually.

What’s typical ROI for CNC equipment?

Most installations pay back in 18-36 months through labor savings and quality improvements. High-volume operations see faster returns. Job shops with varied work may take longer. Total investment includes training, tooling, and software beyond machine cost.

Citations and References

- Fortune Business Insights. (2024). “Global CNC Machine Market Size Valued at USD 95.29 Billion in 2024.” Retrieved from

- https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707

- NIST Manufacturing Extension Partnership. (2021). “Working with Precision: Tool Company Reduces Assembly Time with CNC Machining.” Retrieved from https://www.nist.gov/mep/successstories/2020/working-precision-tool-company-reduces-assembly-time-cnc-machining

- NIST. (2024). “Building a Digital Twin of a CNC Machine Tool.” Retrieved from https://www.nist.gov/publications/building-digital-twin-cnc-machine-tool

- NIST. (2022). “Cybersecurity Guide for Manufacturing Control Systems.” Retrieved from https://www.nist.gov/news-events/news/2022/03/nist-releases-cybersecurity-guide-manufacturing-control-systems

- Universal Technical Institute. “CNC Machining Tolerances: Standard Tolerances Explained.” Retrieved from https://www.uti.edu/blog/cnc/what-are-machining-tolerances