A. What are Laptop and Desktop Housings?

Laptop and desktop housings are precision-machined structural enclosures that protect, support, and integrate the electronic components of personal computing devices. These critical assemblies include laptop unibody chassis with integrated keyboard decks, bottom covers with ventilation grilles and battery compartments, display bezels and lid assemblies, desktop tower cases with drive bays and expansion slots, all-in-one computer rear housings with thermal management systems, small form factor PC cases, and workstation chassis with modular component access. They are essential in consumer notebooks, gaming laptops, business ultrabooks, desktop workstations, gaming PCs, home theater computers, and professional computing systems.

The primary functions of laptop and desktop housings include providing rigid structural support for motherboards and displays, protecting sensitive electronics from physical damage and electrostatic discharge, facilitating efficient airflow and thermal dissipation through strategically placed vents and channels, shielding electromagnetic interference to ensure regulatory compliance and prevent signal disruption, enabling user access to ports and expansion slots while maintaining security, and delivering premium aesthetics that communicate brand identity and product quality. Their design directly impacts device durability, thermal performance, user ergonomics, and brand perception in highly competitive computing markets.

B. Key Technical Requirements

Manufacturing laptop and desktop housings demands comprehensive attention to structural, thermal, and aesthetic specifications. Dimensional tolerances for display mounting surfaces and hinge assemblies typically range from ±0.005″ to ±0.010″ to ensure proper alignment, smooth operation, and gap consistency around displays. Flatness specifications for motherboard mounting surfaces require tolerances within 0.010″ across large areas to prevent PCB flexing that could damage solder joints or connectors.

Material specifications balance strength, weight, and thermal properties. Aluminum alloys provide excellent stiffness-to-weight ratios with thermal conductivity of 150-200 W/m·K, ideal for integrated heat dissipation. Wall thickness specifications typically range from 0.060″ to 0.120″ for laptop chassis, balancing structural rigidity with weight optimization. For ultra-thin laptop designs, walls as thin as 0.040″ may be specified with strategic ribbing for reinforcement.

Surface finish requirements vary by application and visibility. External decorative surfaces demand Ra values below 32 microinches for premium appearance suitable for anodizing or powder coating. Internal surfaces may specify Ra 63-125 microinches with focus on functionality rather than aesthetics. Threaded insert locations require precise positioning within ±0.010″ and perpendicularity within 0.005″ to ensure reliable fastener engagement across numerous assembly and disassembly cycles.

Thermal management features include precision-machined ventilation slots with specific width and spacing tolerances, heat sink mounting surfaces with flatness within 0.003″ for optimal thermal interface material contact, and internal airflow channels with smooth transitions to minimize turbulence. EMI shielding specifications require conductive surface treatments and precision-ground mating surfaces for effective electromagnetic containment. Mechanical strength must withstand drop testing, typically from heights of 30″ for laptops and greater impacts for desktop housings, while maintaining structural integrity and protecting internal components.

C. Manufacturing Challenges & Solutions

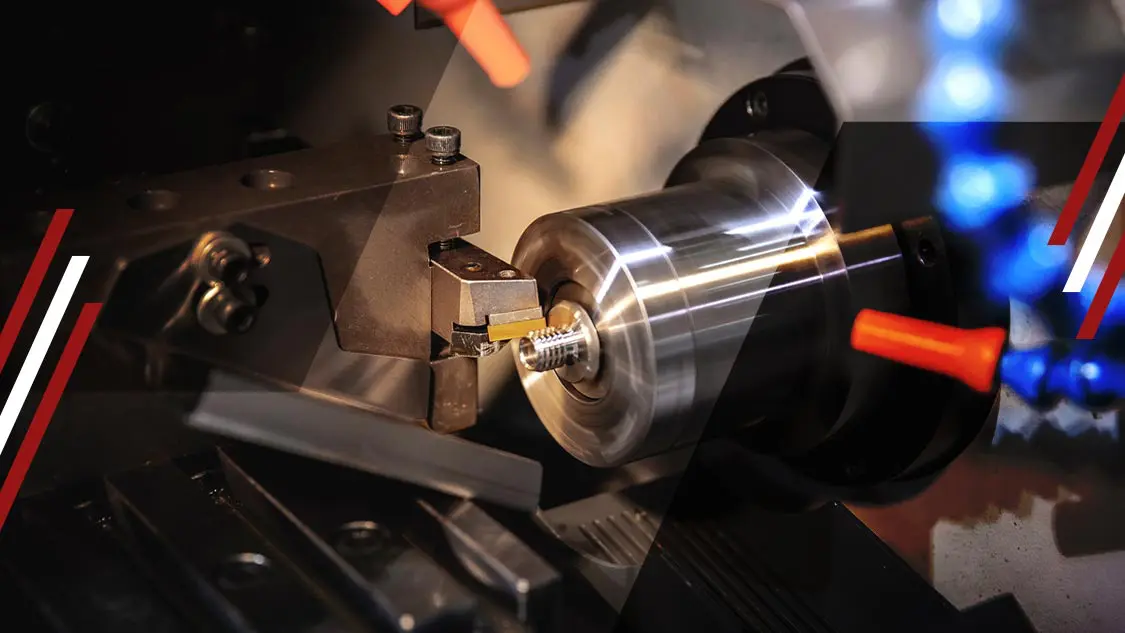

Machining laptop and desktop housings presents formidable challenges including producing large, thin-walled structures susceptible to distortion from machining forces and thermal expansion, maintaining dimensional accuracy across substantial surface areas, creating complex internal geometries for component integration and cable routing, and achieving premium surface finishes on visible areas while efficiently machining functional internal features. Aluminum’s tendency to distort during material removal from large stock requires careful stress management. Producing hundreds of precise mounting holes and threaded inserts with consistent positioning across large chassis demands advanced fixturing and programming.

Yicen Precision addresses these challenges through strategic manufacturing approaches specifically developed for large-format enclosure production. Our large-bed 5-axis CNC machining centers accommodate housings up to 24″ x 18″ x 6″, enabling complete machining of laptop chassis and desktop cases in single or dual setups that maintain geometric relationships. Advanced CAM programming incorporates stress-relief machining strategies that remove material in balanced sequences, minimizing internal stress accumulation that could cause distortion.

Custom vacuum fixturing systems designed for thin-walled housings distribute holding forces uniformly across large surfaces, preventing deflection during machining operations while enabling access to all required features. High-speed machining strategies with optimized cutting parameters reduce cutting forces while maintaining productivity on aluminum alloys. For magnesium housings, we employ specialized cutting fluids and controlled environments to manage fire risk while achieving required surface quality.

Thermal management during machining includes programmed cool-down periods for large material removal operations and climate-controlled manufacturing environments maintaining ±2°F temperature stability to prevent thermal expansion affecting dimensional accuracy. Automated drilling and tapping operations ensure consistent positioning and perpendicularity of mounting holes across chassis, with coordinate-based programming eliminating cumulative positioning errors.

Quality control includes comprehensive CMM inspection of critical mounting surfaces, hinge locations, and display alignment features. Large-format optical scanning validates overall dimensional accuracy and surface contours across entire housings. Flatness measurement of motherboard mounting planes uses precision indicators and coordinate measuring techniques. Thermal performance validation through airflow simulation and prototype testing ensures ventilation designs meet cooling requirements. Assembly validation with actual motherboards, displays, and components confirms proper fitment and functionality before production release.

D. Applications & Use Cases

Precision-machined laptop and desktop housings enable reliable, attractive computing products across diverse consumer electronics applications:

- Consumer Laptops and Ultrabooks: Ultra-thin aluminum unibody chassis, display lid assemblies, keyboard decks with precision trackpad cutouts, and bottom covers with ventilation for mainstream computing

- Gaming Laptops: High-performance housings with aggressive styling, RGB lighting integration, enhanced cooling vents, and reinforced structures for powerful graphics and processors

- Business Notebooks and Workstations: Professional aluminum or magnesium chassis with security features, docking connectors, and durable construction for enterprise computing environments

- Desktop Tower Cases: Modular ATX and E-ATX chassis with drive bays, expansion slot provisions, front panel assemblies, and cable management features for DIY and pre-built systems

- All-in-One Computer Housings: Integrated display and computer housings with rear-mounted component access, VESA mounting provisions, and aesthetic stand integration

- Small Form Factor PCs: Compact Mini-ITX and Micro-ATX cases with optimized layouts, efficient thermal designs, and premium finishes for space-conscious computing

- Gaming Desktop Chassis: Tempered glass panel frames, RGB component showcasing, liquid cooling mounting provisions, and high-airflow designs for enthusiast gaming systems

E. Why Choose Yicen Precision for Laptop and Desktop Housings?

Yicen Precision stands as your premier manufacturing partner for laptop and desktop housings CNC machining through our extensive experience with large-format enclosure production and deep understanding of computing device requirements. Our rapid prototyping capabilities deliver functional housing prototypes within 7-10 days, enabling thermal validation, assembly testing, and design refinement before committing to production tooling and surface finishing processes.

We offer flexible scalability from innovative startup designs requiring limited pilot production through established manufacturers demanding tens of thousands of units monthly, maintaining precision and aesthetic consistency regardless of production volume. Our engineering team provides expert DFM consultation specifically focused on computer housing applications, including recommendations for thermal optimization, structural reinforcement, manufacturing efficiency, weight reduction, and cost-effective design modifications that preserve functionality and aesthetics.

Complete material traceability with certified documentation supports quality assurance and regulatory compliance requirements including FCC, CE, and RoHS certifications for electronic enclosures. Our cost-effective solutions leverage efficient machining strategies, optimized material utilization through nesting and remnant management, and process automation that deliver superior laptop and desktop housings at competitive pricing without compromising precision, thermal performance, or premium appearance.

With dedicated project management, transparent communication throughout development and production phases, commitment to delivery schedules supporting product launch timelines, and comprehensive quality documentation, we become your trusted manufacturing partner for bringing innovative computing products to market that users rely on daily for work, creativity, and entertainment.