What are Thermal Barriers & Heat Shields?

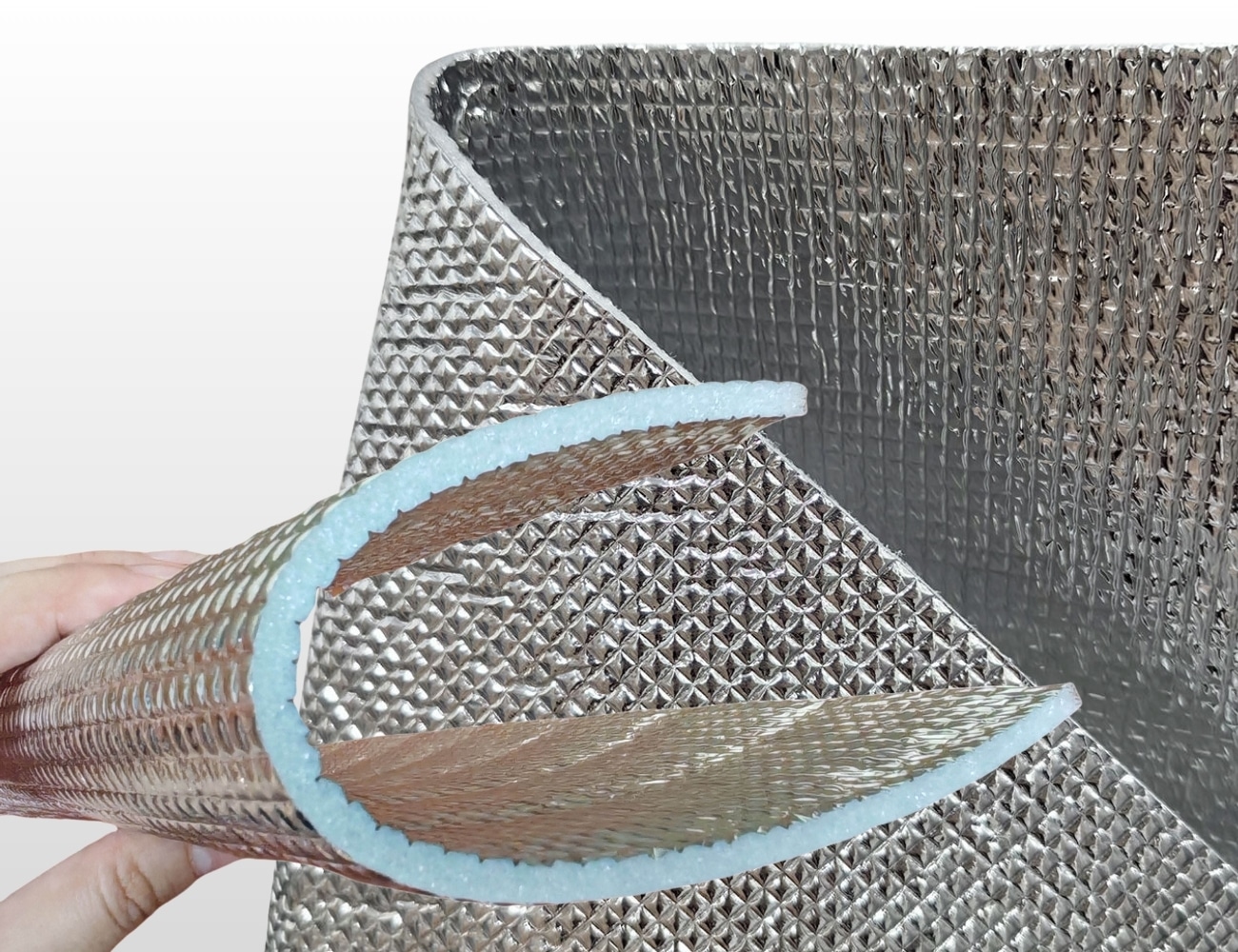

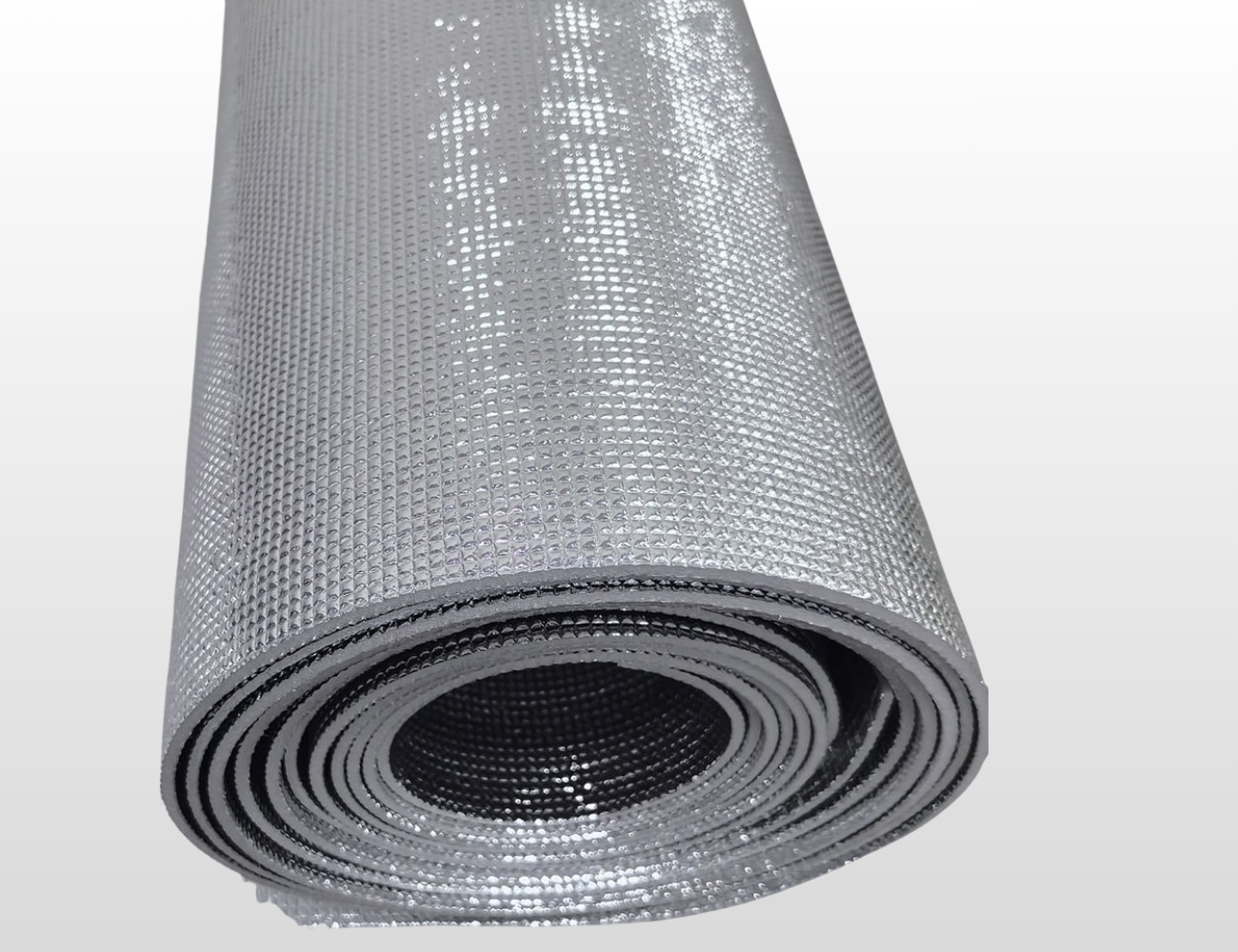

Thermal barriers and heat shields are specialized protective components designed to prevent heat transfer from high-temperature sources to temperature-sensitive aircraft systems and structures. These critical elements include engine firewalls, exhaust heat shields, turbine insulation panels, nacelle thermal barriers, and re-entry vehicle heat shields used throughout commercial aircraft, military jets, helicopters, spacecraft, and rocket propulsion systems. Each thermal protection component must resist extreme temperatures, thermal cycling, oxidation, and thermal shock while maintaining structural integrity. The performance of aerospace thermal barriers directly impacts system reliability, component longevity, and operational safety across all flight regimes.

Key Technical Requirements

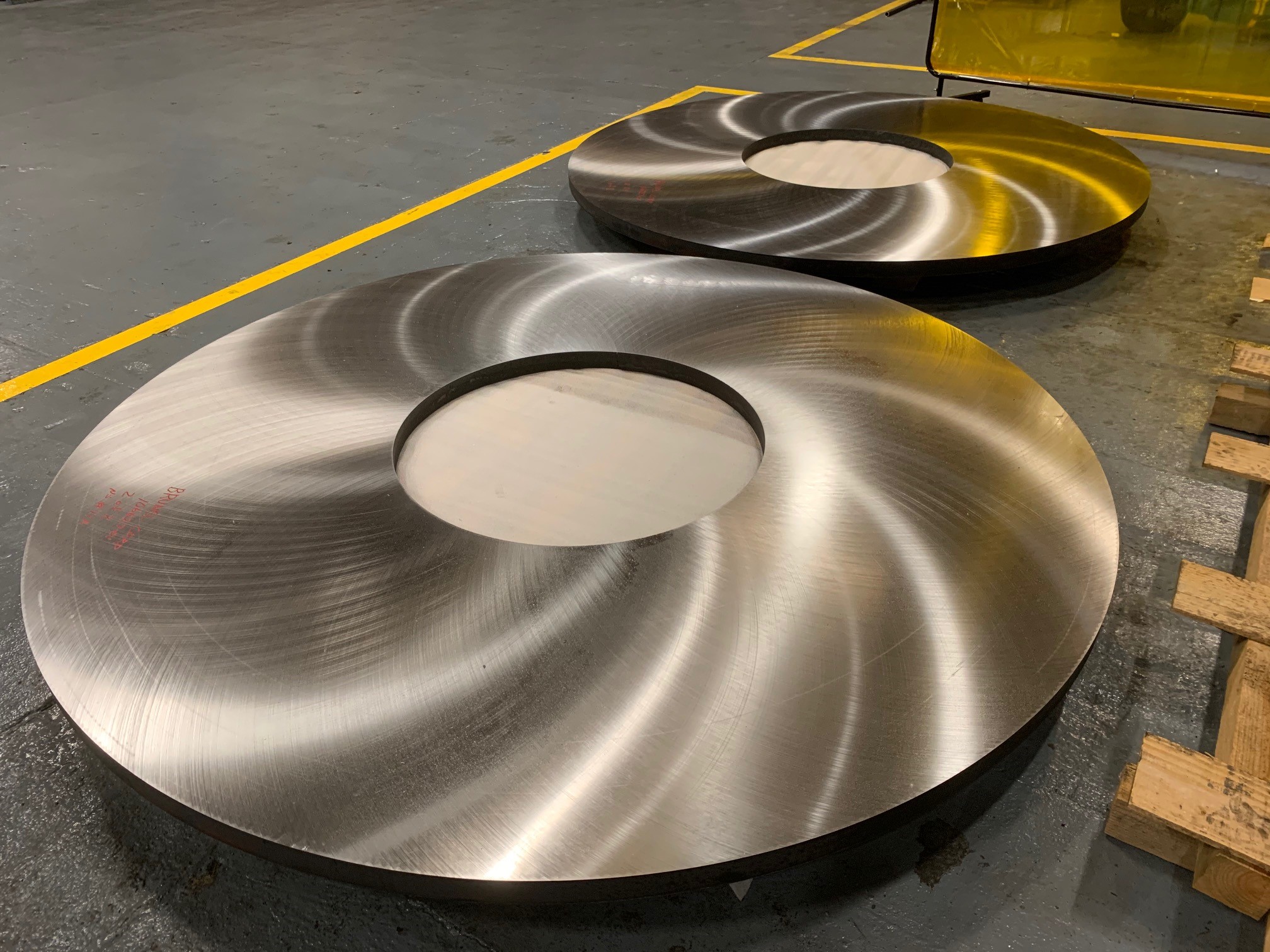

Manufacturing thermal barriers and heat shields demands specialized material selection and precision engineering. Typical tolerances range from ±0.010″ for general shield geometry to ±0.003″ for mounting hole locations and interface surfaces that ensure proper fitment and thermal gaps. Material specifications require heat-resistant alloys including Inconel 625 (service temperature 1,800°F), Inconel 718, titanium alloys for moderate temperatures (900°F), 321 stainless steel with titanium stabilization, and 347 stainless steel for oxidation resistance with complete material certifications.

Surface finish requirements balance functionality with thermal performance. Machined surfaces typically require Ra 125 microinches, while reflective heat shield surfaces benefit from polished finishes (Ra 32 microinches) to maximize thermal radiation reflection. Precision thermal barriers must withstand operating temperatures from 1,200°F to 2,500°F depending on application, thermal cycling gradients exceeding 500°F per minute, and oxidation environments from combustion products. Components require thermal expansion coefficients matching adjacent structures to prevent warping, thermal fatigue resistance through thousands of heat cycles, and low thermal conductivity to minimize heat transfer. Many applications demand thermal barrier coatings (TBC) with ceramic top layers providing additional insulation.

Manufacturing Challenges & Solutions

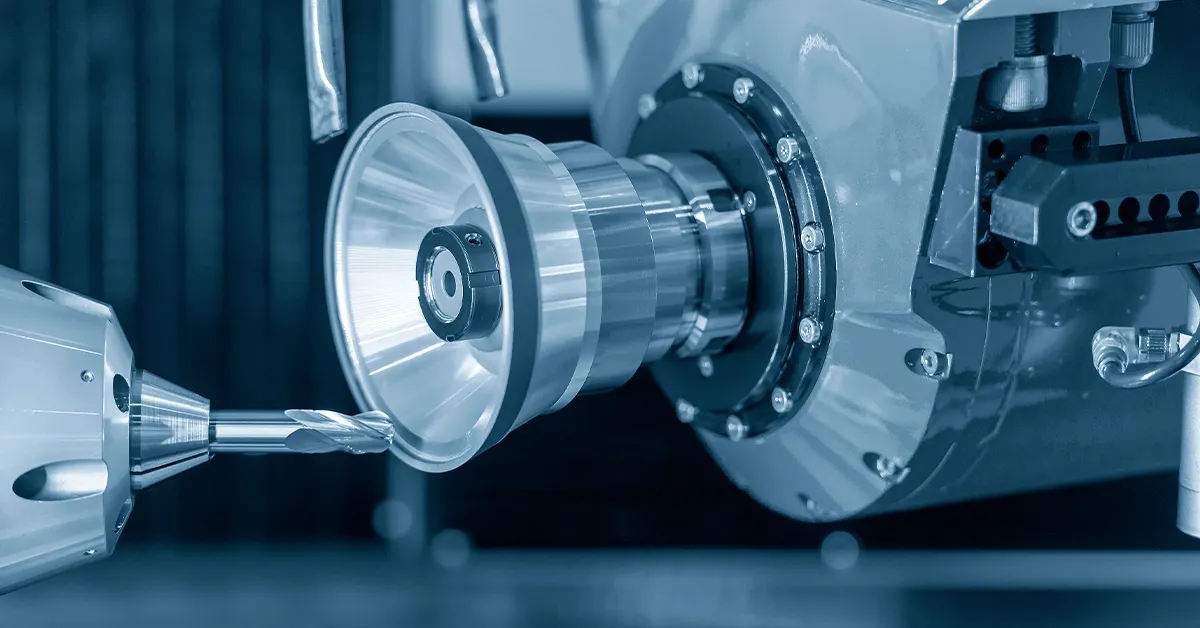

Machining thermal barriers and heat shields presents unique technical challenges requiring specialized manufacturing expertise. Complex geometries including formed contours, ventilation louvers, standoff features, and multi-layer assemblies demand strategic programming approaches. Heat-resistant alloys like Inconel exhibit extreme work hardening and generate high cutting forces during machining operations. Large shield panels with thin cross-sections are susceptible to thermal distortion and residual stress.

Yicen Precision overcomes these challenges through advanced manufacturing strategies and process optimization. Our 5-axis CNC machining centers enable efficient processing of contoured heat shields and thermal panels in minimal setups, maintaining geometric accuracy across complex shapes. Advanced CAM programming with specialized toolpath strategies manages chip load and cutting temperatures when machining nickel-based superalloys and heat-resistant stainless steels. We utilize carbide and ceramic tooling specifically designed for high-temperature alloys, combined with optimized cutting parameters.

Quality control protocols ensure thermal protection components meet all performance requirements. First-article CMM inspection verifies all critical dimensions including mounting locations, thermal gap clearances, and contour profiles. Flatness measurement confirms panels meet warpage specifications critical for proper installation and thermal performance. We perform material verification through positive material identification (PMI) to ensure correct alloy selection. Every custom thermal barrier receives comprehensive dimensional reports, material certifications, heat treatment documentation, and coating specifications ensuring complete compliance with aerospace thermal management standards.

Applications & Use Cases

Precision-machined thermal barriers and heat shields protect critical systems across diverse aerospace platforms:

- Commercial Aircraft Engines: Nacelle heat shields, exhaust cone thermal barriers, and APU firewalls for Boeing 737/787 and Airbus A320/A350 aircraft

- Military Fighter Jets: Afterburner heat shields, engine bay thermal barriers, and exhaust system insulation for F-16, F-18, and stealth aircraft programs

- Helicopter Powerplants: Turbine exhaust shields, transmission heat barriers, and engine compartment firewalls for military and commercial rotorcraft

- Space Re-Entry Vehicles: Ablative heat shield substrates, thermal protection panels, and heat sink structures for spacecraft and launch vehicle applications

- Rocket Propulsion Systems: Thrust chamber heat shields, nozzle thermal barriers, and combustion chamber insulation for orbital and sub-orbital vehicles

- Auxiliary Power Units: APU exhaust heat shields, compartment firewalls, and thermal insulation panels for aircraft auxiliary systems

- Ground Test Equipment: Engine test cell heat shields, thermal barriers for propulsion test stands, and high-temperature fixture components

Why Choose Yicen Precision for Thermal Barriers & Heat Shields?

Selecting the right manufacturing partner for thermal barriers heat shields CNC machining ensures thermal management success and system protection. Yicen Precision brings specialized capabilities tailored to high-temperature aerospace applications. Our rapid prototyping services support thermal protection development programs, delivering first-article components within 10-14 days for fit-check validation and thermal testing.

We provide seamless prototype-to-production scalability, maintaining identical machining processes, material handling procedures, and quality protocols that eliminate re-qualification delays. Our engineering team delivers proactive DFM consultation, identifying thermal expansion management strategies, weight optimization opportunities, and coating compatibility during the design phase. Every thermal barrier and heat shield includes complete material traceability with certified mill test reports, chemical composition analysis, and mechanical property documentation satisfying AS9100D requirements.

Our cost-effective approach leverages efficient nesting strategies for sheet materials, optimized toolpaths for heat-resistant alloys, and strategic material sourcing to deliver competitive pricing. Yicen Precision understands that thermal protection components are critical to system longevity and operational safety. Contact us today for engineering consultation and a detailed quote on your thermal barriers and heat shields manufacturing requirements.