Absolutely. We offer reverse engineering services using 3D scanning and CAD modeling to recreate engine blocks for classic restorations, discontinued models, and custom builds with improved specifications over original designs.

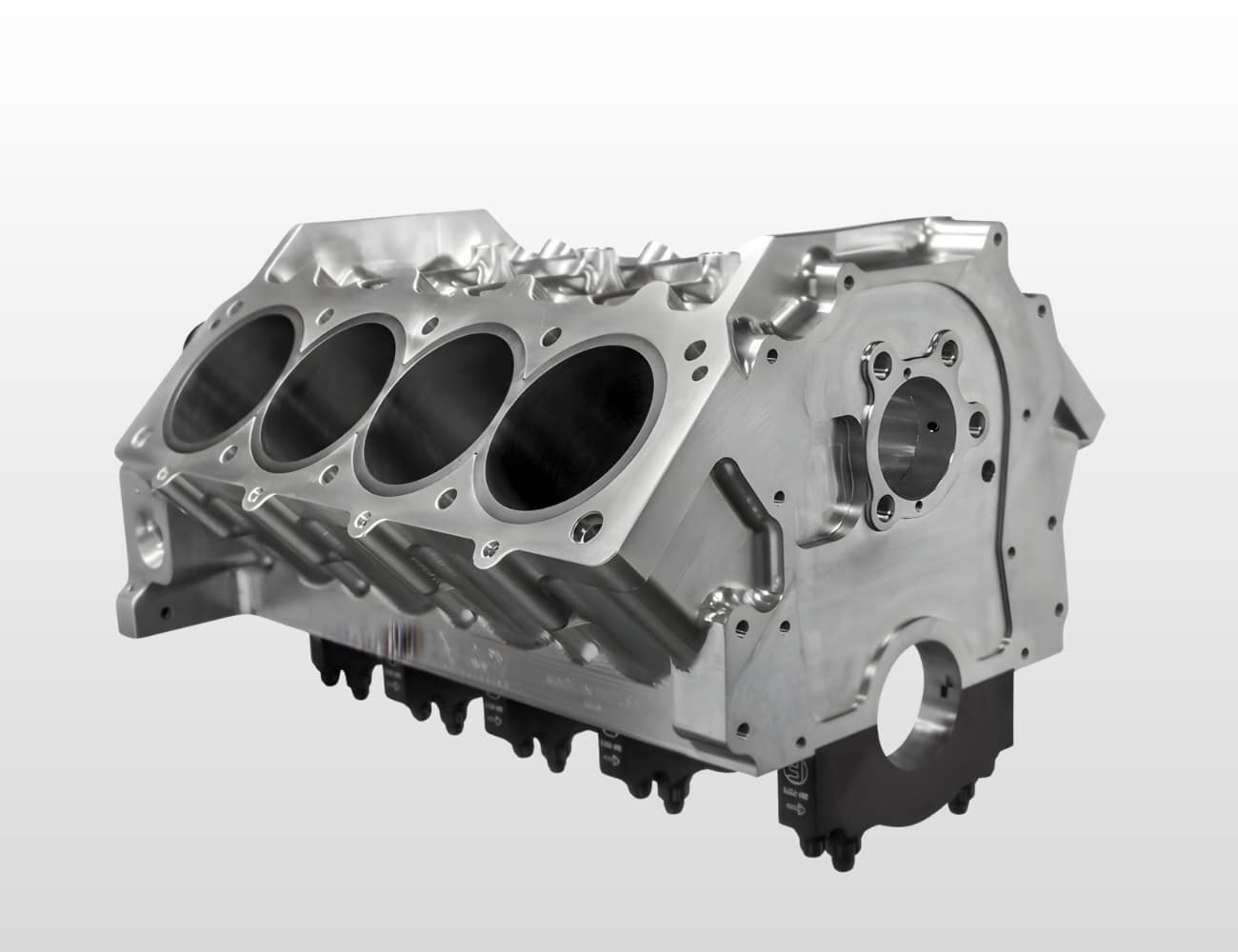

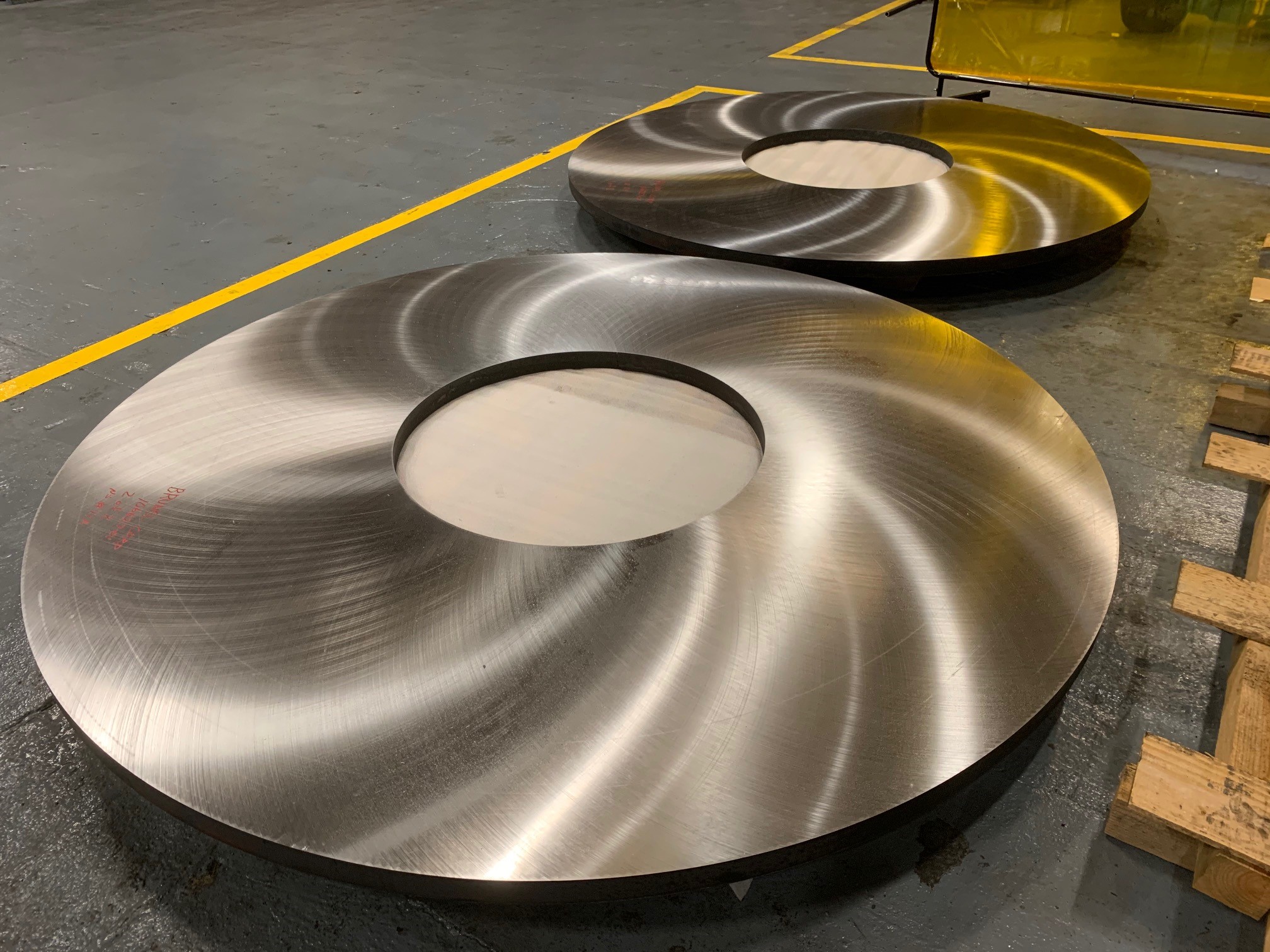

Precision-engineered engine blocks manufactured with advanced CNC technology for exceptional durability and dimensional accuracy. Our automotive-grade machining ensures tight tolerances, superior surface finishes, and consistent performance across all vehicle applications. Get your custom engine blocks CNC machining quote today.

Machining services delivers high-precision, production-ready parts for the automotive industry, supporting everything from prototyping to large-scale manufacturing. We machine complex components with tight tolerances, optimized for performance, durability, and repeatability ideal for engines, drivetrains, chassis, and custom assemblies. Whether you’re building high-performance vehicles or electric systems, our advanced CNC capabilities ensure every part meets strict quality and engineering standards. Reach out today to discuss your automotive machining needs and request a free quote.

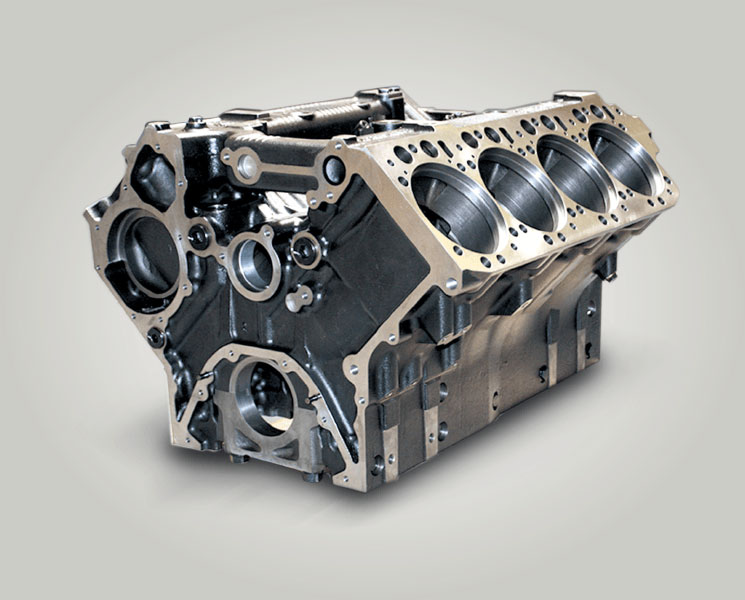

Engine blocks serve as the structural foundation of any automotive powertrain, housing cylinders, pistons, and crankshafts while withstanding extreme mechanical stresses and temperatures. These critical components require precision manufacturing to ensure proper alignment, optimal performance, and long-term reliability across passenger vehicles, commercial trucks, and high-performance racing applications.

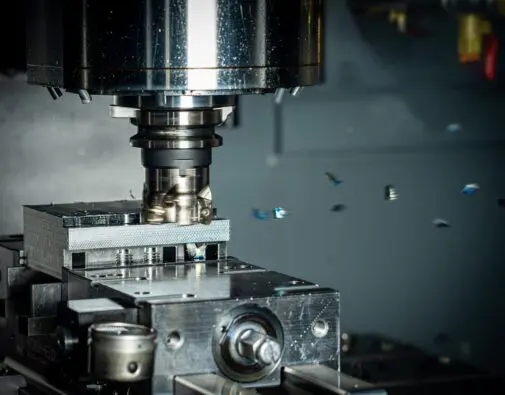

Yicen Precision delivers superior engine blocks CNC machining through advanced 5-axis milling centers and multi-axis lathes equipped with precision tooling systems. We machine engine blocks from aluminum alloys, cast iron, and specialty steel materials with repeatable accuracy. Our ISO-compliant processes and rigorous quality standards ensure every engine block meets exact specifications for tight tolerances and complex geometries.

From high-performance prototypes to production-ready parts, we machine precision components that meet the demanding standards of the automotive sector.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

At CNC Machine Services, we offer high-performance automotive materials like aluminum alloys, stainless steels, titanium, and nickel alloys. These materials are engineered for superior strength, heat resistance, and durability, ensuring optimal performance for critical automotive components. Whether it’s for engine parts, chassis, or exhaust systems, our precision machining guarantees the highest quality for every application.

At CNC Machine Services, we offer premium automotive surface finishes like anodizing, nickel plating, and powder coating to enhance strength, corrosion resistance, and appearance. Our finishes ensure your automotive parts are durable, reliable, and ready for demanding applications.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

An engine block, or cylinder block, is the main structural component of an internal combustion engine. It houses the cylinders, pistons, crankshaft, and coolant passages while providing mounting surfaces for the cylinder head and oil pan. Engine blocks are used in passenger cars, commercial trucks, marine vessels, and industrial equipment. Their critical function involves containing combustion forces, managing thermal loads, maintaining precise component alignment, and ensuring structural integrity under continuous operational stress.

Engine blocks CNC machining demands exceptional precision for cylinder bore alignment, deck flatness, and bearing journal concentricity. Typical tolerances range from ±0.0005″ to ±0.002″ for critical surfaces, with high-performance applications requiring even tighter specifications. Material specifications include aluminum alloys (A356, A380) for lightweight designs, gray cast iron for durability, and ductile iron for heavy-duty applications. Surface finish requirements vary by feature: cylinder bores need 16-32 Ra for proper piston ring seating, while deck surfaces require 32-63 Ra for head gasket sealing. Engine blocks must withstand combustion pressures exceeding 1,000 psi, operating temperatures from -40°F to 400°F, and resist thermal expansion, coolant corrosion, and vibrational fatigue.

Machining engine blocks presents challenges due to large component size, complex internal passages, multiple intersecting bores, and extreme alignment precision requirements. Material hardness variations in castings cause tool wear and dimensional inconsistencies. Thin-walled sections in modern lightweight designs risk distortion during machining operations.

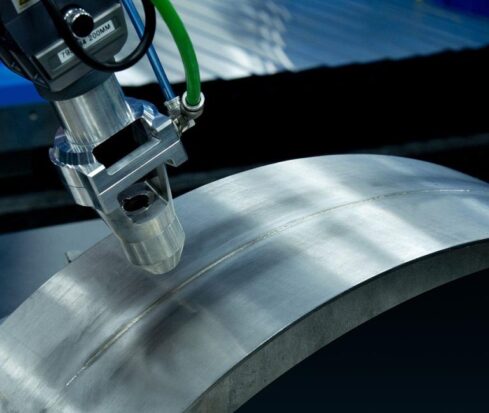

Yicen Precision overcomes these challenges with state-of-the-art 5-axis CNC machining centers featuring high-torque spindles and rigid construction for vibration-free cutting. Our advanced CAM software optimizes tool paths to minimize stress on thin-walled sections. We use precision boring heads and custom tooling for consistent cylinder bore finishes and alignment. Temperature-controlled environments prevent thermal expansion errors, while specialized fixtures ensure repeatable positioning. Our quality control includes comprehensive CMM inspection, bore gauge verification, and deck flatness measurement to guarantee dimensional accuracy.

Engine blocks CNC machining serves diverse automotive and industrial sectors:

Yicen Precision specializes in complex engine blocks CNC machining with fast turnaround times from prototype development to full-scale production. Our scalable manufacturing supports low-volume custom projects and high-volume production runs with consistent dimensional accuracy. We provide comprehensive engineering support including DFM consultation to optimize designs for manufacturability, reduce weight, and improve cost efficiency. Complete material traceability with certified mill test reports ensures compliance with OEM specifications. Our cost-effective solutions leverage optimized tool paths, efficient material utilization, and process automation without compromising precision or quality. Contact us today for technical consultation and custom engine block machining quotes.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

Do you provide reverse engineering for discontinued engine blocks?

Absolutely. We offer reverse engineering services using 3D scanning and CAD modeling to recreate engine blocks for classic restorations, discontinued models, and custom builds with improved specifications over original designs.

Can you handle both prototype and production engine blocks?

Yes, we support complete development cycles from single prototype engine blocks for R&D testing to production runs of thousands of units. Our flexible systems scale efficiently while maintaining consistent quality across all volumes.

What tolerances can you achieve for engine block cylinder bores?

We routinely achieve tolerances of ±0.0005″ to ±0.002″ on cylinder bores, crankshaft journals, and deck surfaces. For racing applications, we maintain even tighter specifications down to ±0.0003″ using specialized tooling and inspection protocols.

Which materials do you machine for automotive engine blocks?

We machine aluminum alloys (A356, A380, 6061), gray cast iron (Class 30-40), ductile iron, and specialty steel alloys. Material selection depends on weight requirements, thermal properties, strength specifications, and application demands.