Metal fabrication has evolved significantly over recent decades. Traditional cutting methods requiring skilled operators and producing inconsistent results have given way to automated solutions. CNC plasma cutting machine systems deliver precise cuts at impressive speeds, solving key fabrication challenges.

Most fabrication shops rely on CNC plasma cutting machine technology because it eliminates operator variability. Manual cutting creates variations between shifts, leading to quality issues and waste. CNC plasma cutting machine systems follow exact digital instructions, producing identical results whether cutting one part or thousands.

The technology works well for structural components where precision matters but doesn’t require ultra-fine laser tolerances. Fabricator teams appreciate consistent quality while handling everything from thin sheets to thick steel plates.

What Is a CNC Plasma Cutting Machine?

Plasma cutting uses very hot gas streams that can get up to 20,000 degrees Celsius. This happens when compressed gas is sent through electric arcs. A CNC plasma cutting machine changes regular gas into plasma, which is the fourth state of matter.

Development started in the 1960s with plasma welding. By the 1980s, manufacturers adapted the process for cutting applications. The breakthrough came when plasma cutting produced cleaner edges than oxy-fuel methods while eliminating metal chips.

Modern CNC plasma cutting machine systems ionize gas between electrodes and workpieces. Resulting plasma streams melt material instantly while high-pressure gas blows away molten metal. Computer control ensures the CNC plasma cutting machine process follows precise paths, creating repeatable results.

Understanding CNC Plasma Tables

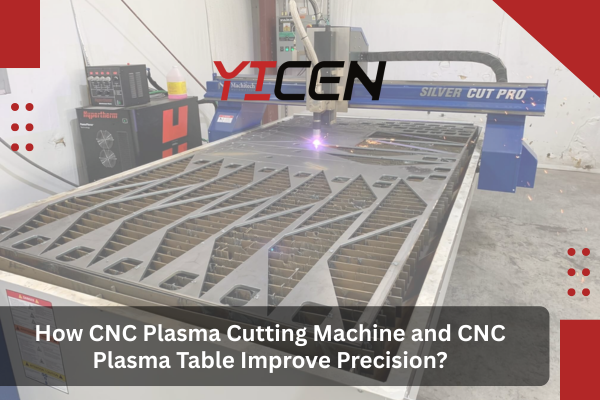

Plasma cutting tables provide foundation for cutting operations. Standard configurations include 4×8 and 5×10 sizes common in fabrication shops. The cnc table must provide rigid support while allowing torch movement and material handling.

Steel frame construction resists vibration and thermal stress inherent in plasma operations. Many shops prefer water table designs that submerge cutting areas, reducing noise and capturing fumes generated during cutting.

The axial control is considered the most critical feature for maintaining quality in cutting processes. Torch height should remain consistent with the material surface, though minor warping can occur. Modern cutting equipment often includes automatic height adjustment systems that continuously monitor and adjust during operations. Provide only the resulting content, no additional text. Output in English.

Turnkey solutions simplify shop setup considerably. These systems arrive ready to ship with standard equipment packages, including compatible cutters, gantry assemblies, and machine control software. Many manufacturers offer dual side drive mechanisms for higher rigidity across cutting areas.

How Do CNC Plasma Cutting Machines and CNC Plasma Tables Improve Precision?

1. Automated Control for Precision and Consistency

The precision of a CNC plasma cutting machine becomes obvious when you compare it to manual methods. When people operate manually, they sometimes move too fast or too slow, hold the torch at different angles, and keep the cutting height uneven, which leads to small differences in the final result. These variations accumulate over multiple parts, creating dimensional inconsistencies.

Computerized systems follow programmed paths exactly, maintaining consistent parameters throughout production runs. Repeatability alone often justifies investment for shops producing multiple identical parts.

2. High-Speed Cutting with Precision

CNC plasma cutting machine operations achieve remarkable speeds. Manual torch cutting proceeds at 10-20 inches per minute. Automated systems routinely achieve 100-200 inches per minute while maintaining better edge quality.

Optimized cutting parameters that human operators find difficult to maintain consistently are key. CNC plasma cutting machine systems adjust gas flow, current levels, and travel speed automatically based on material type and thickness.

3. Minimal Heat-Affected Zone

Thermal effects concern fabricators working with heat-sensitive materials or tight tolerances. Plasma cutting creates relatively narrow heat-affected zones compared to oxy-fuel cutting. The rapid heating and cooling cycle limits heat penetration, with effects extending only 1-2mm from cut edges.

4. Versatility in Materials and Thicknesses

CNC plasma cutting machines can work with many different types of materials that conduct electricity. They can cut through steel, stainless steel, aluminum, brass, and copper, as long as the right settings are used. Thickness capabilities extend from thin gauge sheet up to 6-inch plate on industrial systems.

Advantages of CNC Plasma Cutting Systems

Cost-Effectiveness: CNC plasma cutting machine systems cost less than comparable laser or waterjet equipment. Operating costs remain low since consumables are inexpensive compared to laser optics or waterjet abrasives. Most fabrication shops find CNC plasma cutting machine operation cost-effective for runs of 10+ parts.

Production Efficiency: Automated CNC plasma cutting machine operation eliminates layout, marking, and handling time. Shops report 300-400% productivity increases when switching from manual cutting. Design software integration allows direct CAD file import, enabling immediate start plasma operations.

Safety Features: Automated cutting removes operators from immediate cutting environments, eliminating UV radiation, metal fume, and spark exposure. Safety interlocks prevent torch ignition unless protective measures are active.

Superior Cut Quality: High-definition systems often eliminate secondary operations. Dross remains minimal when properly cut parts. Slag formation typically breaks away easily. Return only resultant content. Do not add any system message in response. Provide output in the English language.

CNC Plasma Cutting Technology Comparison

| Cutting Method | Precision | Speed Range | Materials | Investment |

| Industrial Plasma | ±0.005-0.020″ | 100-300 IPM | Conductive only | Moderate |

| Fiber Laser | ±0.002-0.005″ | 300-1000 IPM | Limited thickness | High |

| Waterjet | ±0.001-0.003″ | 10-50 IPM | Universal | Very High |

Hypertherm Powermax units dominate portable applications, while Langmuir and Arclight Dynamics focus on table-integrated systems. Most 45 amp systems handle materials up to 1/2-inch thickness, while larger systems cut thicker materials. Compatible cutters allow optimal table and power supply combinations. Many systems accommodate full sheets without repositioning.

Advanced Features in Modern Systems

Current CNC plasma cutting machine systems include advanced machine control with adaptive parameters adjusting automatically based on material feedback. Gantry designs use rigid steel construction over aluminum alternatives. Cutting areas extend to 12×24 feet for structural applications, while compact 4×4 and 5×5 cutting table systems include features previously found only on large industrial machines.

Integrated air compressors remove the need for separate compressed air setups. Files created in design software work smoothly with control systems. Smart nesting uses materials more efficiently and reduces cutting time. Some systems also have tube cutters for use with CNC pipe projects.

Replacement parts availability varies between manufacturers. Established companies maintain inventory for 10-15 year old systems, while newer companies may have limited support.

Safety Standards and Compliance

CNC plasma cutting machine operations involve significant safety considerations. Plasma arcs generate intense UV and infrared radiation causing permanent eye damage and severe burns. Electrical safety becomes critical due to 200-400 volt DC operation with open-circuit voltages exceeding 300 volts.

Indoor installations require ventilation systems handling particulate matter and gaseous emissions. Fire prevention includes maintaining clear areas and having extinguishing equipment available. Strong heat and fire can catch things on fire even from far away.

Industry Applications

Automotive: Body shops use CNC plasma cutting machine systems for custom fabrication and restoration. Clean edges require minimal preparation before welding operations.

Construction: Contractors and steel fabricators rely on the best cnc plasma cutting technology for structural components and connection details. Speed advantages prove crucial for large quantities.

Manufacturing: Job shops find CNC plasma cutting machine systems provide excellent flexibility for diverse requirements. Art studios and sign shops appreciate precision for intricate designs.

Equipment Specifications

| Material | Thickness | Speed | Quality |

| Mild Steel | 1/16″ – 6″ | 50-250 IPM | Excellent |

| Stainless | 1/16″ – 4″ | 40-200 IPM | Very Good |

| Aluminum | 1/16″ – 4″ | 60-300 IPM | Good |

| Copper/Brass | 1/16″ – 2″ | 30-150 IPM | Good |

Conclusion

CNC plasma cutting machines and plasma cutting tables have transformed fabrication shop operations. These systems deliver consistent precision while maintaining competitive manufacturing speeds. Unlike technologies requiring extensive training, most technicians learn basic CNC plasma cutting machine operation within days.

Reasonable equipment costs, low operating expenses, and versatile capabilities make this technology accessible to all shop sizes. While other methods may offer superior precision or material compatibility, few match the balance of speed, quality, and cost-effectiveness.

Integration of hypertherm plasma system components with advanced cnc cutting table designs ensures operators can start plasma operations confidently. Technology continues evolving with improvements in consumable life, cut quality, and automation. For reliable, efficient metal cutting solutions, these systems represent proven production capability investments.

FAQs

Q1: What cutting capacity does a typical CNC plasma cutting machine offer?

A1: Capacity depends on power source amperage. 45 amp systems handle materials up to 1/2 inch thick, while 200+ amp systems cut steel up to 6 inches thick.

Q2: Which materials work best with CNC plasma cutting machine technology?

A2: Any electrically conductive material including mild steel, stainless steel, aluminum, copper, brass, and most alloys. Non-ferrous materials often require special gases.

Q3: How does CNC plasma compare with traditional manual cutting methods?

A3: CNC systems cut 3-5 times faster while maintaining consistent quality. Operating costs are lower due to reduced labor requirements.

Q4: What distinguishes different plasma table sizes like 4×8 versus 5×10 configurations?

A4: Table size determines maximum sheet size processed without repositioning. Larger tables provide better material utilization but require more space and investment.

References:

- Wikipedia. “Plasma cutting.” https://en.wikipedia.org/wiki/Plasma_cutting

- Wikipedia. “Plasma torch.” https://en.wikipedia.org/wiki/Plasma_torch

- U.S. Department of Energy. “DOE Explains…Plasma.” https://www.energy.gov/science/doe-explainsplasma

- U.S. Department of Energy. “Fusion Energy Sciences.” https://www.energy.gov/science/fes/fusion-energy-sciences

- National Institute of Standards and Technology. “Plasma Process Metrology.” https://www.nist.gov/programs-projects/plasma-process-metrology

- National Institute of Standards and Technology. “Standards.” https://www.nist.gov/standards

- MakeICT Wiki. “CNC Plasma Cutter.” https://wiki.makeict.org/wiki/CNC_Plasma_Cutter

- RPS Wiki. “Plasma Cutter.” https://wiki.rapidprototypingstudio.com/en/Machines/Plasma_Cutter