What Are Engine Components?

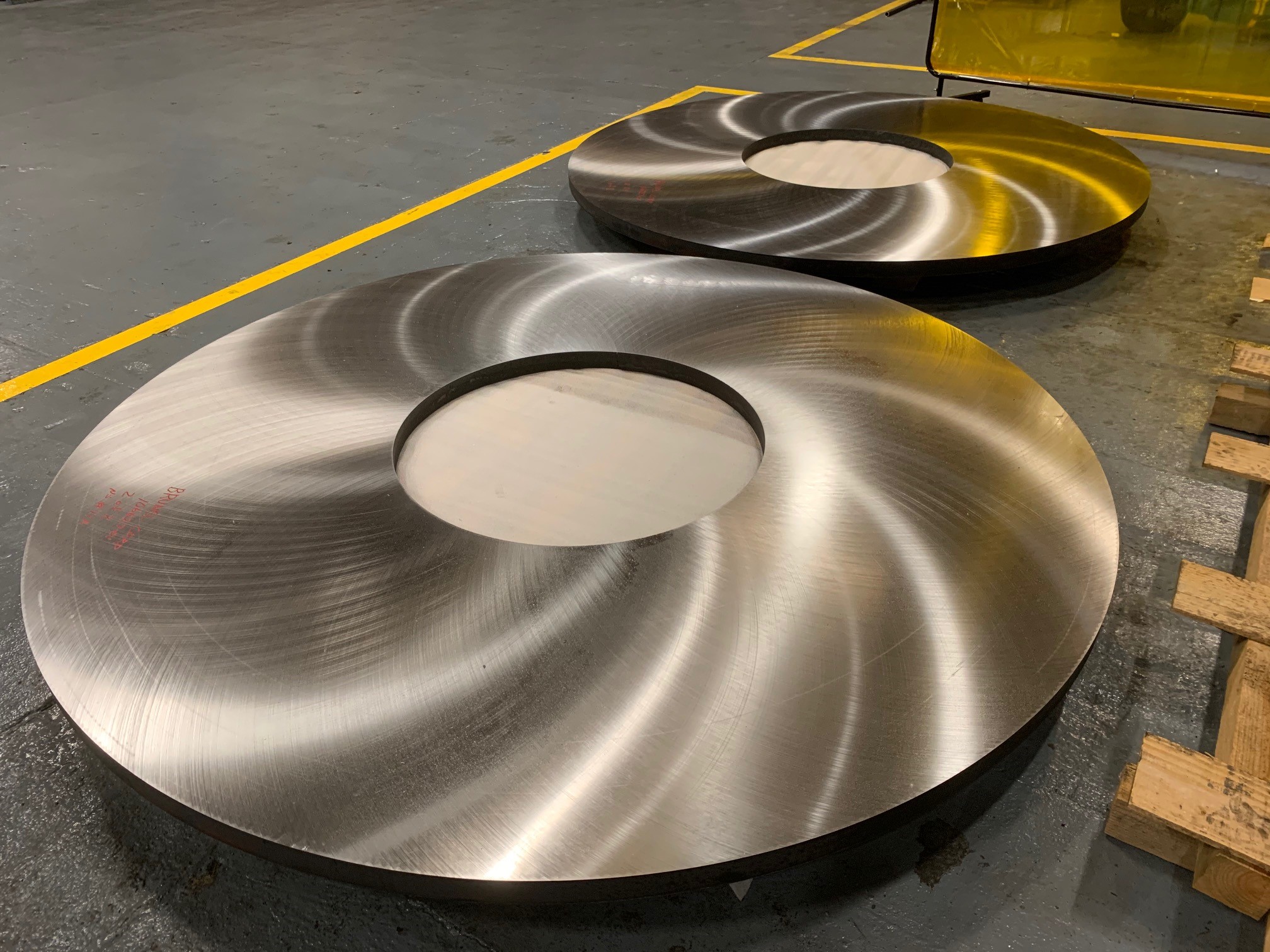

Engine components encompass the critical precision parts that enable jet propulsion, turbine operation, and power generation in aerospace applications. These engineered elements include turbine discs, compressor sections, combustion liners, nozzle assemblies, bearing housings, and fuel delivery systems used in commercial aircraft engines, military jet powerplants, auxiliary power units (APUs), and spacecraft propulsion mechanisms. Each component plays a vital role in converting fuel into thrust while enduring extreme thermal cycling, rotational forces, and corrosive environments. The reliability of aerospace engine components directly impacts flight safety, fuel efficiency, and operational performance across all aviation platforms.

Key Technical Requirements

Manufacturing precision engine components demands adherence to exceptionally tight specifications. Typical tolerance requirements range from ±0.001″ for standard features down to ±0.0005″ or tighter for critical mating surfaces and aerodynamic profiles. Material specifications must meet AMS (Aerospace Material Specifications) standards with complete mill certification and lot traceability for nickel-based superalloys, titanium alloys, and precipitation-hardened stainless steels.

Surface finish requirements vary by function. Combustion-facing surfaces often require Ra 32 microinches or smoother to minimize heat retention. Engine components must withstand extreme stress concentrations, including cyclic loading, thermal shock, and vibration frequencies exceeding 20,000 Hz. Temperature resistance is paramount—hot-section components regularly operate between 1,200°F and 1,800°F while maintaining dimensional stability. Components must also resist oxidation, sulfidation, and corrosive attack from combustion byproducts throughout thousands of flight cycles.

Manufacturing Challenges & Solutions

Machining engine components presents unique challenges requiring specialized expertise. Complex geometries including internal cooling passages, compound curves, and thin-wall sections (often less than 0.040″ thick) demand exceptional tool control. The inherent hardness of superalloys like Inconel 625 and Waspaloy creates rapid tool wear during cutting operations.

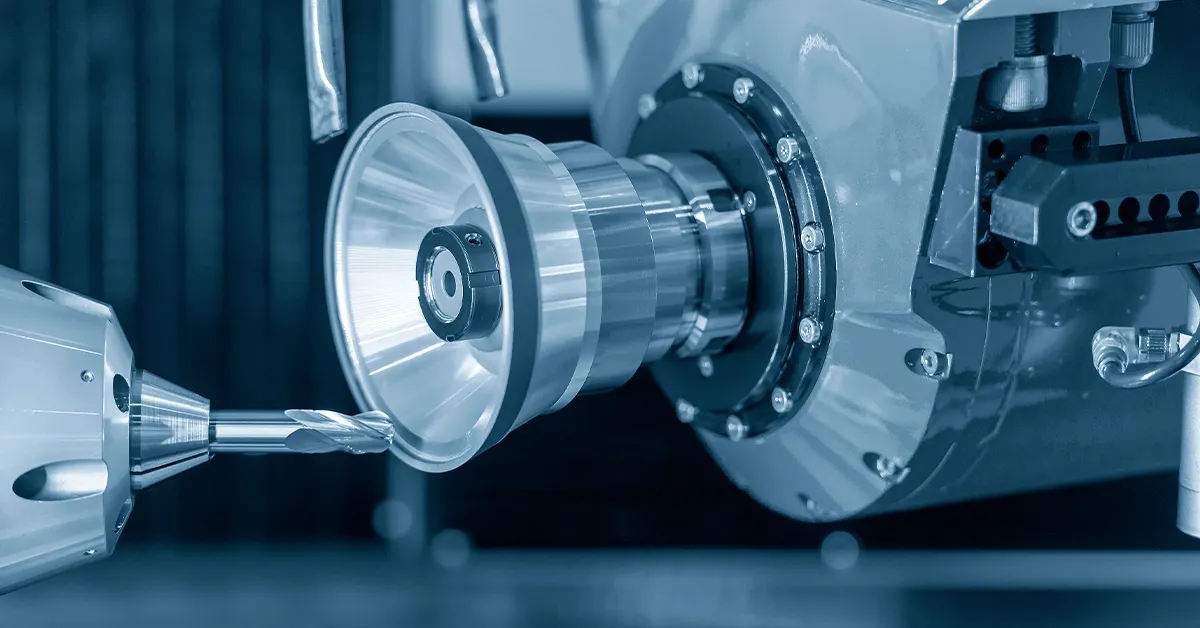

Yicen Precision overcomes these challenges through advanced technology deployment. Our 5-axis CNC machining centers enable complete part processing in single setups, eliminating tolerance stack-up while maintaining geometric relationships. Advanced CAM software with adaptive toolpath strategies optimizes chip evacuation and manages cutting forces on delicate features. High-pressure coolant systems and specialized carbide tooling extend tool life while protecting part integrity.

Quality control includes in-process probing for real-time dimensional verification, first-article inspection protocols, and final CMM dimensional reports comparing measurements against CAD models. We employ non-destructive testing including fluorescent penetrant inspection (FPI) for surface crack detection. Each part receives material certification documentation and dimensional inspection reports, ensuring complete compliance with aerospace standards.

Applications & Use Cases

Precision-machined engine components serve critical functions across diverse aerospace platforms:

- Commercial Aviation Engines: Turbine housings, compressor blades, and fuel nozzles for Boeing and Airbus propulsion systems

- Military Fighter Jets: Afterburner components, turbine discs, and thrust vectoring elements for high-performance tactical aircraft

- Helicopter Powerplants: Transmission housings, drive shaft components, and governor assemblies for rotorcraft propulsion

- Auxiliary Power Units (APUs): Starter generators, turbine wheels, and exhaust manifolds for onboard power systems

- Space Launch Vehicles: Rocket engine injectors, combustion chamber liners, and nozzle throat sections

- Unmanned Aerial Systems (UAS): Micro-turbine components and compact engine housings for long-endurance drones

- Ground Support Equipment: Mobile power unit components and test stand fixtures for engine maintenance operations

Why Choose Yicen Precision for Engine Components?

Selecting the right manufacturing partner for engine components CNC machining determines program success. Yicen Precision brings specialized advantages that benefit your engine development requirements. Our rapid prototyping capabilities accelerate design validation cycles, delivering first articles in days to keep certification programs on schedule.

We provide seamless scalability from prototype to production, maintaining identical process parameters to eliminate re-qualification delays. Our engineering team offers proactive DFM consultation, identifying manufacturability issues before they impact cost or schedule. Every aerospace engine component includes complete material traceability with mill certificates, heat lot numbers, and test reports satisfying stringent audit requirements.

Cost-effectiveness drives our approach without compromising quality. We optimize toolpaths, minimize material waste, and leverage volume purchasing of aerospace-grade alloys to deliver competitive pricing. When you partner with Yicen Precision, you gain a committed extension of your engineering team focused on delivering engine components that perform flawlessly. Contact us today for technical consultation on your engine component requirements.