Precision CNC machining delivers components that meet exact specifications through computer numerical control manufacturing processes. This advanced machining process eliminates dimensional variations while maintaining consistent precision and quality across production batches. Aerospace industries and other sectors depend on precision CNC machining services because standard manufacturing methods cannot achieve the required high accuracy levels.

Boeing aircraft engines require machined components with tight tolerances within 0.0001 inches. Similarly, medical implant manufacturers need cnc parts that fit perfectly within human anatomy. Therefore, cnc precision machining becomes indispensable for applications where accuracy determines success or failure.

How Does CNC Precision Achieve Tight Tolerances

CNC precision uses computer numerical movements to position cutting tools with exceptional accuracy. Advanced servo motors control each axis movement while feedback systems monitor actual positions. Additionally, thermal compensation systems adjust for temperature changes that could affect dimensional accuracy during actual machining.

Key Technologies Enabling Precision Manufacturing

Several technological advances make high-precision cnc possible:

- Linear encoders providing position feedback within 0.1 microns for high-precision operations

- Ballscrew drives eliminating backlash during direction changes in cnc machines

- Spindle temperature monitoring maintaining consistent cutting conditions on precision cnc machines

- Vibration damping systems reducing tool chatter effects during machining operations

Furthermore, Yicen Precision implements climate-controlled manufacturing environments. Their cnc machine shop maintains temperature variations within ±1°C to prevent thermal expansion affecting workpiece dimensions during production processes.

What Industries Benefit Most from Precision CNC Manufacturing

Precision cnc manufacturing serves sectors requiring strict dimensional control. Industries including automotive, medical, and aerospace cannot function without components meeting exact specifications:

| Industria | Typical Tolerance | Critical Applications |

| Aerospace | ±0.0002″ | Turbine blades, satellite components |

| Medical | ±0.0001″ | Joint replacements, implant devices |

| Semiconductor | ±0.00005″ | Wafer handling equipment |

| Automotive | ±0.001″ | Engine blocks, transmission gears |

Aerospace Manufacturing Requirements

The Federal Aviation Administration mandates specific tolerances for aircraft components. Engine manufacturers like Pratt & Whitney require precision cnc machining for complex parts production. These machined part components operate at temperatures exceeding 2000°F while spinning at 15,000 RPM. Even microscopic dimensional errors in cnc machined parts cause catastrophic engine failures.

Medical Device Standards

The Food and Drug Administration requires medical devices to meet stringent quality standards. Hip replacement implant components must fit within 0.05mm tolerance to ensure proper bone integration. Therefore, cnc precision machining becomes essential for patient safety and device longevity across various types of cnc applications.

Why Do Tight Tolerances Matter in Manufacturing Parts

Tight tolerances ensure proper component fitment while preventing premature failures. Manufacturing parts outside specifications create assembly problems and reduced product performance. Moreover, precision cnc machining eliminates costly rework by producing accurate cnc parts initially.

Research from MIT demonstrates that manufacturing precision directly correlates with product reliability¹. Components with tighter tolerances exhibit 40% longer operational life compared to standard machined parts. Consequently, manufacturers save money through reduced warranty claims and improved customer satisfaction.

Economic Impact of Precision Manufacturing

Precision cnc machining provides measurable cost-effective benefits:

- Assembly time reduction by 25% when parts fit properly

- Quality rejection rates below 0.1% versus 3-5% for conventional methods

- Tool replacement costs decreased through optimized cutting parameters

- Energy consumption reduced via efficient machining capabilities

How Does Yicen Precision CNC Machining Company Deliver Results

Yicen Precision operates as a leading precision cnc machining company with cnc equipment featuring advanced measurement systems. Their coordinate measuring machines verify dimensions within 0.001mm accuracy. Additionally, they maintain ISO 9001:2015 certification demonstrating consistent quality control management practices.

The company provides comprehensive cnc machining service including multi-axis milling, precision cnc turning, and custom fixture manufacturing. Moreover, Yicen Precision handles machining project requirements from single prototype development to high-volume production runs. Their prototipado rápido capabilities deliver precision machined parts within 24 hours when required.

Quality Assurance Systems

Yicen Precision employs comprehensive quality control protocols:

- Statistical process control monitoring dimensional trends

- First article inspection verifying initial production parts

- In-process measurements catching deviations immediately

- Final inspection reports documenting part compliance

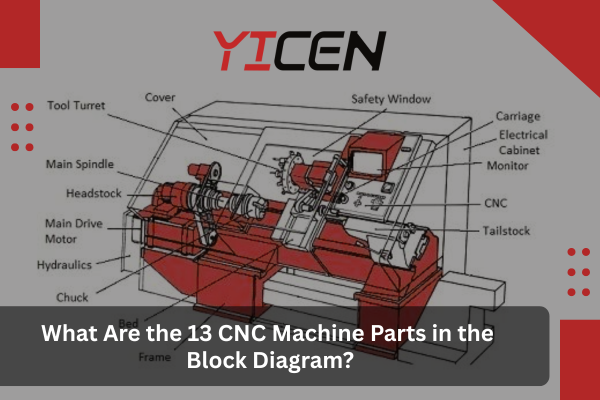

What Technologies Enable Advanced CNC Operations

Modern advanced cnc systems integrate multiple technologies. These precision machine systems work together maintaining accuracy throughout machining operations:

| Technology Component | Accuracy Achievement | Aplicación típica |

| Linear motor drives | ±0.1 micron positioning | High-speed milling |

| Laser measurement systems | ±0.5 micron verification | Real-time monitoring |

| Adaptive machining control | ±2 micron compensation | Aerospace componentes |

| Tool breakage detection | Immediate stop capability | Automatización operations |

Advanced Control Systems and CNC Programming

Contemporary cnc machine controllers process thousands of data points per second. These systems adjust cutting parameters automatically based on material conditions and tool wear patterns. Furthermore, predictive maintenance algorithms schedule tool changes before accuracy degrades, ensuring repeatability across production runs.

CNC programming sophistication enables 5-axis cnc operations producing complex shapes impossible with traditional 3-axis systems. Multi-axis capabilities allow complete workpiece machining in single setups, improving both accuracy and efficiency.

When Should Manufacturers Choose Precision CNC Services

Manufacturers select precision cnc machining services when standard methods cannot achieve tolerances required for complex parts. Applications involving safety-critical functions particularly benefit from this technology. Furthermore, cnc precision proves economical for both prototype development and high-volume manufacturing.

Consider precision cnc machining for projects requiring:

- Dimensional accuracy below ±0.005 inches using precise cnc methods

- Surface finishes better than 32 microinches Ra

- Geometric tolerances including concentricity and perpendicularity

- Material properties maintained through controlled machining process

Prototyping and Production Capabilities

Precision cnc machining accelerates product development by creating functional prototypes. Engineers test designs using precision methods with actual production materials and processes. Subsequently, design modifications happen before expensive tooling commitments occur.

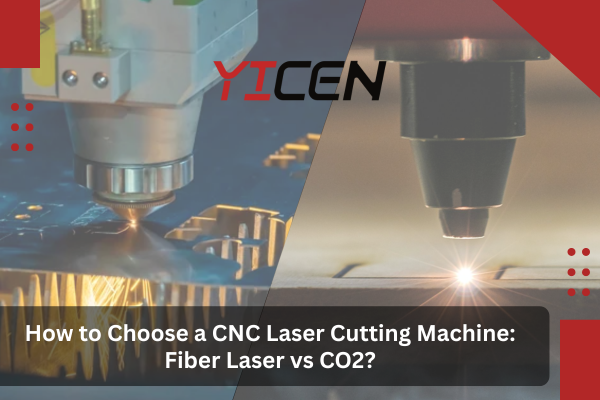

CNC milling operations produce identical parts with exceptional repeatability. Milling machine technology combined with cnc milling machine precision enables variety of materials processing including metals and plastics, alloy components, composite materials, and even exotic materials like tungsten.

Material Capabilities and Machining Uses

Precision cnc machines handle diverse material requirements across industries. Plastic cnc machining produces lightweight housing components while metal processing creates structural elements. Machining uses include cylindrical parts through cnc turning operations and precision cnc turning on advanced lathe systems.

5-axis capabilities enable complex parts machining including satellite components and defense equipment. Material machinability considerations include metals and plastics selection based on application requirements and customization needs.

Modern cnc machine shop operations integrate 3d printing for rapid prototyping with traditional machining for final parts. CAD file processing enables seamless transition from design to production while post-processing operations ensure complete part finishing.

Manufacturing Excellence Through Advanced Technology

Precision manufacturing combines cnc equipment sophistication with skilled operators. Supplier relationships ensure consistent material quality while automation reduces human error. High precision requirements drive continuous technology advancement in cnc machining capabilities.

Mill operations produce flat surfaces while cnc turning creates rotational geometry. 5 axis machining centers enable complete part processing reducing setup time and improving accuracy.

Conclusión

Precision CNC machining stands as the cornerstone of modern manufacturing excellence. This advanced technology enables manufacturers to produce complex parts meeting stringent quality requirements while maintaining cost-effective operations across industries. From aerospace components requiring extreme tight tolerances to medical implant devices demanding perfect accuracy, cnc precision machining delivers consistent results. Advanced cnc systems combined with skilled cnc programming ensure repeatability and high precision throughout production runs. Manufacturers investing in precision cnc manufacturing gain competitive advantages through superior precision and quality, reduced waste, and enhanced customer satisfaction. The integration of automation and multi-axis capabilities continues advancing machining capabilities, making precision cnc machining services essential for future manufacturing success.

Preguntas frecuentes

What accuracy levels does precision CNC machining achieve?

Precision cnc machining consistently produces cnc parts within ±0.001 inch tight tolerances. Advanced cnc systems achieve tolerances down to ±0.0001 inch for critical applications requiring extreme high precision.

How does precision CNC machining reduce manufacturing costs?

Precision cnc machining eliminates rework by producing accurate machined components initially. Additionally, automation reduces labor costs while maintaining consistent precision and quality across production runs.

What materials work best with precision CNC machining?

Aluminum alloys, stainless steel, and titanium respond well to cnc precision machining. Engineering plastics like PEEK and Delrin also machine to tight tolerances when proper techniques are applied during the machining process.

How quickly can precision CNC machining deliver parts?

Cnc machining service lead times depend on complexity and quantity. Simple prototype parts complete within 1-3 days while complex parts require 1-3 weeks for completion using advanced cnc systems.

What quality standards govern precision CNC machining?

Precision cnc manufacturing follows ISO 9001 quality control standards. Medical applications require ISO 13485 compliance while aerospace components need AS9100 certification for defense equipment applications.

Citations

- Massachusetts Institute of Technology. “Manufacturing Systems Research.” https://web.mit.edu/

- National Institute of Standards and Technology. “Precision Manufacturing Guidelines.” https://www.nist.gov/

- Stanford University. “Mechanical Engineering Manufacturing Studies.” https://www.stanford.edu/

- U.S. Food and Drug Administration. “Medical Device Manufacturing Standards.” https://www.fda.gov/