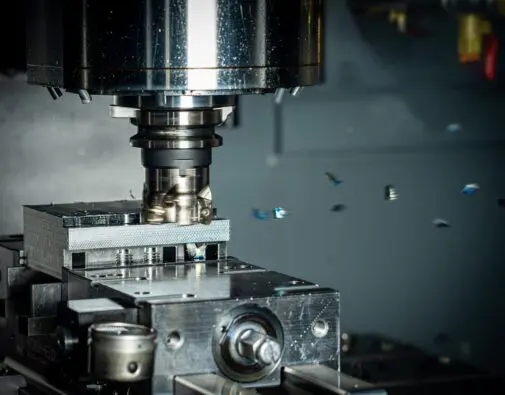

The automotive industry demands more than just high output it demands accuracy, repeatability, and adaptability across a variety of materials and geometries. CNC machining checks all these boxes, enabling the precise production of components that directly impact vehicle safety, reliability, and efficiency.

At Yicen Precision, CNC isn’t just a process it’s a promise of consistency, attention to detail, and engineering excellence tailored to automotive applications.

Core Benefits of CNC for Automotive Parts:

- Tight tolerances that ensure compatibility and performance

- Consistent part quality for production volumes big or small

- Support for diverse materials like aluminum, titanium, steel, and polymers

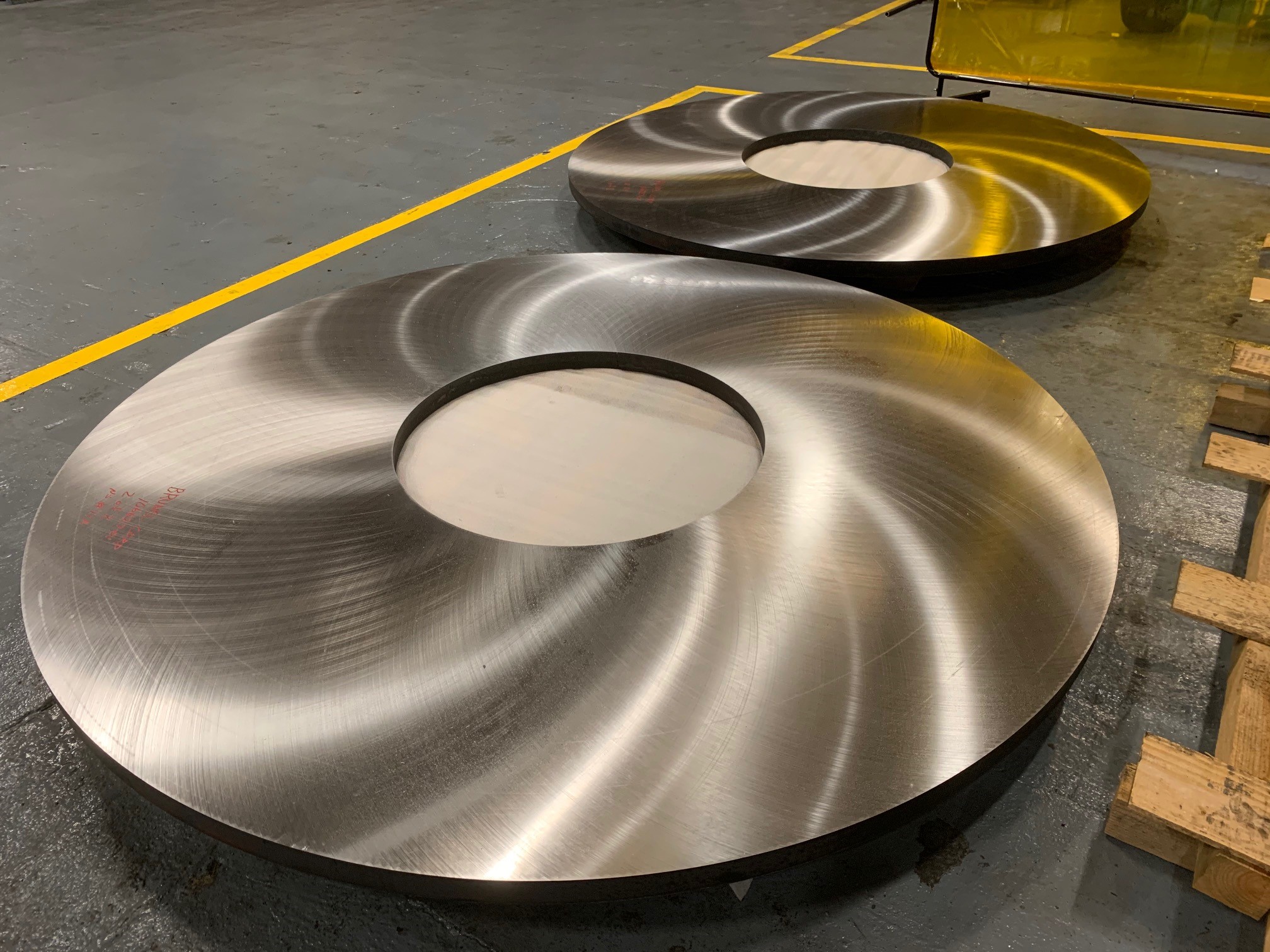

- Complex geometries achievable through multi-axis machining

- Flexible prototyping and production capabilities under one roof

End-to-End CNC Solutions for Automotive Innovation

Every vehicle is a system of interdependent parts and we machine many of the ones that matter most. Yicen Precision works across every stage of automotive development, from R&D to large-scale production, offering responsive, high-precision solutions.

High-Precision Custom Automotive Parts

Whether you’re engineering a next-gen EV or fine-tuning a performance package, off-the-shelf components often fall short. That’s why we specialize in custom parts that match your exact specs.

Common applications include:

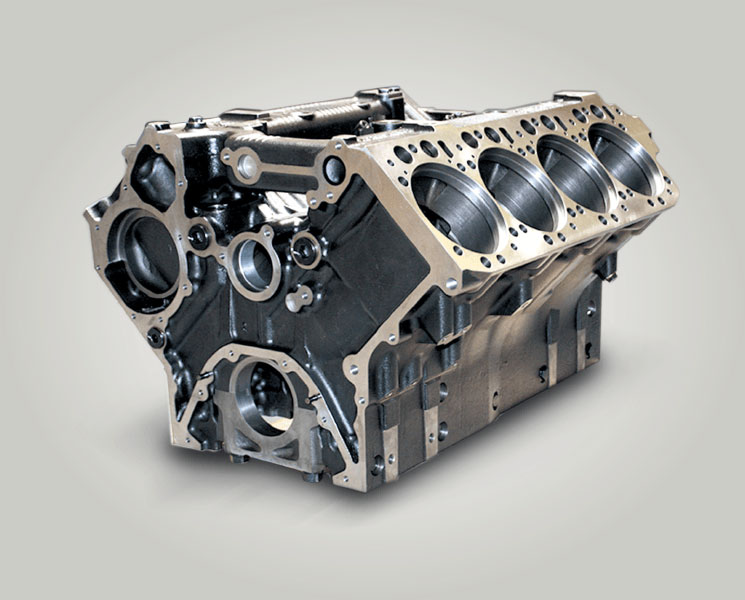

- Cylinder heads, brackets, and cam covers

- Suspension arms and linkages

- Transmission cases and drivetrain shafts

- Brake caliper mounts and pedal components

- Sensor housings and custom control enclosures

- Aftermarket upgrades for motorsport or luxury builds

Our combination of CNC milling, turning, Wire EDM, and surface finishing enables us to deliver automotive parts that meet both structural and cosmetic demands.

Accelerating Automotive R&D with Fast CNC Prototyping

In the automotive sector, speed to validation is critical. Yicen Precision supports rapid development with quick-turn CNC prototypes, helping engineers test fit, form, and function early in the product cycle.

Prototype applications include:

- EV battery trays and cooling plates

- Lightweight aluminum brackets and housings

- Engine airflow or exhaust system mockups

- Mounting and interface hardware for sensors or actuators

With in-house DFM guidance and machining expertise, we reduce design complexity and help you iterate quickly without compromising quality.

CNC Production Machining at Scale

When you’re ready to scale, Yicen Precision is ready to deliver. We offer dependable production machining backed by robust quality controls and repeatable setups. Whether it’s 250 brake brackets or 10,000 electric motor flanges, we help you meet demand on time and within spec.

Production capabilities include:

- 3- and 5-axis milling for precision surfaces and cutouts

- CNC turning for shafts, bushings, and symmetrical parts

- Multi-part machining strategies to minimize downtime

- Automated inspection and serialized tracking for QC

Reverse Engineering Bridging the Gap Between Past and Present

Automotive innovation doesn’t always mean starting from scratch. For legacy systems, discontinued components, or aftermarket projects, Yicen Precision offers reverse engineering services to recreate hard-to-source parts with modern precision.

Ideal for:

- Classic and vintage car restorations

- Custom tuning and performance enhancements

- Fleet maintenance for commercial or industrial vehicles

- Low-volume production for rare or obsolete parts

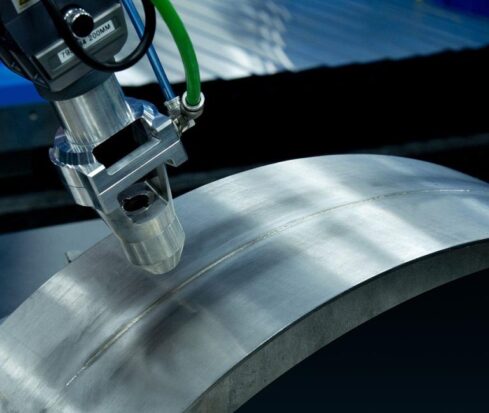

Using 3D scanning and CAD modeling, we rebuild accurate digital replicas and produce functional replacements often with better durability than the originals.

Meeting the Stringent Demands of Automotive Manufacturing

When the road is unforgiving, the parts must be flawless. That’s why Yicen Precision invests in strict quality assurance processes that align with automotive-grade expectations.

Our QC measures include:

- First article inspections (FAI)

- Coordinate Measuring Machine (CMM) reports

- In-process and final part inspections

- Full material traceability and certifications

- ISO-compliant documentation packages

We take pride in delivering parts that not only meet tolerance but exceed expectations.

Why Automotive Clients Trust Yicen Precision

From startups developing EV platforms to global OEMs refining combustion platforms, Yicen Precision is a proven partner for precision components. Here’s why we’re trusted in the fast-moving automotive world:

Speed & Flexibility

Short lead times, fast turnarounds, and the ability to pivot quickly especially in early-stage design or sudden production needs.

Engineering Collaboration

Our experienced engineers offer DFM support, CAD file optimization, and material guidance to ensure your parts are both functional and cost-effective.

Scalable Capacity

Start small and scale big our production systems are built to grow with your project, whether you need 50 parts or 50,000.

Advanced Machining Capabilities

We support complex projects with advanced services like 5-axis CNC, Wire EDM, deep-hole drilling, and multi-surface finishing.

Power Your Next Automotive Project with Yicen Precision

The road ahead demands better parts smarter, lighter, faster, and stronger. Yicen Precision delivers the precision you need to move forward with confidence. Whether you’re reinventing transportation or refining a proven design, our CNC solutions are ready to help you drive innovation.

Let’s build the future of mobility together.