What is Landing Gear Hardware?

Landing gear hardware encompasses the structural and mechanical components that support aircraft weight during ground operations, takeoff, and landing. These critical parts include main strut assemblies, shock absorber cylinders, actuator housings, drag braces, side struts, torque links, trunnion mounts, and retraction mechanisms used across commercial airliners, military aircraft, business jets, and helicopters. Each component must withstand repetitive high-impact loads, absorb landing shock, and operate reliably through thousands of flight cycles. The integrity of aerospace landing gear hardware directly affects aircraft safety, operational readiness, and maintenance intervals, making precision manufacturing non-negotiable.

Key Technical Requirements

Manufacturing landing gear hardware demands exceptional dimensional accuracy and material performance. Typical tolerances range from ±0.002″ for general features to ±0.0005″ for bearing surfaces, pivot pins, and actuator bores. Material specifications require AMS-certified high-strength alloys including 4340 alloy steel (heat-treated to 260-280 ksi), 300M ultra-high-strength steel, titanium Ti-6Al-4V, and 7075-T6 aluminum with full mill certifications.

Surface finish requirements are critical for fatigue life. Bearing surfaces typically require Ra 16-32 microinches, while hydraulic sealing surfaces demand Ra 8 microinches or smoother. Landing gear hardware must withstand extreme stress concentrations—shock loads exceeding 6G forces during hard landings, cyclic fatigue stresses, and corrosion from hydraulic fluids and environmental exposure. Components must maintain structural integrity across temperature ranges from -65°F to +160°F while resisting stress corrosion cracking and hydrogen embrittlement throughout their service life.

Manufacturing Challenges & Solutions

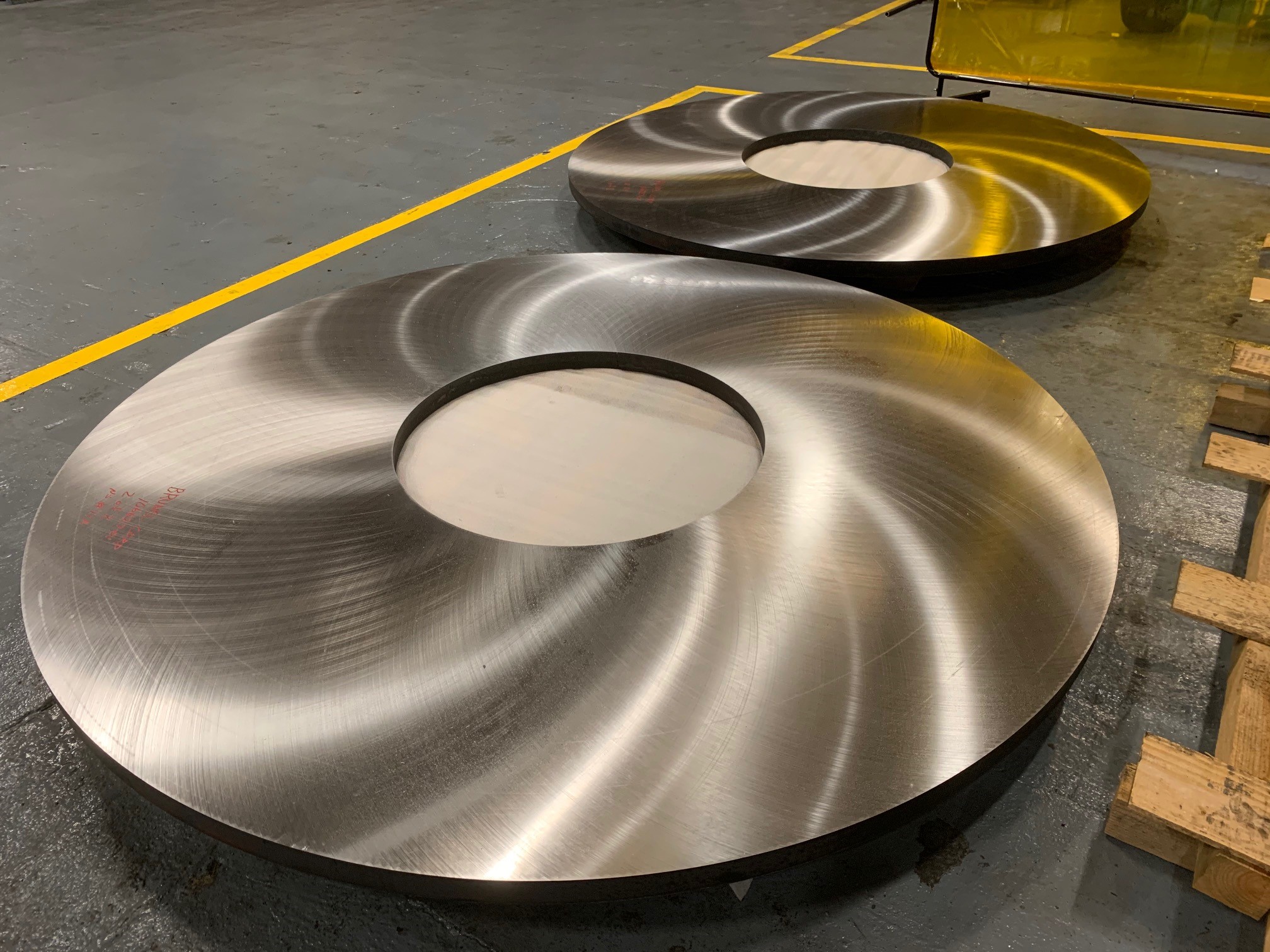

Machining landing gear hardware presents significant technical challenges. Complex geometries including deep bores, internal passages, and wall thickness transitions require rigid setups and vibration control. High-strength steels and titanium alloys generate extreme cutting forces and rapid tool wear. Large part sizes (strut cylinders often exceed 36″ length) demand stable fixturing and thermal management.

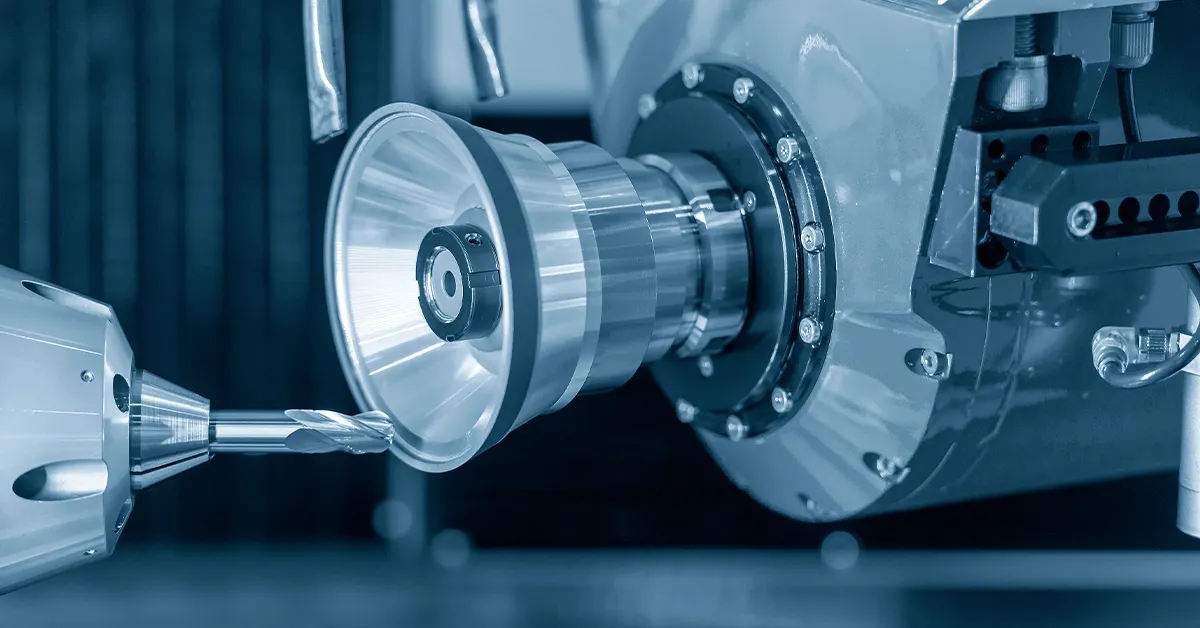

Yicen Precision addresses these challenges through specialized manufacturing strategies. Our 5-axis CNC machining centers with high-torque spindles handle deep-cavity machining and compound angles in single setups, ensuring geometric accuracy. Advanced CAM programming optimizes toolpaths for chip evacuation in deep-hole drilling and boring operations. We utilize carbide and ceramic insert tooling specifically designed for hardened steels and titanium.

Quality control protocols include first-article CMM inspection verifying all critical dimensions against engineering drawings. In-process gauging monitors bore concentricity and straightness during machining. Final inspection includes magnetic particle inspection (MPI) or fluorescent penetrant inspection (FPI) to detect surface discontinuities. Every custom landing gear hardware component receives dimensional reports, material certifications, and heat treatment documentation ensuring full traceability.

Applications & Use Cases

Precision-machined landing gear hardware serves critical functions across aerospace platforms:

- Commercial Aviation: Main landing gear struts, nose gear assemblies, and actuator housings for Boeing 737/787 and Airbus A320/A350 aircraft

- Military Fighter Jets: High-performance landing gear components for F-16, F-35, and tactical aircraft requiring carrier-based operations

- Business Aviation: Landing gear hardware for Gulfstream, Bombardier, and Cessna Citation series jets

- Rotorcraft Systems: Helicopter landing gear struts, shock absorbers, and skid assemblies for military and commercial helicopters

- Cargo Aircraft: Heavy-duty landing gear components for C-130, C-17, and freight transport aircraft

- UAV/Drone Systems: Landing gear assemblies for large unmanned aerial vehicles requiring autonomous landing capabilities

- Retrofit & MRO Programs: Replacement landing gear hardware for aging aircraft fleets and overhaul maintenance operations

Why Choose Yicen Precision for Landing Gear Hardware?

Selecting a qualified manufacturer for landing gear hardware CNC machining is crucial for aircraft safety and certification. Yicen Precision delivers specialized advantages for landing gear components. Our rapid prototyping services support new aircraft development programs, delivering first articles within 10-14 days for design validation and structural testing.

We provide seamless prototype-to-production scalability, preserving process documentation, fixturing strategies, and inspection protocols that eliminate costly re-qualification. Our engineering team offers comprehensive DFM consultation, identifying stress concentrations, machining challenges, and design optimizations before production begins. Every landing gear hardware component includes complete material traceability with certified mill test reports, heat treatment certificates, and dimensional inspection documentation satisfying AS9100 and FAA requirements.

Our cost-effective approach leverages efficient toolpaths, optimized material utilization, and strategic alloy sourcing to deliver competitive pricing without compromising structural integrity. Yicen Precision operates with a quality-first mindset, understanding that landing gear hardware directly impacts passenger safety. Contact us today for technical consultation and a custom quote on your landing gear hardware requirements.