What are Actuation Components?

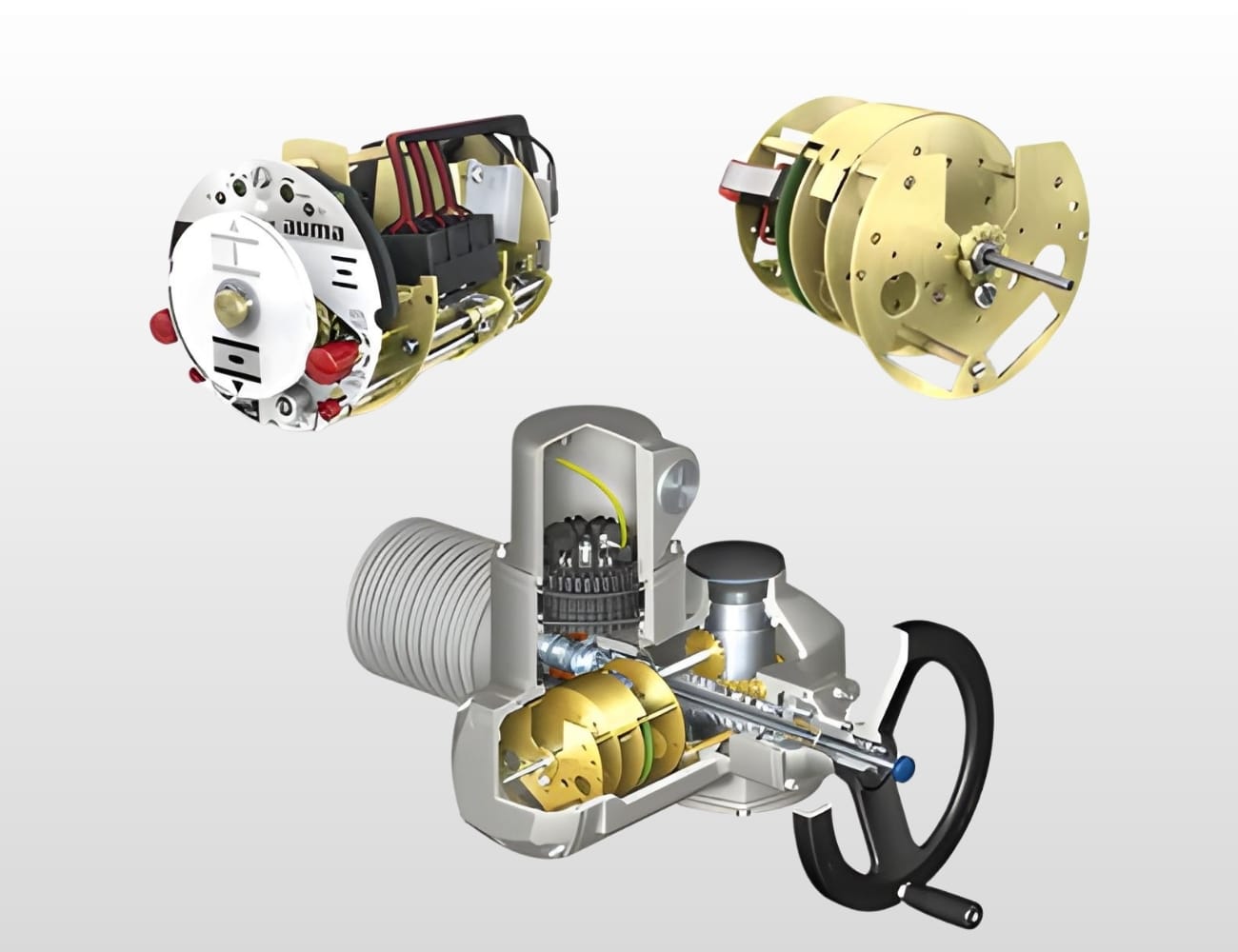

Actuation components are precision-machined mechanical elements that convert hydraulic, pneumatic, or electric power into controlled linear or rotary motion within aircraft control systems. These critical parts include actuator cylinders, piston rods, ball screw assemblies, valve bodies, servo housings, gimbal rings, clevis ends, and rotary actuator components used throughout commercial aircraft flight controls, military aircraft weapon systems, helicopter rotor controls, landing gear retraction systems, and thrust reverser mechanisms. Each aerospace actuation component must provide precise motion control, withstand high hydraulic pressures (3,000-5,000 PSI), resist wear and corrosion, and maintain sealing integrity. The performance of custom actuation components directly impacts aircraft maneuverability, system responsiveness, and operational safety across all flight regimes.

Key Technical Requirements

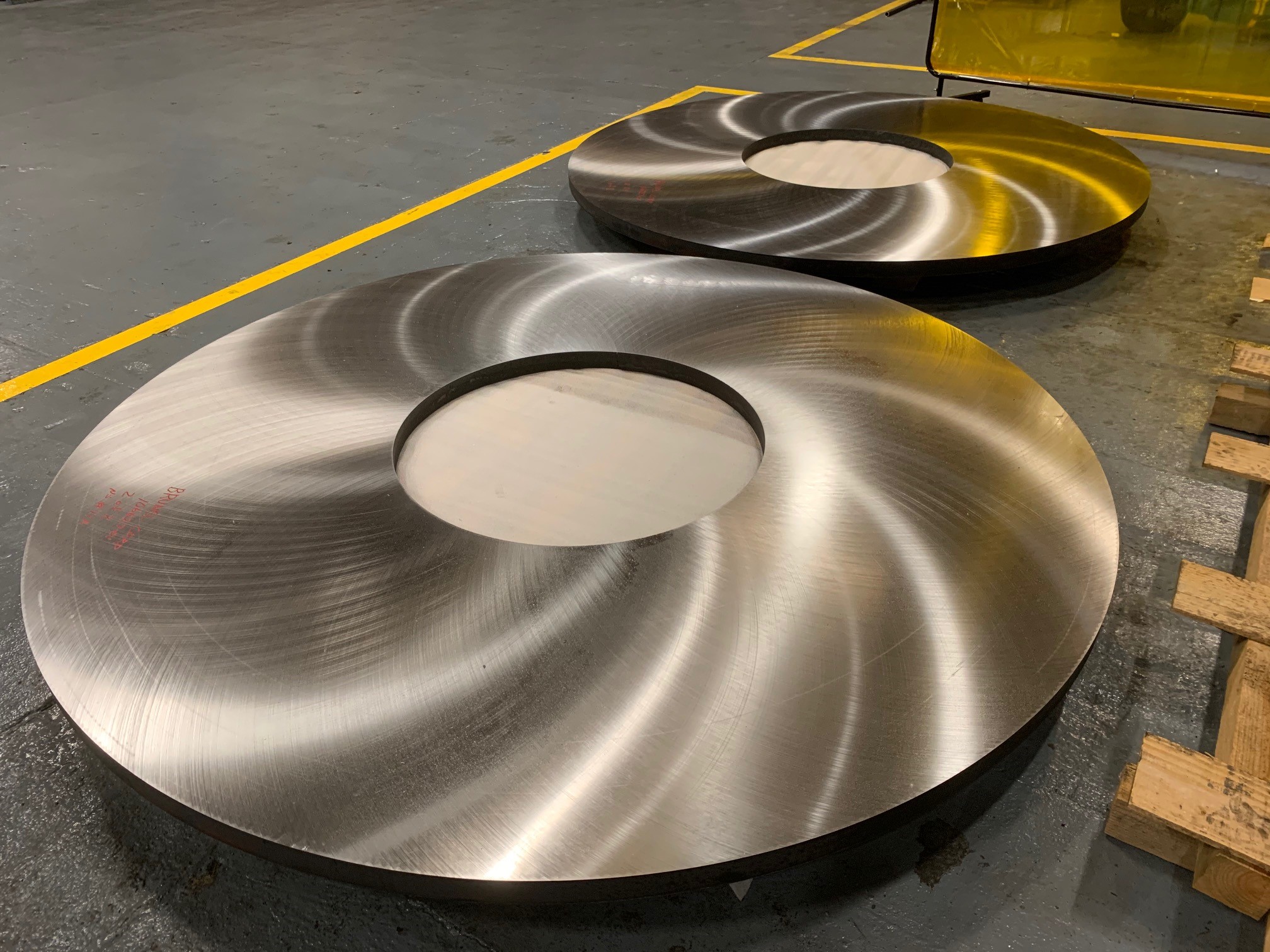

Manufacturing actuation components demands exceptional precision and surface quality. Typical tolerances range from ±0.002″ for housing features to ±0.0005″ for piston bore diameters, rod bearing surfaces, and sealing grooves that ensure proper hydraulic sealing and smooth motion. Material specifications require high-strength aerospace alloys including 17-4PH stainless steel (condition H1150, tensile strength 190 ksi), 15-5PH stainless steel for corrosion resistance, Ti-6Al-4V titanium for weight reduction, 4340 steel for high-load applications, and 6061-T6 aluminum for housings with complete material certifications.

Surface finish requirements are exceptionally demanding for sealing and bearing surfaces. Hydraulic cylinder bores require Ra 8-16 microinches with precise honing for seal compatibility. Piston rod surfaces demand Ra 4-8 microinches with controlled surface lay to prevent seal damage. Precision actuation components must withstand hydraulic system pressures up to 5,000 PSI, cyclic loading through millions of actuation cycles, side loads and moment forces during operation, and temperature ranges from -65°F to +200°F. Components require straightness tolerances on rods (typically 0.001″ per foot), bore concentricity within 0.002″ TIR, chrome plating or hard anodizing for wear resistance, and corrosion protection meeting ASTM B117 salt spray requirements exceeding 1,000 hours.

Manufacturing Challenges & Solutions

Machining actuation components presents unique technical challenges requiring specialized manufacturing expertise. Complex geometries including deep cylinder bores, precision sealing grooves, threaded connections, and multi-diameter shafts demand rigid setups and process control. Long, slender piston rods are susceptible to deflection and chatter during turning operations. High-hardness materials like 17-4PH condition H1150 require specialized tooling and cutting strategies.

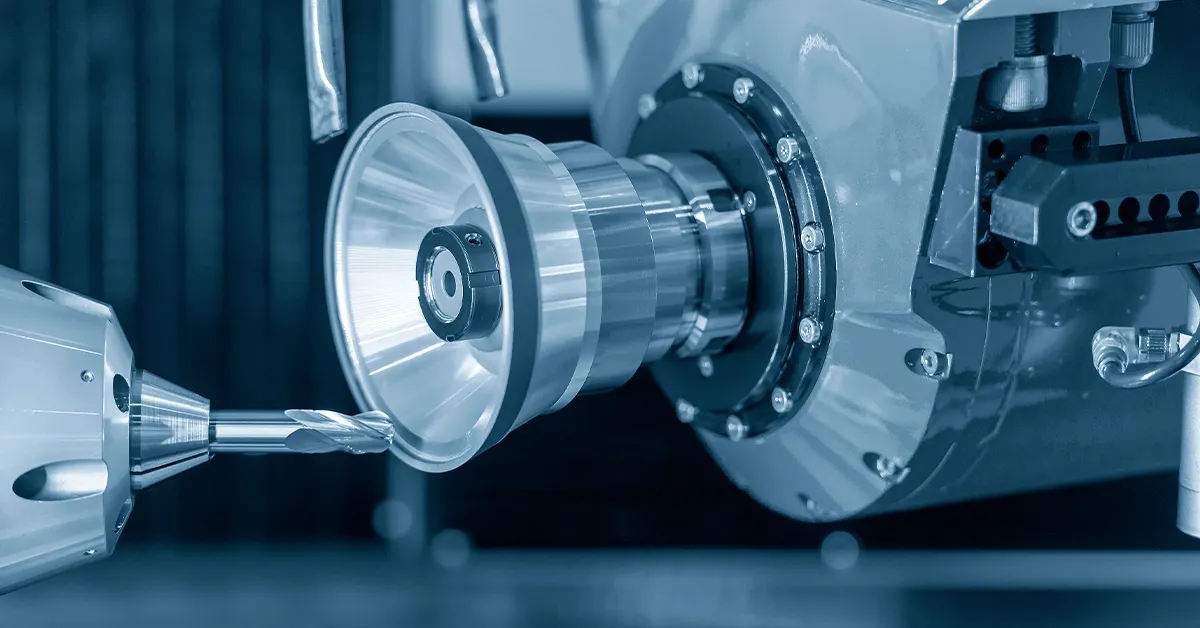

Yicen Precision overcomes these challenges through advanced manufacturing techniques and precision equipment. Our multi-axis CNC lathes with sub-spindle capabilities enable complete piston rod machining including turning, threading, and grooving in single operations, maintaining concentricity and straightness. Deep-hole boring and honing equipment produces hydraulic cylinder bores with precise diameter control and surface finish requirements. We utilize steady rests and tailstock support for long rod machining to prevent deflection while maintaining diameter tolerances.

Quality control protocols ensure actuation components meet all functional requirements. First-article CMM inspection verifies all critical dimensions including bore diameters, concentricity, and straightness measurements. Surface profilometry confirms cylinder bore and rod surface finishes meet hydraulic sealing requirements. We perform pressure testing on assembled actuator bodies to verify sealing integrity. Every custom actuation component receives comprehensive dimensional reports, material certifications, surface treatment documentation, and pressure test records ensuring complete compliance with aerospace hydraulic and electromechanical system standards.

Applications & Use Cases

Precision-machined actuation components enable critical motion control across diverse aerospace platforms:

- Flight Control Systems: Aileron, elevator, and rudder actuator components for primary flight control in Boeing 737/787 and Airbus A320/A350 aircraft

- Military Aircraft: Hydraulic actuator cylinders, servo valve bodies, and control surface actuators for F-16, F-18, and advanced fighter aircraft

- Landing Gear Systems: Retraction actuator components, gear door actuators, and nose wheel steering mechanisms for commercial and military aircraft

- Helicopter Rotor Controls: Swashplate actuators, blade pitch control components, and collective/cyclic actuation systems for rotorcraft

- Thrust Reverser Systems: Blocker door actuators, cascade deployment mechanisms, and thrust reverser lock actuator components

- Weapons Systems: Pylon actuators, weapons bay door mechanisms, and missile launch actuator components for tactical aircraft

- Space Vehicle Mechanisms: Solar panel deployment actuators, antenna positioning systems, and docking mechanism components for spacecraft applications

Why Choose Yicen Precision for Actuation Components?

Selecting the right manufacturing partner for actuation components CNC machining ensures system reliability and mission success. Yicen Precision brings specialized capabilities tailored to aerospace motion control requirements. Our rapid prototyping services support actuator development programs, delivering first-article components within 10-14 days for functional testing and hydraulic system integration validation.

We provide seamless prototype-to-production scalability, maintaining identical machining processes, surface finish procedures, and quality protocols that eliminate re-qualification delays and reduce program risk. Our engineering team delivers proactive DFM consultation, identifying sealing groove optimization, material selection guidance, and surface treatment recommendations during the design phase. Every actuation component includes complete material traceability with certified mill test reports, heat treatment documentation, surface finish verification, and dimensional inspection records satisfying AS9100D requirements.

Our cost-effective approach leverages efficient turning and boring strategies, optimized surface finishing processes, and strategic material sourcing to deliver competitive pricing for both prototype and production quantities. Yicen Precision understands that actuation components are critical to aircraft control authority and system reliability. Contact us today for engineering consultation and a detailed quote on your actuation components manufacturing requirements.