In the high-stakes world of aerospace, there is no room for error. Every component must endure extreme conditions, maintain flawless reliability, and meet the tightest of tolerances. From commercial jets to advanced defense systems, aerospace manufacturing demands excellence at every step. That’s where Yicen Precision makes the difference.

At Yicen Precision, we provide advanced CNC machining services designed specifically for the complex and critical needs of the aerospace sector. With a strong emphasis on accuracy, consistency, and timely delivery, we empower aerospace engineers and manufacturers to transform ambitious concepts into production-ready components.

Why CNC Machining Is Essential for Aerospace Manufacturing

In aerospace, components are more than just mechanical parts they are mission-critical assets. Precision machining ensures these components meet the exact specifications needed to function safely in high-stress environments.

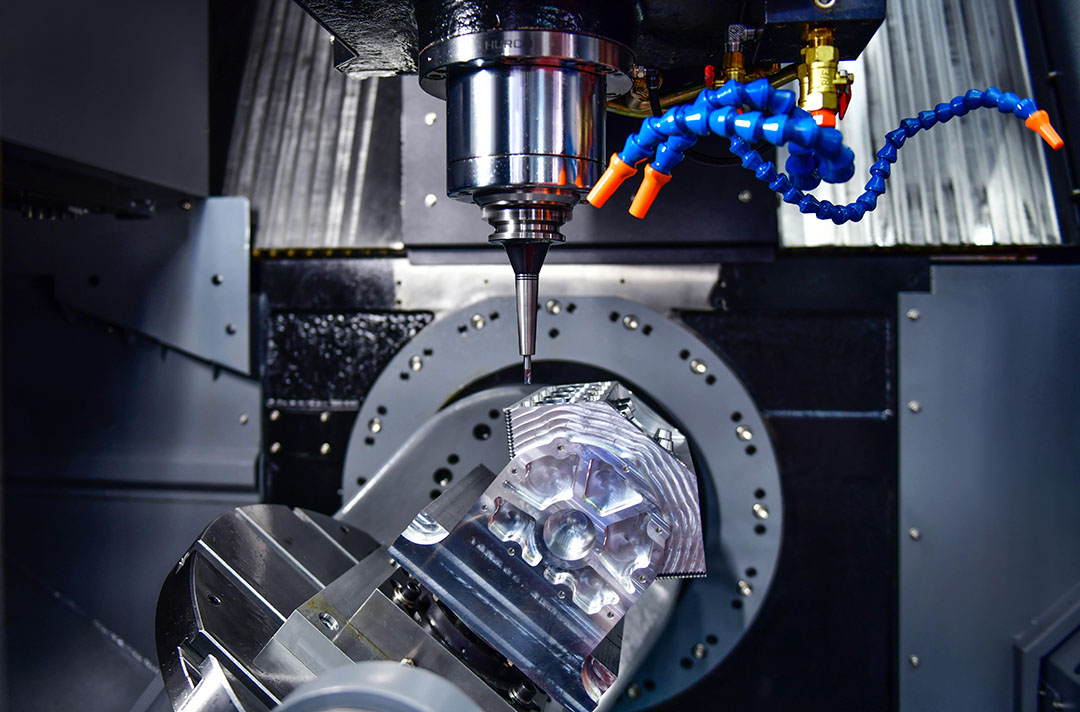

Yicen Precision utilizes cutting-edge 3-, 4-, and 5-axis CNC equipment to manufacture parts that adhere to aerospace-grade quality and performance expectations. Whether for prototype validation or high-volume production, our machining capabilities are trusted across the aviation and defense industries.

Core Advantages of CNC Machining for Aerospace Projects

- Exceptional dimensional accuracy for high-integrity assemblies

- Repeatable results across short-run and large-scale orders

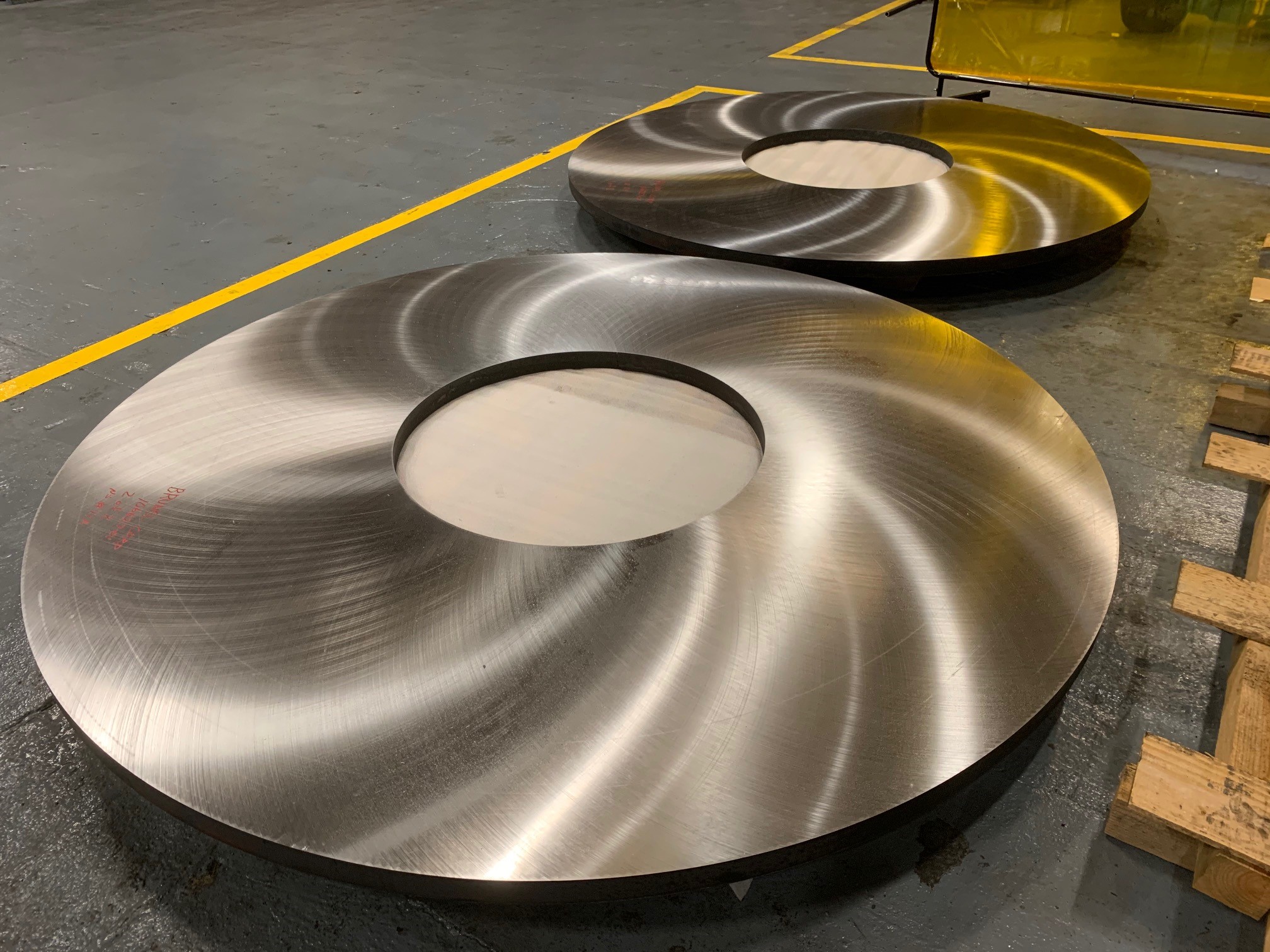

- Compatibility with aerospace alloys like titanium, Inconel, and aerospace aluminum

- Capability to create lightweight, complex geometries for aerostructures and subsystems

- Fast turnaround to meet development and delivery deadlines

Yicen Precision’s Aerospace Expertise

Yicen Precision offers a full suite of CNC manufacturing services tailored for aerospace clients. From one-off parts to recurring production, our process is designed for precision, traceability, and compliance.

Aerospace Prototyping Capabilities

Before a part ever flies, it must first be proven. Yicen delivers rapid CNC prototypes that replicate the real-world behavior of aerospace components. Using the same materials and tolerances as production models, our prototyping process helps engineers test functionality, fit, and durability.

Short lead times and flexible order volumes mean faster iteration cycles and reduced time to flight certification.

Production-Grade Aerospace Machining

Whether producing structural brackets or components for flight control systems, we meet the most stringent quality and repeatability standards. Yicen’s production CNC machining services support medium to high volumes, optimized for process stability and part consistency.

Common Aerospace Applications Include:

- Structural brackets and mounting supports

- Hydraulic and fuel system components

- Flight control hardware and linkages

- Enclosures and EMI shielding for avionics

- Space-ready components and ground equipment

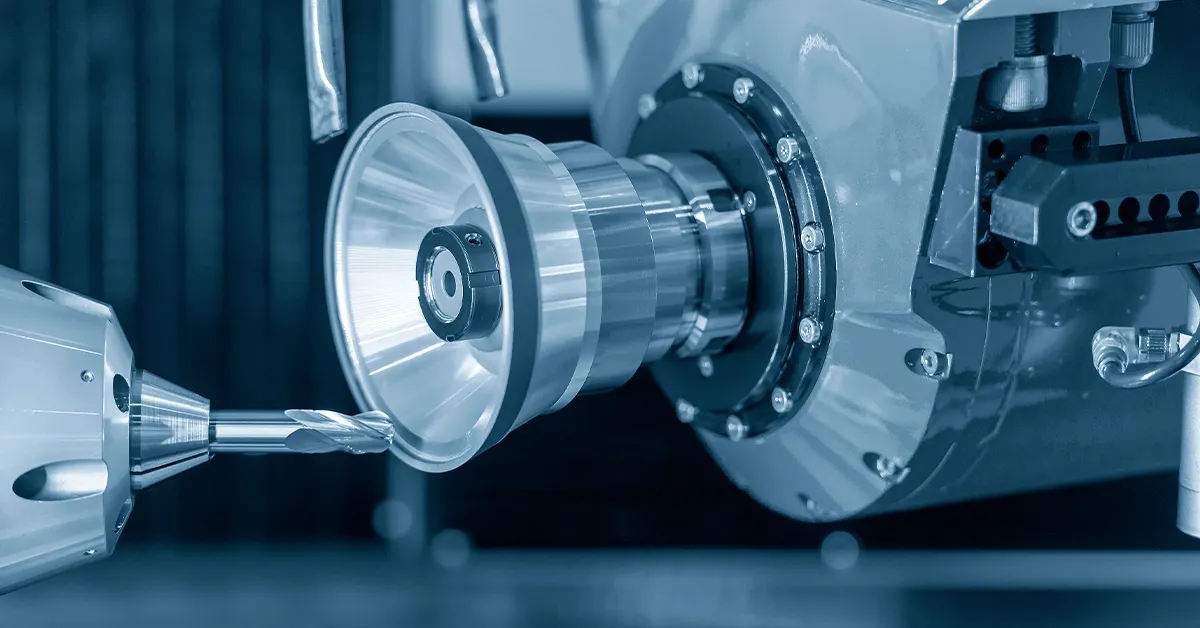

Precision Machining for Tight Tolerances and Complex Geometries

Aerospace components often require tolerances of ±0.001” or tighter. Yicen Precision excels in ultra-precise machining, using advanced simulation, toolpath control, and calibrated measurement tools to maintain the integrity of complex parts.

Our 5-axis CNC machines allow us to complete parts with internal cavities, aerodynamic surfaces, and compound angles in one setup ideal for reducing weight and assembly complexity.

Why Aerospace Manufacturers Choose Yicen Precision

Collaborative Engineering Support

We work alongside your engineers from day one, offering DFM feedback, tolerance reviews, and CAD model evaluations to optimize your parts for manufacturability without compromising performance.

Scalable Manufacturing Solutions

From prototype to production, Yicen ensures a smooth transition by preserving process documentation, fixture setups, and inspection protocols reducing ramp-up time and cost.

Precision Backed by Metrology

We rely on calibrated CMMs and inspection stations to verify every dimension and feature. This gives our clients peace of mind in the integrity of every shipment.

Built Around Aerospace Standards

Yicen Precision adheres to a quality-first approach that meets ISO 9001 standards and integrates aerospace-specific practices. We are continually enhancing our quality systems to meet the rigorous demands of AS9100 environments.

Let’s Build the Future of Aerospace Together

If your aerospace program demands high-tolerance, complex parts with documented quality and dependable delivery, Yicen Precision is ready to support you. Contact our team today for a technical consultation or a custom quote on your next aerospace machining project.