What are Airframe & Structural Parts?

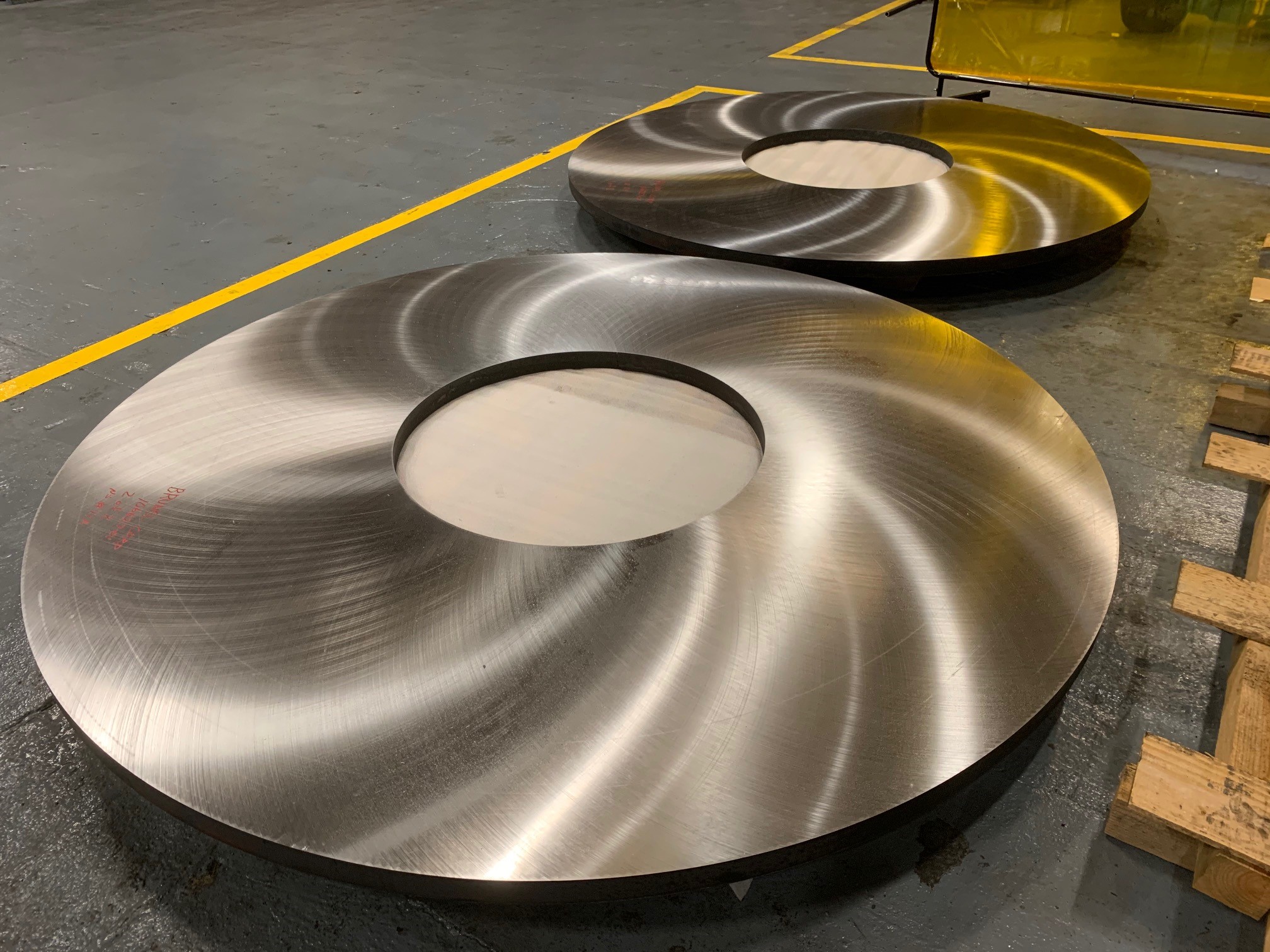

Airframe and structural parts encompass the load-bearing components that form the primary structure of aircraft, providing rigidity, support, and aerodynamic shape. These critical elements include fuselage frames, wing spars, ribs, stringers, bulkheads, longerons, keel beams, and structural fittings used throughout commercial aircraft, military jets, helicopters, and unmanned aerial systems. Each component transmits flight loads, supports secondary systems, and maintains aircraft structural integrity under extreme conditions. The precision and reliability of aerospace airframe structural parts directly influence aircraft performance, weight efficiency, and operational safety, making exacting manufacturing standards essential for airworthiness certification.

Key Technical Requirements

Manufacturing airframe structural parts demands precise dimensional control and material performance optimization. Typical tolerances range from ±0.005″ for general structural features to ±0.002″ for critical attachment points, bearing holes, and assembly interfaces. Material specifications require AMS-certified aerospace alloys including 7075-T6 aluminum (tensile strength 83 ksi), 2024-T3 aluminum for fatigue resistance, Ti-6Al-4V titanium for high-stress applications, and 4130 steel for heavy-duty fittings with complete mill certifications.

Surface finish requirements vary by application and assembly needs. Machined surfaces typically require Ra 125 microinches, while mating surfaces and seal interfaces demand Ra 63 microinches or smoother. Airframe parts must withstand complex stress distributions including bending moments, torsional loads, and shear forces during flight maneuvers. Components operate across temperature ranges from -65°F at altitude to +160°F on ground, resisting fatigue crack propagation throughout 30,000+ flight cycles. Edge break specifications and radius requirements prevent stress concentrations that could initiate structural failure.

Manufacturing Challenges & Solutions

Machining airframe structural parts presents unique manufacturing challenges requiring specialized expertise. Complex geometries including lightening pockets, tapered sections, and intricate rib patterns demand strategic material removal to achieve target weights. Thin-wall sections (often 0.060″-0.125″ thick) are prone to deflection and chatter during machining. Large part envelopes (wing spars exceeding 10 feet) require extensive machine travel and rigid fixturing.

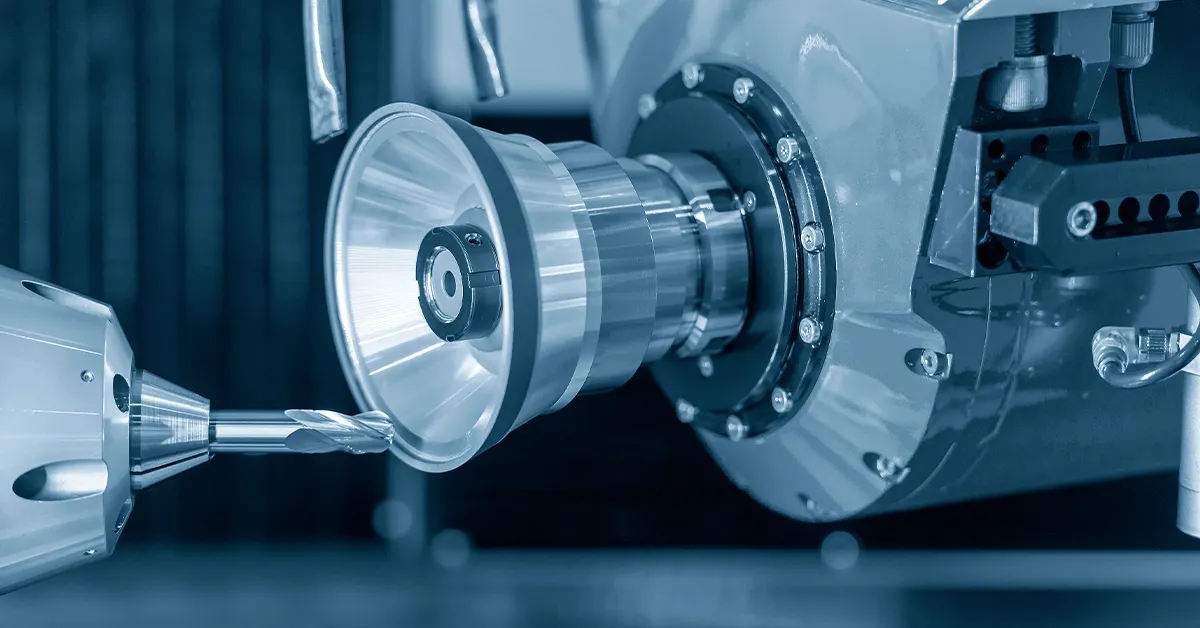

Yicen Precision overcomes these challenges through advanced process engineering. Our 5-axis CNC machining centers enable complete structural part processing in minimal setups, maintaining geometric relationships and reducing tolerance stack-up. Adaptive CAM programming calculates optimal toolpaths that balance material removal rates with part deflection, particularly critical for thin-wall aerospace structures. High-stiffness fixturing systems and vacuum workholding prevent part movement during aggressive milling operations.

Quality assurance protocols include first-article CMM inspection mapping all critical dimensions against CAD models. In-process verification using touch probes confirms feature locations before subsequent operations. We employ coordinate measuring machines (CMM) with 3D scanning capabilities for complex contoured surfaces. Every custom airframe component receives comprehensive dimensional reports, material certifications, and non-conformance documentation ensuring full compliance with engineering requirements and aerospace quality standards.

Applications & Use Cases

Precision-machined airframe and structural parts serve essential functions across diverse aerospace platforms:

- Commercial Aviation: Fuselage frames, wing ribs, and bulkheads for Boeing 737/777 and Airbus A320/A380 aircraft structures

- Military Fighter Aircraft: High-performance structural fittings, longerons, and wing spars for F-16, F-18, and stealth aircraft programs

- Regional & Business Jets: Structural brackets, keel beams, and empennage components for Embraer, Bombardier, and Gulfstream aircraft

- Rotorcraft Structures: Helicopter airframe components including cabin frames, tail boom structures, and rotor pylon mounts

- Unmanned Aerial Vehicles: Lightweight structural parts for tactical and surveillance UAV airframes requiring high strength-to-weight ratios

- Space Launch Vehicles: Structural adapters, payload fairings, and interstage components for satellite launch systems

- Aircraft Modification Programs: Custom structural reinforcements, repair doublers, and retrofit brackets for fleet upgrades and STC modifications

Why Choose Yicen Precision for Airframe & Structural Parts?

Selecting the right manufacturing partner for airframe structural parts CNC machining ensures program success and certification compliance. Yicen Precision brings specialized capabilities tailored to aerospace structural requirements. Our rapid prototyping services accelerate design validation cycles, delivering first articles within 7-14 days to support structural testing and engineering analysis.

We provide complete prototype-to-production scalability, maintaining identical machining strategies, tooling setups, and quality protocols that eliminate re-qualification delays and reduce program risk. Our engineering team delivers proactive DFM consultation, identifying potential manufacturing issues, weight optimization opportunities, and cost reduction strategies before production begins. Every airframe structural part includes complete material traceability with certified mill test reports, chemical composition analysis, and mechanical property documentation satisfying AS9100D and customer quality requirements.

Our approach balances cost-efficiency with uncompromising quality through optimized nesting strategies, efficient toolpaths, and material yield maximization. Yicen Precision understands that airframe components directly impact aircraft structural integrity and passenger safety. Contact us today for engineering consultation and a detailed quote on your airframe and structural parts manufacturing requirements.