Introduction

Jig and fixture design is foundational in modern manufacturing, enabling high precision, repeatability, and efficiency in various industries. The detailed handbooks authored by Hoffman and Carr Lane remain critical resources for engineers, machinists, and tool designers. These books are essential references for those looking to understand the design principles, practical applications, and advanced techniques that drive production success.

Why Jig & Fixture Design Handbooks Matter Today

In today’s competitive manufacturing landscape, the need for fast production times, high precision, and cost-effectiveness has never been greater. Jig and fixture design handbooks, particularly those from Hoffman and Carr Lane, offer critical insights into how to design these tools for maximum efficiency. By mastering these principles, engineers can reduce errors, increase throughput, and optimize production costs, making these resources indispensable for any manufacturing process.

Importance for Manufacturing Engineers, Machinists, Tool Designers

Jig and fixture design books are vital for professionals in manufacturing. Engineers and machinists rely on them to:

- Achieve precise part alignment and repeatability.

- Design and implement effective clamping and locating systems.

- Reduce setup time and improve overall efficiency.

What Makes Hoffman + Carr Lane the Industry Standards

Hoffman and Carr Lane stand out due to their comprehensive coverage of fixture design principles and their real-world applications. These handbooks incorporate years of industry expertise, blending theoretical knowledge with practical shop-floor strategies. They are recognized for their attention to detail, user-friendly explanations, and a robust approach to both simple and complex fixture designs.

Overview of Hoffman’s Handbook of Jig & Fixture Design

Who is Hoffman? (Author Background + Authority)

Hoffman is a respected author and authority in the field of jig and fixture design. With decades of experience in manufacturing, his book provides a deep dive into both the theory and practical applications of fixture design, making it a timeless reference for engineers in various industries.

Core Philosophy of Hoffman’s Approach

- Process-Driven Design: Hoffman emphasizes a systematic, process-oriented approach to design, ensuring that each step is carefully considered for maximum functionality and efficiency.

- Standardization: Hoffman’s work advocates for standardizing components wherever possible, which simplifies the design process and ensures consistency across different production setups.

- Practical Shop-Floor Application: Hoffman focuses on designs that can be directly implemented on the shop floor, ensuring that the theories he presents translate into real-world solutions.

Key Topics Covered in the Hoffman Book

- Principles of Jig Design: Detailed guidelines on how to design jigs that improve usinage accuracy and reduce cycle time.

- Fixture Construction Fundamentals: Essential techniques and concepts for building sturdy, reliable fixtures.

- Locating Systems: A focus on how to use locator pins and other tools to ensure parts are accurately positioned.

- Clamping Systems: Detailed coverage of how to select and design the right clamping systems to securely hold workpieces during operations.

- Tool Guiding Methods: Insights into how jigs guide tools for precise machining and drilling.

- Bushings, Templates, Plates: Coverage on these vital components for guiding tools and securing workpieces.

Why Hoffman’s Book Is Still Relevant

The timeless principles laid out in Hoffman’s book make it as relevant today as when it was first published. By focusing on fundamentals like dimensional accuracy and repeatability, Hoffman provides engineers with the tools needed to design jigs and fixtures that can stand the test of time. Real-world examples and applications make the content practical, allowing engineers to apply the techniques in a modern manufacturing context.

Summary of Carr Lane’s Jig & Fixture Handbook

About Carr Lane (Industry Leader)

Carr Lane is a leading name in manufacturing, known for providing high-quality tooling components and fixtures for a wide range of industries. Their handbook reflects this legacy, providing comprehensive knowledge that covers everything from basic principles to advanced fixture design.

Major Chapters & Concepts

- Jig vs Fixture Definitions: Carr Lane provides a detailed comparison, emphasizing the differences in function between jigs (which guide tools) and fixtures (which hold workpieces in place).

- Types of Jigs:

- Template Jigs: Simple jigs used to guide tools along pre-drilled paths.

- Plate Jigs: These use a flat plate and guide the tool using holes or bushings.

- Table Jigs: Fixtures designed for large or heavy parts.

- Indexing Jigs: Used to rotate parts to different machining positions.

- Multi-Station Jigs: Used for processing multiple parts simultaneously.

- Template Jigs: Simple jigs used to guide tools along pre-drilled paths.

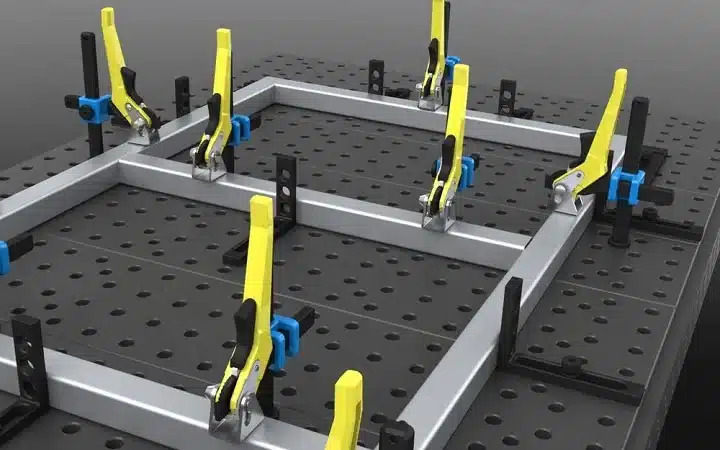

- Types of Fixtures:

- Plate Fixtures: These are flat fixtures used to hold workpieces in place during various machining operations.

- Angle-Plate Fixtures: Used to hold workpieces at specific angles.

- Welding Fixtures: Specialized fixtures that hold parts in place during welding to prevent distortion.

- Inspection Fixtures: Used for checking the accuracy of parts after machining.

- Plate Fixtures: These are flat fixtures used to hold workpieces in place during various machining operations.

Standard Components Covered in Carr Lane

Carr Lane’s handbook also covers standard components commonly used in fixture design, including:

- Tool Bodies

- Tooling Plates

- Precision Cast Sections

- Angle Brackets

- Hoist Rings

- Inserts & Keys

Why Carr Lane Handbook Dominates Industry

Carr Lane’s in-depth coverage of component-level details makes their handbook a critical reference for professionals. Its emphasis on using standard hardware allows fixture designers to streamline their design process and make efficient use of readily available components. It is particularly useful for CAD designers and engineers looking for detailed, component-level guidance in fixture design.

Hoffman vs Carr Lane What Engineers Should Know

Differences in Style & Teaching Approach

- Hoffman: Focuses more on the theoretical underpinnings of jig and fixture design, making his book ideal for engineers seeking a comprehensive understanding of design principles.

- Carr Lane: Offers a more practical, hands-on approach with a focus on real-world applications and component-level detail, making it better suited for professionals looking for direct, actionable guidance.

Which One is Better for Students?

For students, Hoffman’s book is better as it provides a thorough understanding of design principles and processes that are critical in the early stages of learning jig and fixture design.

Which One is Better for Industry Professionals?

Carr Lane’s handbook is better for industry professionals, especially those focused on implementing designs using standard components and working with CAD tools.

When to Use Both for Best Result

Combining both books is ideal. Hoffman’s approach will give students and professionals a strong theoretical foundation, while Carr Lane’s focus on standard components and practical applications ensures that designs can be translated directly into the workplace.

Jig & Fixture Design Fundamentals (Combined Learning from Both Books)

Locating Principles (3-2-1 Method)

Le Méthode 3-2-1 is essential in fixture design to fix the workpiece in place by preventing movement along all six degrees of freedom. Both books cover this method in-depth.

Clamping Principles & Force Distribution

Both books provide extensive coverage on how to choose and design clamping systems that hold workpieces securely without applying excessive force.

Tolerances & Datums in Fixture Design

Understanding tolerances and datums is crucial for creating fixtures that maintain dimensional accuracy during production.

Tooling Material Selection

Both books emphasize the importance of selecting the right matériaux for jigs and fixtures based on the manufacturing process and the forces applied.

Safety, Ergonomics & Accessibility

Safety and ergonomics are critical in fixture design, and both books cover how to design for ease of use while maintaining safety standards in the workplace.

Modern Additions: CAD, CAE & Digital Fixture Design

3D Modeling for Jigs & Fixtures

Modern tools like CAD (e.g., CATIA, SolidWorks) have revolutionized fixture design by enabling rapid prototyping and testing of virtual models.

Simulation (FEA, Deflection, Clamping Stress)

Finite Element Analysis (FEA) is now widely used to simulate how fixtures will perform under stress, heat, and other conditions.

Design Automation Tools

Automation tools can now assist in creating fixtures by auto-generating designs based on specific parameters and constraints.

Modular & Reconfigurable Fixture Systems

Modular systems are gaining popularity, allowing for flexible, reconfigurable fixtures that can be adapted to different tasks without extensive redesign.

3D-printed Jig & Fixture Elements (Hybrid Approach)

The use of 3D printing is growing in fixture design, offering cost-effective, customized solutions that can be rapidly produced and tested.

Download Resources & PDFs (Legal Notes)

Is Hoffman Jig & Fixture Design PDF Available?

It is important to consult licensed versions of the Hoffman book through authorized retailers or university programs. Unauthorized downloads may violate copyright laws.

Carr Lane Catalogs & Handbooks PDF

Carr Lane’s catalog and handbooks are available directly from their website and authorized distributors. Always use official sources for accurate and updated information.

Safe Alternatives for Students

Students can access university modules or open-source guides as alternatives for learning basic jig and fixture principles without violating copyright.

Best Modern Books for Jig, Fixture & Press Tool Design

- Hoffman – Jig & Fixture Design

- Carr Lane – Jig & Fixture Handbook

- Joshi – Jigs and Fixtures

- Press Tool & Fixture Design Guides

Conclusion

Merging classical knowledge from Hoffman and Carr Lane with modern tools like CAD, CAE, and Impression 3D helps engineers tackle today’s complex manufacturing challenges. The principles from these handbooks remain invaluable for industries like CNC, automotive, aerospace, and high-volume production setups, ensuring that fixture designs are efficient, cost-effective, and sustainable.

FAQ

Which is the best jig & fixture design book?

The best book depends on your needs. Hoffman’s book is great for foundational knowledge and theory, while Carr Lane’s handbook is more practical and focused on component-level detail.

Is there a free jig & fixture handbook PDF?

While some educational resources are available for free, it’s crucial to access licensed versions of books like Hoffman and Carr Lane to ensure you’re getting accurate and legal content.

What is the difference between jig & fixture design?

A jig guides the tool to a specific position, while a fixture holds the workpiece in place. Both are essential for achieving precision in manufacturing, but they serve different roles in the process.

Can I learn jig & fixture design without workshop experience?

Yes, it’s possible to learn the fundamentals of jig and fixture design through books, CAD software, and simulation tools. However, practical workshop experience will be invaluable for understanding how designs function in real-world manufacturing environments.