What are Brackets & Mounts?

Brackets and mounts are structural attachment components that secure equipment, systems, and assemblies to aircraft structures while providing load transfer, vibration isolation, and precise positioning. These essential elements include equipment mounting brackets, engine support mounts, avionics rack brackets, control surface hinges, sensor mounts, cable support brackets, and structural reinforcement brackets used throughout commercial aircraft, military jets, helicopters, unmanned aerial vehicles, and spacecraft. Each aerospace bracket and mount must withstand static loads, dynamic forces, vibration environments, and thermal cycling while maintaining dimensional stability. The reliability of custom brackets and mounts directly impacts equipment security, system alignment, and structural integrity across all aircraft operations.

Key Technical Requirements

Manufacturing brackets and mounts demands precision engineering and structural optimization. Typical tolerances range from ±0.005″ for general bracket geometry to ±0.002″ for mounting hole locations, bearing surfaces, and critical interface dimensions that ensure proper alignment and load distribution. Material specifications require aerospace-grade alloys including 7075-T6 aluminum (ultimate tensile strength 83 ksi), 2024-T3 aluminum for fatigue applications, Ti-6Al-4V titanium (tensile strength 130 ksi), 17-4PH stainless steel (condition H1150), and 4130 chromoly steel with complete material certifications.

Surface finish requirements vary by functional area. Machined surfaces typically require Ra 125 microinches, while bearing surfaces and sliding interfaces demand Ra 63 microinches or smoother to minimize wear. Precision brackets and mounts must withstand static loads ranging from 50 to 5,000 pounds depending on application, vibration environments meeting MIL-STD-810 specifications (10-2000 Hz), shock loads during hard landings or combat maneuvers, and thermal cycling from -65°F to +200°F. Components require proper edge breaks to prevent stress concentrations, corrosion-resistant surface treatments for environmental protection, and weight optimization through topology design while maintaining structural factors of safety exceeding 1.5 for ultimate loads.

Manufacturing Challenges & Solutions

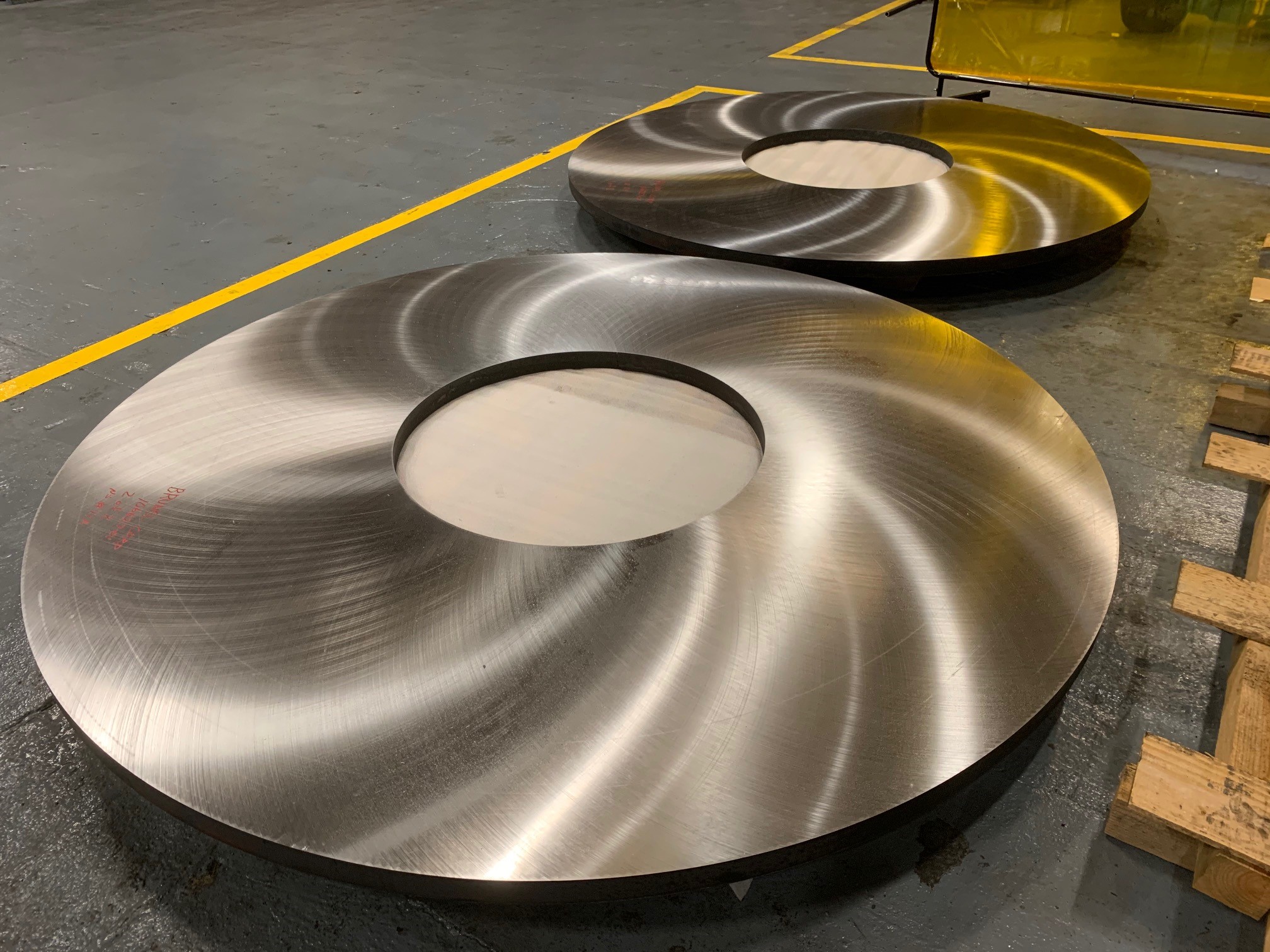

Machining brackets and mounts presents diverse technical challenges requiring flexible manufacturing capabilities. Complex geometries including angled mounting surfaces, lightening pockets, gussets, integrated hinges, and multi-plane interfaces demand strategic setup planning. Thin-wall sections and intricate rib structures are prone to deflection during machining operations. Material variety from soft aluminum to hardened stainless steel requires adaptive cutting strategies.

Yicen Precision overcomes these challenges through advanced manufacturing approaches and equipment versatility. Our 5-axis CNC machining centers enable complete bracket processing including compound angles, multiple mounting surfaces, and integrated features in single setups, maintaining geometric relationships and hole pattern accuracy. Adaptive CAM programming optimizes roughing and finishing operations based on material properties, feature geometry, and wall thickness to prevent deflection. Strategic workholding and vacuum fixturing systems secure parts during multi-sided machining operations.

Quality control protocols ensure brackets and mounts meet all structural and interface requirements. First-article CMM inspection verifies all critical dimensions including mounting hole patterns (typically within ±0.001″ positional tolerance), surface angles, and interface flatness. Hardness testing confirms proper material heat treatment conditions for strength requirements. We perform dimensional verification of load-bearing features and clearance dimensions ensuring proper equipment fit. Every custom bracket and mount receives comprehensive dimensional reports, material certifications, first-article inspection documentation, and surface treatment records ensuring complete compliance with aerospace structural standards.

Applications & Use Cases

Precision-machined brackets and mounts serve essential mounting functions across diverse aerospace platforms:

- Commercial Aircraft Systems: Avionics equipment racks, overhead bin support brackets, seat track mounts, and galley equipment brackets for Boeing and Airbus aircraft

- Military Fighter Aircraft: Weapons pylon mounts, radar equipment brackets, mission computer mounts, and ejection seat support structures for tactical aircraft

- Helicopter Systems: Engine mount assemblies, transmission support brackets, rotor head mounts, and mission equipment mounting for military and commercial rotorcraft

- Engine Installations: Powerplant mounting brackets, nacelle support structures, engine accessory mounts, and exhaust system hangers for jet and turboprop engines

- Landing Gear Assemblies: Actuator mounting brackets, door support hinges, gear retraction mechanism mounts, and brake assembly brackets

- UAV/Drone Systems: Payload mounting brackets, sensor gimbal mounts, battery tray supports, and flight controller brackets for unmanned aerial vehicles

- Spacecraft Applications: Equipment mounting brackets, solar panel support structures, instrument mounts, and structural reinforcement brackets for satellites and launch vehicles

Why Choose Yicen Precision for Brackets & Mounts?

Selecting the right manufacturing partner for brackets mounts CNC machining ensures reliable equipment installation and structural integrity. Yicen Precision brings specialized capabilities tailored to aerospace mounting component requirements. Our rapid prototyping services accelerate equipment integration programs, delivering first-article brackets within 5-7 days for fit-check validation and load testing.

We provide seamless prototype-to-production scalability, maintaining identical machining processes, fixture designs, and quality protocols that eliminate re-qualification delays and reduce integration risk. Our engineering team delivers proactive DFM consultation, identifying weight reduction opportunities, stress concentration mitigation, and manufacturability improvements during the design phase. Every bracket and mount includes complete material traceability with certified mill test reports, heat treatment certifications when applicable, and dimensional inspection documentation satisfying AS9100D requirements.

Our cost-effective approach leverages efficient material nesting, optimized toolpaths, and batch processing strategies to deliver competitive pricing for both custom one-off brackets and production quantities. Yicen Precision understands that brackets and mounts are critical to equipment security and aircraft structural integrity. Contact us today for engineering consultation and a detailed quote on your brackets and mounts manufacturing requirements.