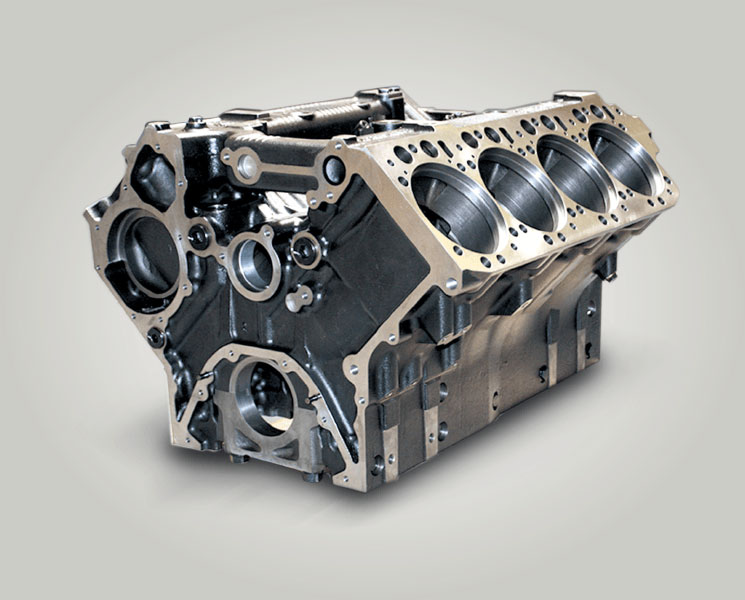

What is a Differential Case?

A differential case is the central housing assembly in a vehicle’s differential that contains the ring gear, spider gears, pinion gears, and side gears while managing torque distribution between drive wheels. It provides mounting surfaces for bearings, ring gear attachment, and axle shaft interfaces while maintaining proper gear mesh alignment. Differential cases are used in passenger cars, SUVs, pickup trucks, commercial vehicles, performance cars, and off-road equipment. Their critical function involves housing differential gear assemblies, transferring torque from the driveshaft to axle shafts, allowing wheels to rotate at different speeds during turns, supporting bearing loads, and maintaining structural rigidity under acceleration, deceleration, and cornering forces throughout demanding driving conditions.

Key Technical Requirements

Differential cases CNC machining requires extreme precision for bearing bore alignment, ring gear mounting face runout, and axle spline concentricity. Typical tolerances range from ±0.001″ to ±0.003″ for critical features like bearing journals, ring gear mounting surfaces, and gear mesh positioning. Material specifications include forged steel alloys (8620, 4340) for high-strength applications, nodular cast iron for standard duty vehicles, and aluminum alloys (7075) for lightweight racing differentials. Surface finish requirements are critical: bearing bores need 16-32 Ra for proper bearing fit and retention, while ring gear mounting faces require 32-63 Ra for secure bolt torque transfer. Ring gear runout must maintain 0.003″ TIR or less for proper gear mesh. Differential cases must withstand torque loads exceeding 1,500 lb-ft in performance applications, impact loads from wheel hop and traction events, operating temperatures from -40°F to 300°F, and resist fatigue, gear oil exposure, and stress concentration throughout their operational life.

Manufacturing Challenges & Solutions

Machining differential cases presents significant challenges due to large component size, multiple precision bearing bores requiring exact alignment, ring gear mounting surfaces demanding minimal runout, and complex internal cavities for gear clearance. Material hardness in forged steel components causes accelerated tool wear. Maintaining concentricity between input pinion axis and ring gear center while achieving tight tolerances on bearing journals requires advanced fixturing and inspection capabilities.

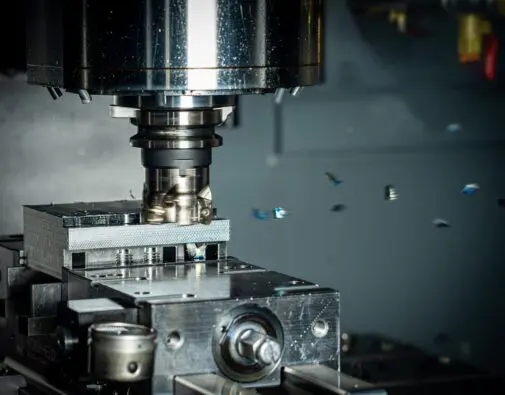

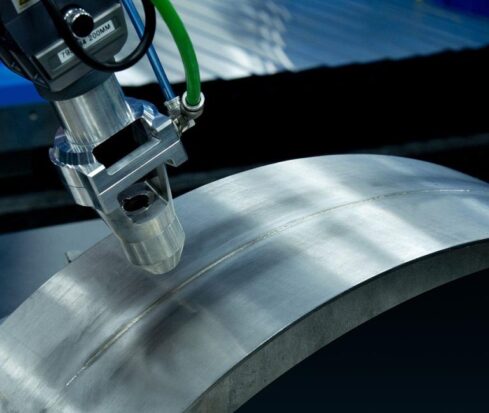

Yicen Precision addresses these challenges using state-of-the-art 5-axis CNC machining centers with extended work envelopes and high-rigidity construction for heavy differential case components. Our advanced CAM software creates optimized tool paths that control cutting forces and minimize deflection during heavy stock removal. We employ precision line boring systems and custom tooling for consistent bearing bore alignment across multiple journals. Temperature-controlled machining environments prevent thermal expansion affecting dimensional accuracy. Heavy-duty fixtures provide stable workholding without inducing stress or distortion. Our quality control measures include comprehensive CMM inspection of all critical dimensions, bearing bore alignment verification using laser measurement systems, ring gear mounting face runout measurement with dial indicators, and gear mesh pattern validation.

Applications & Use Cases

Differential cases CNC machining serves diverse automotive and industrial applications:

- Passenger Vehicle Production – Open and limited-slip differential cases for sedans, SUVs, and crossovers in OEM manufacturing (Ford, GM, Chrysler assemblies)

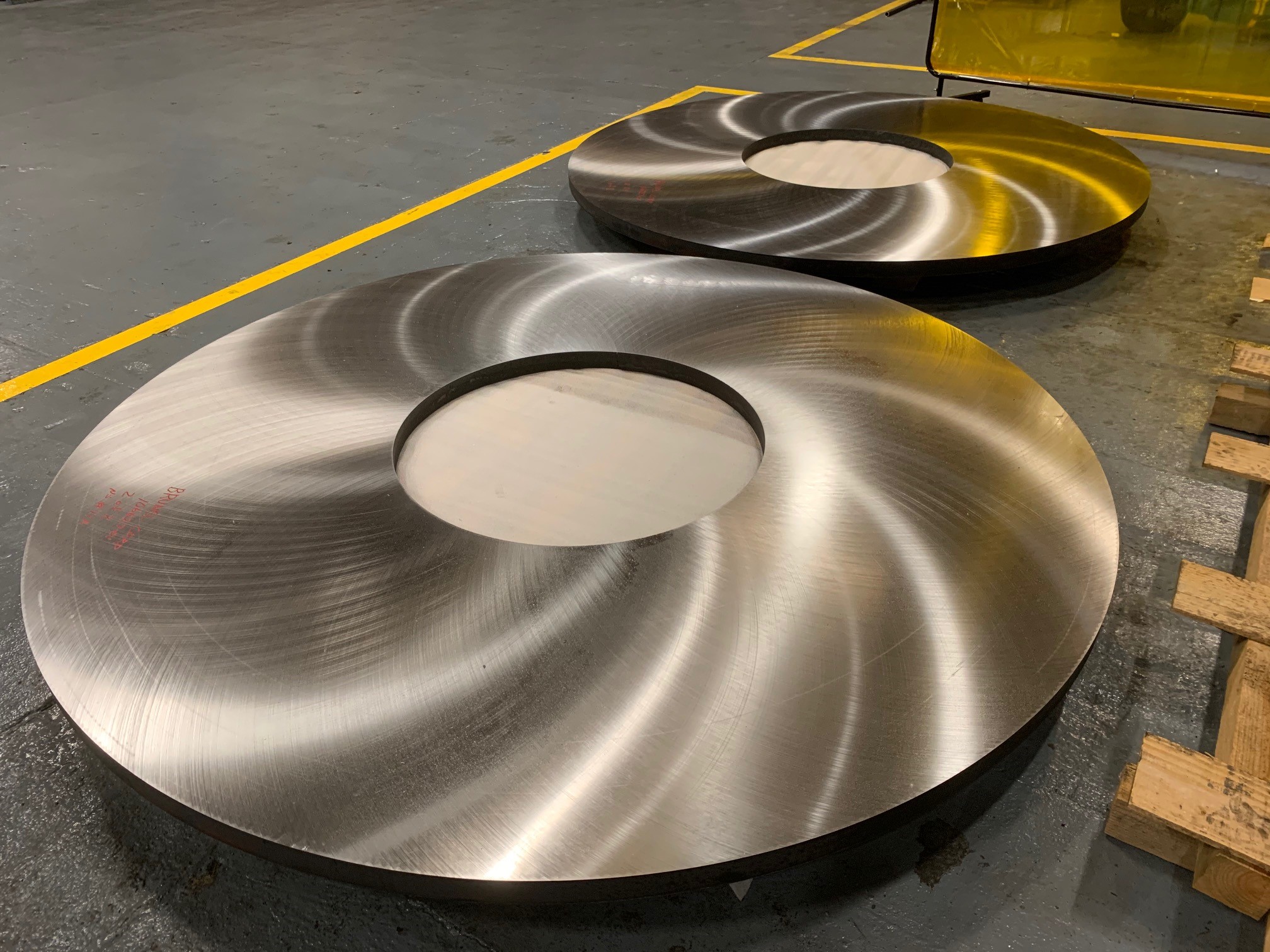

- Performance and Racing Applications – Lightweight differential cases for drag racing, road racing, drifting, and high-performance street builds with upgraded strength

- Heavy-Duty Commercial Trucks – Robust differential cases for Class 8 trucks, delivery fleets, construction equipment, and agricultural machinery with high torque capacity

- Off-Road and 4×4 Vehicles – Heavy-duty differential cases for rock crawling, mud racing, overlanding rigs, and expedition vehicles with reinforced construction

- All-Wheel Drive Systems – Center differential cases for AWD and 4WD vehicles including crossovers, SUVs, and performance sedans

- Aftermarket Performance Upgrades – Custom differential cases for locker installations, gear ratio changes, and strength upgrades for modified vehicles

- Classic Vehicle Restoration – Reverse-engineered differential cases for vintage car rebuilds, hot rods, and classic truck restorations with modern improvements

Why Choose Yicen Precision for Differential Cases?

Yicen Precision specializes in complex differential cases CNC machining with industry-leading turnaround times for both prototype development and production volumes. Our scalable manufacturing capabilities support custom one-off racing differentials and high-volume OEM production runs with consistent dimensional accuracy and structural integrity. We provide comprehensive engineering support including DFM consultation to optimize rib structures, wall thickness, weight reduction, and mounting configurations for maximum strength-to-weight ratios. Complete material traceability with certified mill test reports and documentation packages ensures compliance with automotive drivetrain standards. Our cost-effective solutions leverage multi-axis machining efficiency, optimized cutting strategies, and automated inspection processes without compromising the precision and reliability your differential case applications demand. Contact us today for technical consultation and custom differential cases machining quotes.