A. What are Power Supply Housings?

Power supply housings are precision-engineered enclosures designed to contain, protect, and thermally manage power conversion electronics in consumer devices. These protective shells house transformers, rectifiers, voltage regulators, and control circuitry that convert AC to DC power or manage battery charging functions. They are used extensively in laptop adapters, desktop computer power supplies, smartphone chargers, gaming console power bricks, monitor power units, and external battery chargers.

The critical functions of power supply housings include providing electrical insulation to prevent shock hazards, dissipating heat generated during power conversion, shielding electromagnetic interference to prevent signal disruption, and protecting internal components from physical damage and environmental factors. Their design directly impacts device safety, thermal performance, regulatory compliance, and overall product reliability in diverse operating environments.

B. Key Technical Requirements

Manufacturing power supply housings demands careful consideration of electrical, thermal, and mechanical specifications. Dimensional tolerances typically range from ±0.005″ to ±0.010″ for mounting features and connector openings, ensuring proper alignment with internal PCBs and external cables. Wall thickness specifications must balance structural strength with weight optimization, typically ranging from 0.060″ to 0.120″ depending on material and application.

Material specifications prioritize thermal conductivity for aluminum housings, often requiring alloys with thermal conductivity above 120 W/m·K to efficiently dissipate heat from power components. For plastic housings, materials must meet UL94 V-0 flame retardancy ratings and withstand operating temperatures up to 85°C continuously. Surface finish requirements include smooth internal surfaces to prevent sharp edges near electrical components and external finishes providing corrosion resistance and aesthetic appeal.

Thermal management features require precise machining of heat sink fins with optimal spacing for natural or forced convection, ventilation slots positioned for airflow without compromising electrical safety, and thermal interface surfaces with flatness within 0.002″ for effective heat transfer. EMI shielding effectiveness demands proper contact between housing sections, often requiring precision-ground sealing surfaces and conductive gasket channels. Mechanical strength must withstand drop tests, typically 1 meter onto concrete surfaces, while maintaining structural integrity.

C. Manufacturing Challenges & Solutions

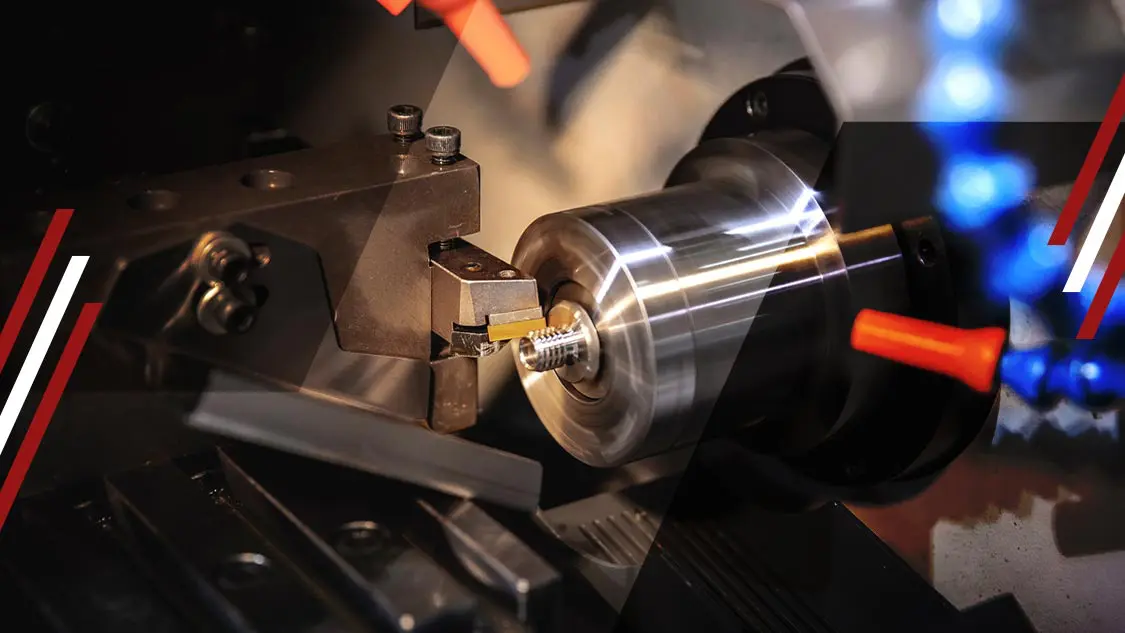

Machining power supply housings presents unique challenges including thin-walled sections susceptible to vibration and distortion, complex internal geometries for component clearance and airflow, and numerous precision features like mounting bosses, cable routing channels, and fastener locations. Aluminum housings require careful heat sink fin machining to prevent fin breakage while maintaining dimensional accuracy. Plastic housings demand specialized cutting parameters to prevent melting, chipping, or dimensional instability.

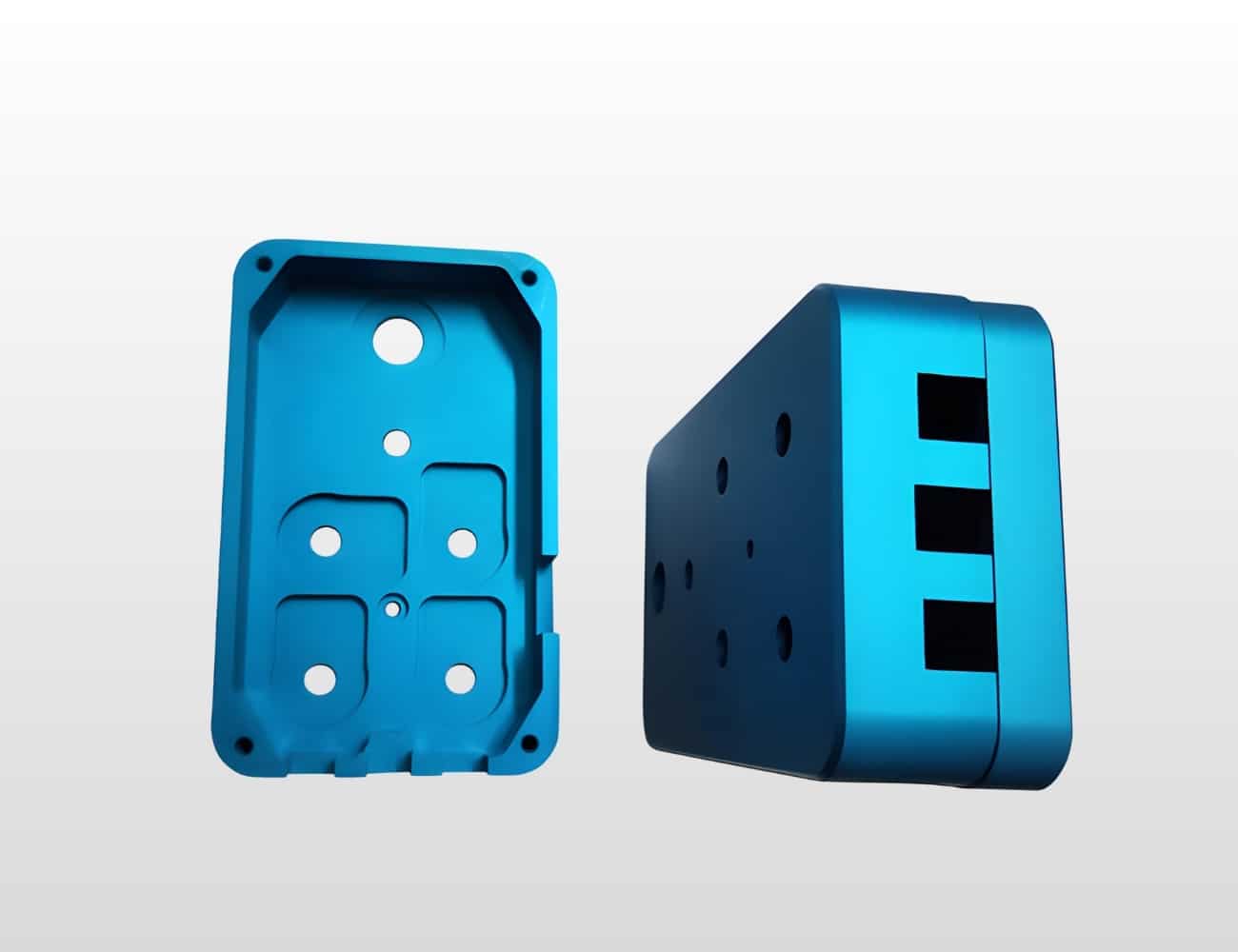

Yicen Precision overcomes these challenges through strategic machining approaches tailored to power supply housing requirements. Our 5-axis CNC machining centers enable efficient production of complex geometries including undercuts, internal pockets, and ventilation arrays in single setups, minimizing handling and improving accuracy. Advanced workholding fixtures specifically designed for thin-walled enclosures distribute clamping forces evenly, preventing distortion during machining operations.

For heat sink features, we employ high-speed machining strategies with optimized tool paths that reduce cutting forces while maintaining tight tolerances on fin spacing and height. Dedicated cooling strategies prevent thermal expansion during machining, ensuring dimensional stability. Our CAM programming incorporates adaptive toolpaths that adjust feed rates based on material engagement, preventing vibration and improving surface finish.

Quality control includes comprehensive CMM inspection of critical mounting features and connector openings, thermal imaging verification of heat sink designs using simulation validation, and dimensional verification of sealing surfaces for EMI shielding effectiveness. Flatness measurement of thermal interface surfaces ensures optimal heat transfer to internal components. Assembly validation confirms proper fit with mating components and fastener engagement.

D. Applications & Use Cases

Precision-machined power supply housings enable reliable power delivery across diverse consumer electronics applications:

- Laptop and Notebook Adapters: Compact power bricks with integrated heat sinks and cable management for portable computing power delivery

- Desktop Computer Power Supplies: ATX and SFX format enclosures with optimized airflow channels and mounting provisions for high-wattage systems

- Smartphone and Tablet Chargers: Miniature housings with efficient thermal management for fast-charging wall adapters and wireless charging pads

- Gaming Console Power Units: High-capacity enclosures with enhanced cooling for sustained high-power operation during gaming sessions

- Monitor and Display Power Supplies: Integrated and external power housings with EMI shielding for interference-free video signal quality

- Smart Home Device Adapters: Compact, aesthetically designed housings for IoT hubs, security cameras, and connected home appliances

- Audio Equipment Power Supplies: Low-noise enclosures with enhanced EMI protection for amplifiers, speakers, and professional audio gear

E. Why Choose Yicen Precision for Power Supply Housings?

Yicen Precision delivers exceptional value for power supply housings CNC machining through our comprehensive manufacturing expertise and customer-focused approach. Our rapid prototyping capabilities accelerate your development cycle, delivering functional housing prototypes within days for thermal testing, fit validation, and design iteration before committing to production tooling.

We offer flexible scalability from low-volume production for specialized applications through high-volume manufacturing for mass-market products, maintaining consistent quality and dimensional accuracy regardless of order size. Our engineering team provides expert DFM consultation specifically focused on power supply housing optimization, including thermal management design, ventilation placement, and manufacturing efficiency improvements that reduce costs while enhancing performance.

Complete material traceability with certified documentation supports regulatory compliance requirements including UL, CE, and FCC certifications. Our cost-effective solutions leverage efficient machining strategies, material optimization, and process refinement that deliver superior power supply housings at competitive pricing without compromising quality or performance specifications.

With dedicated project management, transparent communication throughout production, and reliable on-time delivery, we become your trusted manufacturing partner for bringing safe, efficient power supply solutions to market.