A. What are Custom Buttons, Switches, and Dials?

Custom buttons, switches, and dials are precision-machined user interface components that enable physical interaction and control of electronic devices. These tactile controls include rotary knobs for volume and parameter adjustment, push buttons for function activation, toggle switches for mode selection, slider controls for continuous adjustment, encoder dials with detent feedback, capacitive touch buttons with decorative surfaces, mechanical key switches for keyboards, and joystick components for gaming controllers. They are essential in audio equipment, automotive infotainment systems, smart home controls, medical devices, industrial equipment, gaming peripherals, kitchen appliances, and professional instruments.

The primary functions of these components include translating physical user input into electrical signals, providing tactile and auditory feedback confirming user actions, enabling precise parameter adjustment with repeatable accuracy, and contributing to product aesthetics and brand identity. Their design directly impacts user satisfaction, operational efficiency, perceived product quality, and overall device usability. Precision manufacturing ensures consistent operation through millions of activation cycles while maintaining aesthetic appearance.

B. Key Technical Requirements

Manufacturing custom buttons, switches, and dials demands exceptional attention to mechanical, tactile, and aesthetic specifications. Dimensional tolerances for shaft diameters typically range from ±0.002″ to ±0.005″ to ensure smooth rotation with minimal play in bearing surfaces while preventing binding. Concentricity tolerances of 0.002″ TIR or better maintain balanced rotation without wobble that would degrade user experience.

Thread specifications for mounting require precise pitch control within ±0.001″ and consistent major/minor diameter tolerances to ensure reliable attachment without cross-threading or loosening during operation. Surface finish requirements vary dramatically by application—grip surfaces may specify knurled patterns with consistent depth and spacing, while decorative surfaces demand Ra values below 16 microinches for mirror-like appearance suitable for anodizing or plating.

Detent mechanisms for rotary controls require precise machining of indexing features with angular accuracy within ±0.5 degrees and consistent detent spacing to provide uniform tactile feedback across the rotation range. Spring retention grooves and snap-fit features must maintain tight tolerances of ±0.003″ for proper retention force without premature wear or failure.

Material specifications balance aesthetic requirements with functional properties including wear resistance for high-cycle applications, corrosion resistance for exposed controls, electrical conductivity for switch contacts, and appropriate density for desired tactile weight. Wall thickness specifications must provide structural rigidity while enabling features like internal cable routing or electronics integration, typically ranging from 0.040″ to 0.120″ depending on size and material.

Aesthetic requirements include flawless surface finishes free from tool marks or blemishes, precise alignment of decorative features like indicator lines or logos, and consistent appearance across production runs. Ergonomic considerations demand comfortable grip surfaces with appropriate texture depth and spacing for secure operation without discomfort during extended use.

C. Manufacturing Challenges & Solutions

Machining custom buttons, switches, and dials presents significant challenges including achieving mirror-finish surfaces on complex three-dimensional forms, producing consistent knurling patterns across cylindrical surfaces, maintaining tight concentricity through multiple operations, and creating precise detent features with uniform tactile feedback. Small component sizes amplify the impact of any dimensional variation on fit and function. Thin-walled sections required for weight reduction or aesthetic proportions are susceptible to distortion during machining.

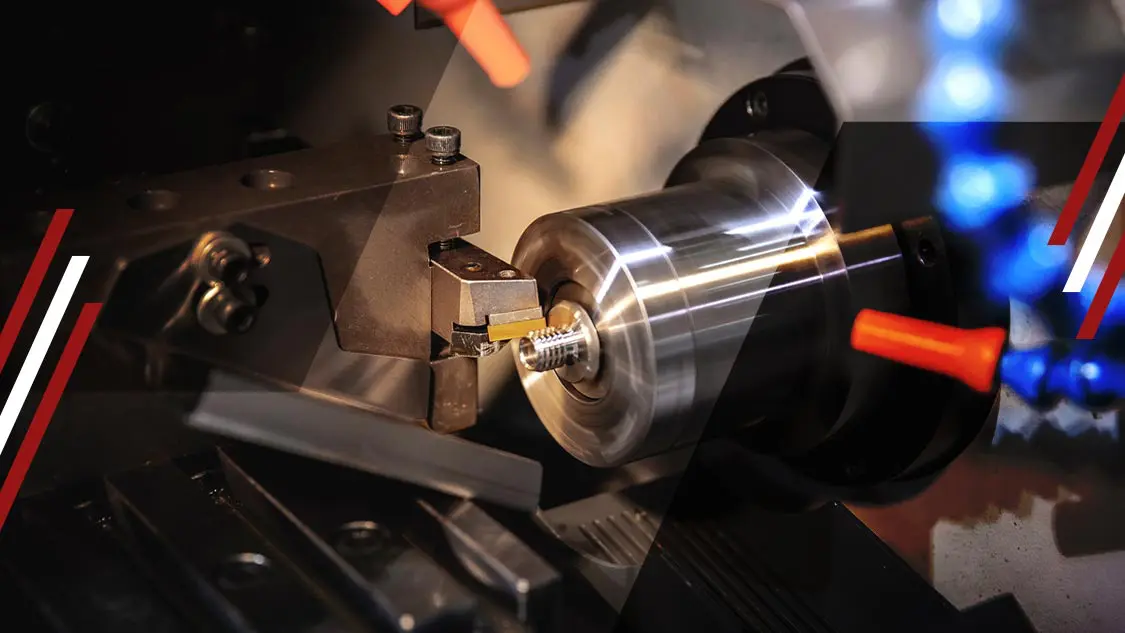

Yicen Precision addresses these challenges through specialized manufacturing approaches developed specifically for precision control components. Our Swiss-type CNC lathes enable complete machining of rotary components in single operations, maintaining perfect concentricity between all diameters while producing complex features including threads, grooves, and knurling without repositioning. This eliminates cumulative setup errors that could compromise rotational smoothness.

For knurling operations, we utilize precision form knurling tools with carefully controlled feed rates and depths that produce consistent diamond or straight patterns with uniform appearance and tactile properties. Advanced tooling systems minimize workpiece deflection during pattern formation. Surface finishing employs progressive cutting strategies with multiple passes at decreasing depths, followed by specialized polishing operations for components requiring mirror finishes.

Detent feature machining utilizes ball-end mills and form tools with precise geometric control, creating consistent indexing profiles verified through coordinate measurement. Our CAM programming incorporates advanced 5-axis strategies for complex button cap geometries, maintaining constant surface finish across compound curves and transitional radii. Custom workholding fixtures support delicate components during finishing operations without marring surfaces.

Quality control includes comprehensive CMM inspection of critical dimensions, optical profilometry for surface finish verification, and functional testing of rotational smoothness, detent consistency, and tactile feedback characteristics. Concentricity and perpendicularity verification ensures balanced operation. Aesthetic inspection under controlled lighting validates surface quality and finish consistency across production batches.

D. Applications & Use Cases

Precision-machined custom buttons, switches, and dials enable intuitive control across diverse consumer electronics applications:

- Premium Audio Equipment: Volume knobs, input selector switches, tone control dials, and balance adjustment knobs for amplifiers, receivers, and mixing equipment

- Smart Home Controls: Rotary thermostats, dimmer switches, scene selection buttons, and touch-sensitive control panels for home automation systems

- Gaming Peripherals: Mechanical keyboard switches, joystick components, trigger assemblies, and customizable control knobs for professional gaming equipment

- Kitchen Appliances: Stainless steel control knobs, temperature selector dials, mode selection buttons, and timer adjustment controls for ovens, cooktops, and appliances

- Automotive Infotainment: Climate control knobs, audio system controls, multi-function switches, and haptic feedback buttons for vehicle interfaces

- Professional Instruments: Precision adjustment knobs, parameter selection switches, and calibration dials for laboratory equipment and test instruments

- Wearable Devices: Crown controls for smartwatches, mode selection buttons for fitness trackers, and adjustment dials for activity monitors

E. Why Choose Yicen Precision for Custom Buttons, Switches, and Dials?

Yicen Precision delivers exceptional value for custom buttons, switches, and dials CNC machining through our specialized expertise in precision control component manufacturing. Our rapid prototyping services provide functional samples within days, enabling ergonomic evaluation, tactile feedback testing, and design refinement before committing to production tooling and surface finishing processes.

We offer flexible scalability from boutique products requiring limited runs with unique customization through mass-market consumer electronics demanding millions of units annually, maintaining precision and tactile consistency regardless of order volume. Our engineering team provides expert DFM consultation focused on control component optimization, including recommendations for knurling patterns, detent design, material selection, and manufacturing efficiency improvements that reduce costs while enhancing user experience.

Complete material traceability with certified documentation supports quality assurance requirements and regulatory compliance for consumer products. Our cost-effective solutions leverage efficient machining strategies, optimized tooling selection, and process refinement that deliver superior custom buttons, switches, and dials at competitive pricing without compromising the precision, tactile quality, or premium aesthetics your products demand.

With dedicated project management, transparent communication throughout development and production, commitment to delivery schedules, and comprehensive post-delivery support, we become your trusted manufacturing partner for creating exceptional user interface components that delight customers and differentiate your products in competitive markets.