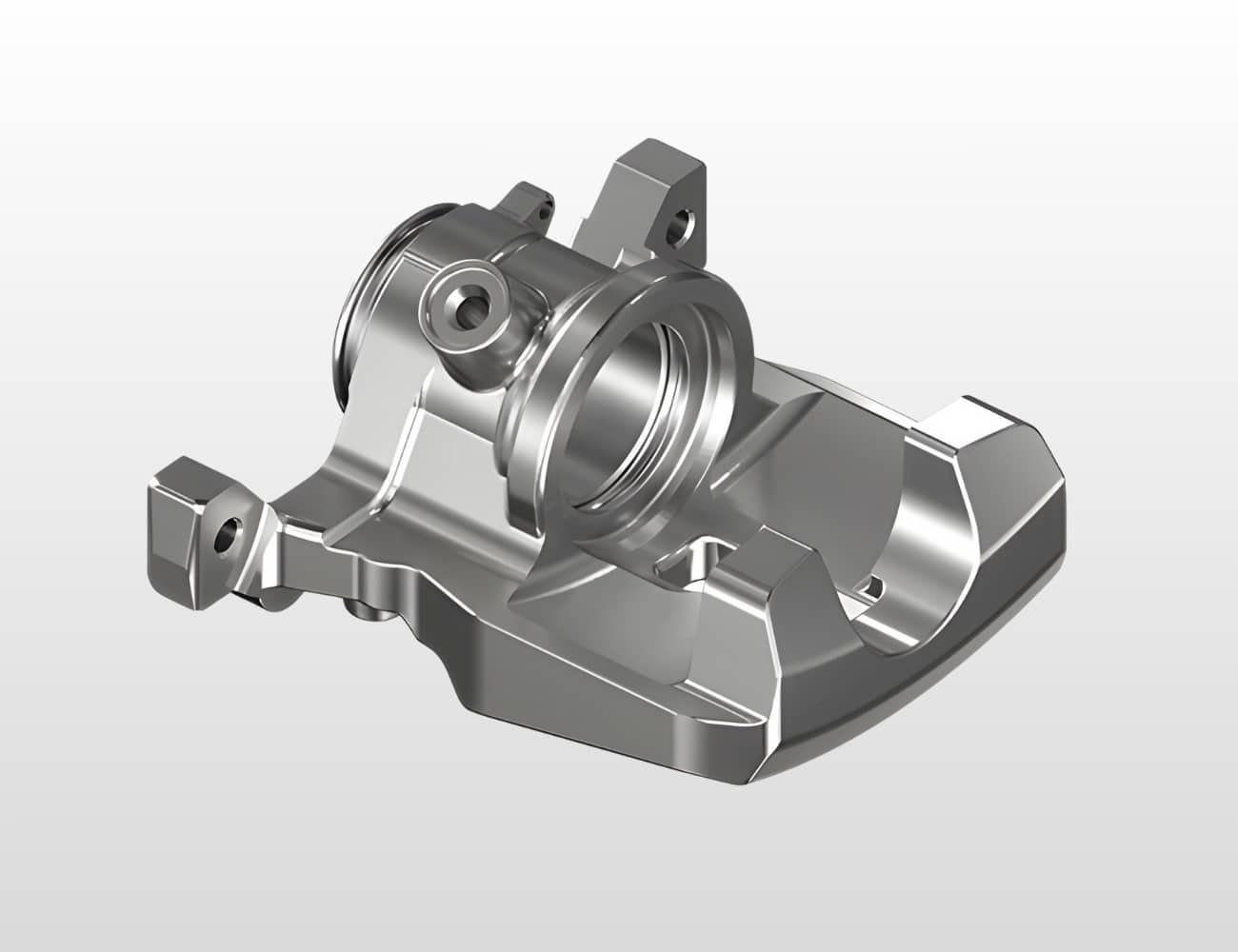

What is a Brake Caliper?

A brake caliper is the hydraulic clamp assembly that houses brake pistons and holds brake pads against the rotor to generate friction for vehicle stopping. It contains hydraulic cylinders, piston bores, mounting brackets, and bleeder valves while managing fluid pressure and pad positioning. Brake calipers are used in passenger cars, SUVs, commercial trucks, motorcycles, racing vehicles, and heavy equipment. Their critical function involves converting hydraulic pressure into mechanical clamping force, maintaining equal pad contact across the rotor surface, withstanding thermal loads from repeated braking, and ensuring consistent, fade-free stopping performance under all driving conditions.

Key Technical Requirements

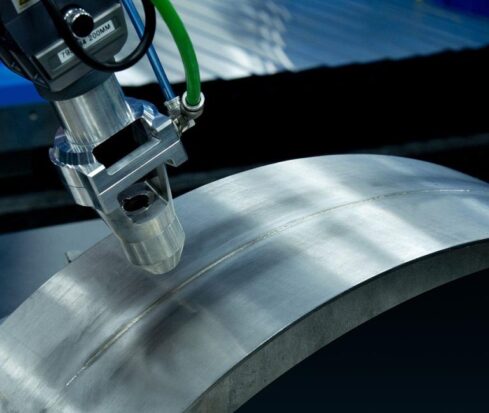

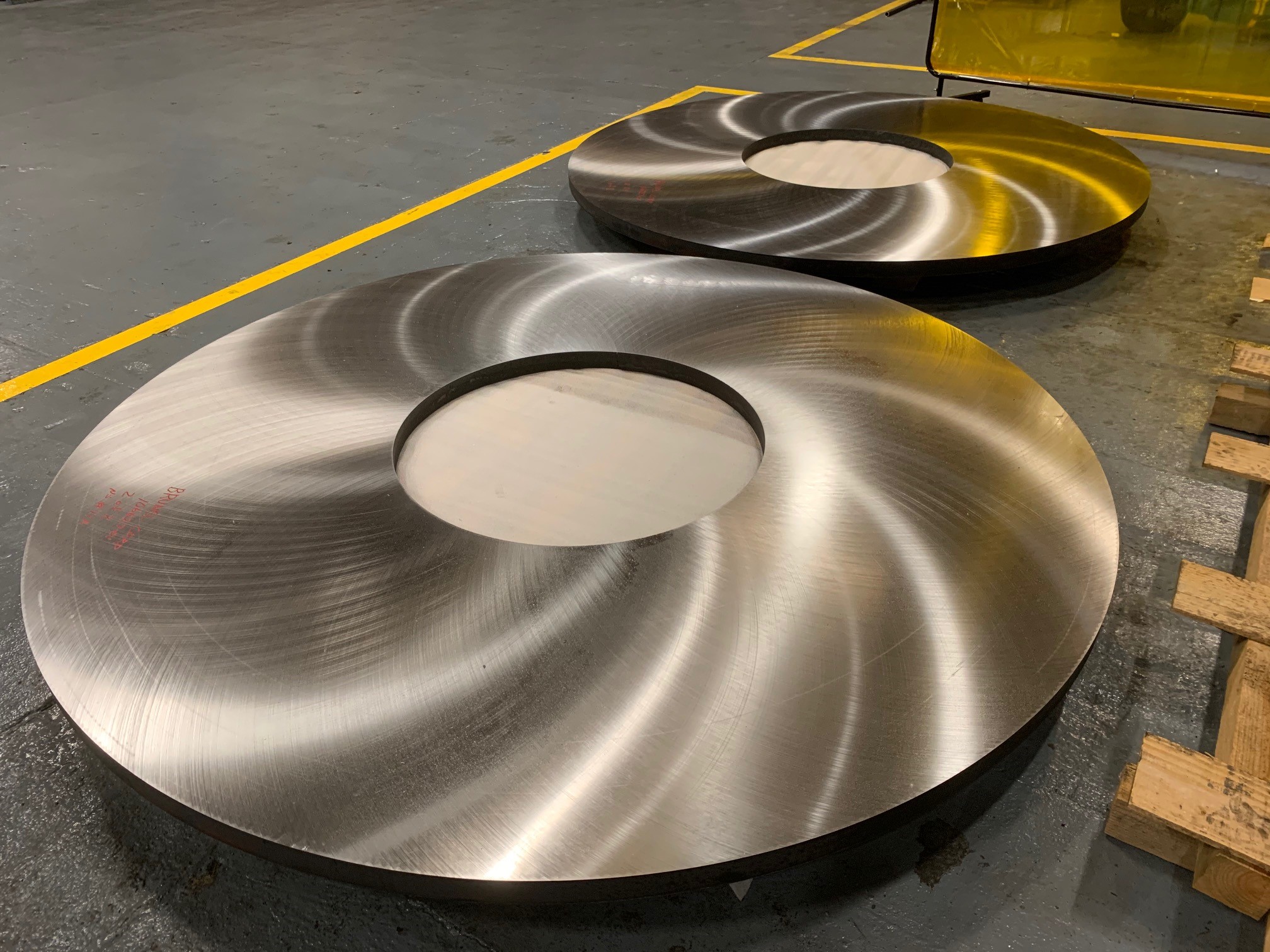

Brake calipers CNC machining requires extreme precision for piston bore alignment, mounting hole positioning, and sealing surface flatness. Typical tolerances range from ±0.001″ to ±0.003″ for critical features like piston bores, mounting faces, and hydraulic ports. Material specifications include aluminum alloys (6061-T6, 7075) for lightweight performance applications, cast iron for heavy-duty vehicles, and billet aluminum for racing calipers. Surface finish requirements are critical: piston bores need 8-16 Ra for proper seal function and smooth piston travel, while mounting surfaces require 32-63 Ra for secure bracket attachment. Piston bore concentricity must maintain ±0.0005″ for even pad wear. Brake calipers must withstand hydraulic pressures up to 2,000 psi, operating temperatures exceeding 600°F during heavy braking, corrosion from brake fluid and road salt, and repetitive thermal cycling throughout their service life.

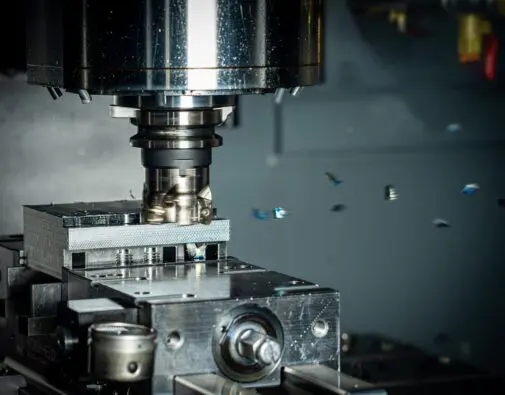

Manufacturing Challenges & Solutions

Machining brake calipers presents significant challenges due to complex internal hydraulic passages, multiple precision piston bores requiring perfect alignment, thin-walled sections prone to distortion, and the need for exceptional surface finishes in seal areas. Material hardness variations affect tool life and dimensional consistency. Achieving proper piston bore straightness and surface finish while maintaining tight positional tolerances across multiple bores demands advanced tooling and rigid machining setups.

Yicen Precision addresses these challenges using state-of-the-art 5-axis CNC machining centers that enable complex angle machining and complete feature access in minimal setups. Our advanced CAM software creates optimized tool paths that control heat generation and minimize part deflection. We employ specialized deep-hole boring tools and precision honing equipment for consistent piston bore geometry and surface finish. Climate-controlled machining environments ensure dimensional stability during operations. Custom fixtures provide rigid support without inducing stress in thin sections. Our quality control measures include comprehensive CMM inspection of all critical dimensions, bore straightness verification using air gauging, surface finish measurement, and hydraulic pressure testing.

Applications & Use Cases

Brake calipers CNC machining serves diverse automotive and motorsport applications:

- Passenger Vehicle Manufacturing – Fixed and floating brake calipers for sedans, SUVs, and compact cars in OEM production (Toyota, Honda, Ford assemblies)

- High-Performance and Racing – Multi-piston billet brake calipers for NASCAR, Formula racing, track-day vehicles, and performance street builds

- Commercial Truck and Fleet – Heavy-duty brake calipers for Class 8 trucks, delivery vehicles, buses, and commercial transport applications

- Motorcycle and Powersports – Lightweight brake calipers for sport bikes, cruisers, ATVs, UTVs, and off-road motorcycles

- Electric Vehicle Braking Systems – Regenerative braking-compatible calipers for EV and hybrid platforms with integrated electronic controls

- Aftermarket Performance Upgrades – Big brake kit calipers for enthusiast upgrades, track conversions, and towing applications

- Classic Vehicle Restoration – Reverse-engineered and modernized brake calipers for vintage car rebuilds with improved braking performance

Why Choose Yicen Precision for Brake Calipers?

Yicen Precision specializes in complex brake calipers CNC machining with industry-leading turnaround times for both prototype development and production volumes. Our scalable manufacturing capabilities support custom one-off racing calipers and high-volume OEM production runs with consistent precision and reliability. We provide comprehensive engineering support including DFM consultation to optimize piston configurations, weight reduction, and thermal management features. Complete material traceability with certified documentation ensures compliance with automotive safety standards and regulations. Our cost-effective solutions utilize advanced multi-axis machining, precision boring operations, and automated inspection processes without compromising the safety-critical precision your brake caliper applications demand. Contact us today for technical consultation and custom brake calipers machining quotes.