A. What is Prototyping in Consumer Electronics?

Prototyping in consumer electronics is the process of creating functional, physical representations of product designs for validation, testing, and refinement before mass production. These tangible prototypes include appearance models showcasing industrial design and aesthetics, functional prototypes demonstrating mechanical operation and assembly, engineering prototypes for durability and performance testing, pre-production prototypes validating manufacturing processes, and presentation prototypes for investor meetings and trade shows. Prototyping is essential across all consumer electronics categories including smartphones, tablets, wearables, audio equipment, smart home devices, gaming peripherals, and IoT products.

The primary purposes of prototyping include validating industrial design intent and ergonomics through physical interaction, testing mechanical functionality including button feel, hinge operation, and assembly sequences, verifying electronic component fitment and thermal management performance, conducting user experience studies and focus group evaluations, identifying manufacturing challenges and design for manufacturing improvements, demonstrating product concepts to stakeholders and potential customers, and accelerating development cycles through rapid iteration based on real-world feedback. Effective prototyping reduces development costs by catching design issues early, minimizes production risk by validating manufacturing approaches, and shortens time-to-market enabling faster product launches.

B. Key Technical Requirements

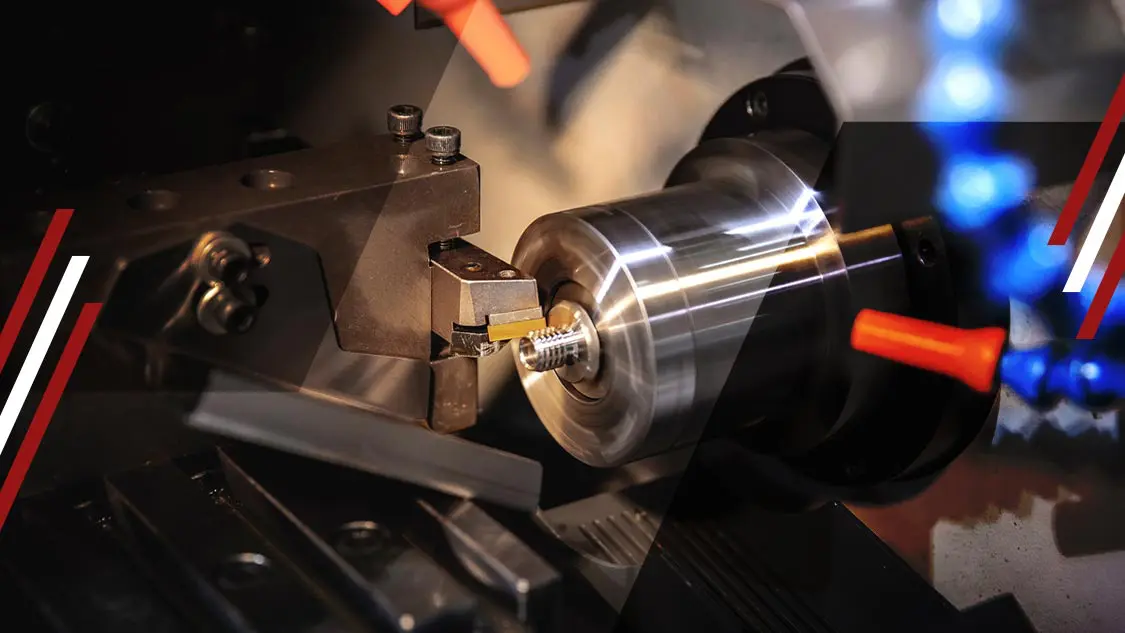

Prototyping CNC machining for consumer electronics requires balancing speed with accuracy and quality. Dimensional tolerances typically range from ±0.005″ to ±0.010″ for most features, with tighter tolerances of ±0.002″ to ±0.003″ achievable for critical functional surfaces when specified. While production parts may demand micron-level precision on every feature, prototypes focus precision on functionally critical dimensions enabling faster turnaround.

Material specifications match intended production materials enabling accurate representation of weight, thermal properties, structural performance, and aesthetic appearance. Surface finish requirements depend on prototype purpose—appearance models may require Ra values below 32 microinches with premium finishes like anodizing or polishing, while engineering prototypes may specify as-machined surfaces around Ra 63-125 microinches focused on functionality rather than cosmetics.

Assembly requirements include proper fitment between mating components with appropriate clearances, functional thread engagement for fasteners and adjustable features, and representative interface surfaces for electronics integration. Prototypes should demonstrate intended assembly sequences, identify potential interference issues, and validate ergonomic assumptions through physical interaction.

Flexibility is paramount in prototyping—designs often evolve during development requiring multiple iterations with progressive refinements. Efficient prototyping processes accommodate design changes quickly, provide feedback on manufacturability, and support rapid iteration cycles measured in days rather than weeks. Documentation requirements include dimensional inspection reports, material certifications, and photographic documentation supporting design reviews and stakeholder presentations.

C. Manufacturing Challenges & Solutions

Prototyping presents unique challenges distinct from production manufacturing including frequent design changes requiring flexible processes and minimal setup investment, small quantities (often 1-10 pieces) making dedicated tooling uneconomical, compressed timelines demanding rapid turnaround often within 3-7 days, material variety requiring quick changeovers between aluminum, steel, plastics, and specialty alloys, and balancing speed with quality to deliver meaningful validation without production-level cost.

Yicen Precision overcomes prototyping challenges through strategic approaches optimized for flexibility and responsiveness. Our 5-axis CNC machining centers enable efficient production of complex geometries in single setups, minimizing programming and setup time while maintaining accuracy. Modular fixturing systems accommodate diverse part geometries without custom fixture fabrication, reducing setup time from days to hours. Extensive CAM template libraries for common consumer electronics features like smartphone frames, buttons, and housings accelerate programming for new designs.

Dedicated prototyping production cells separate rapid-turnaround projects from high-volume production, preventing schedule conflicts and enabling focused attention on prototype-specific requirements. Cross-trained machinists experienced in consumer electronics applications provide valuable DFM feedback during initial review, identifying potential issues before machining begins and suggesting improvements enhancing manufacturability.

Material inventory stocked specifically for prototyping includes commonly requested alloys, thicknesses, and forms enabling immediate project starts without procurement delays. Established relationships with finishing vendors specializing in small-batch anodizing, powder coating, and plating ensure complete prototypes with production-representative finishes delivered on tight schedules.

Quality processes balance thoroughness with speed—critical dimensions undergo CMM verification while non-critical features receive coordinate measurement or hand inspection. Functional assembly validation ensures parts fit and operate as intended. Photographic documentation captures as-built condition supporting design reviews. Inspection reports identify any deviations from specifications with recommendations for design refinement.

D. Applications & Use Cases

Prototyping CNC machining enables rapid development across diverse consumer electronics applications:

- Smartphone and Tablet Development: Frame prototypes validating industrial design, camera module fitment, button tactile feedback, and assembly sequences for mobile device innovation

- Wearable Device Prototyping: Smartwatch cases, fitness tracker housings, and smart glasses frames enabling ergonomic testing, comfort validation, and user experience studies

- Audio Equipment Development: Headphone housings, speaker enclosures, amplifier chassis, and control knob prototypes for acoustic testing and aesthetic refinement

- Smart Home Product Prototypes: IoT device housings, thermostat covers, security camera enclosures, and hub chassis for functional validation and investor demonstrations

- Gaming Peripheral Development: Controller housings, keyboard frames, mouse prototypes, and joystick assemblies enabling ergonomic evaluation and mechanical testing

- Laptop and Desktop Prototyping: Computer chassis, keyboard decks, display bezels, and accessory housings for thermal validation and assembly verification

- New Product Category Exploration: Innovative device concepts, novel form factors, and emerging technology prototypes enabling market research and proof-of-concept demonstrations

E. Why Choose Yicen Precision for Prototyping?

Yicen Precision stands as your ideal prototyping partner through our specialized focus on rapid, high-quality prototype delivery for consumer electronics. Our fast turnaround times deliver most prototypes within 5-7 business days from design approval, with expedited 2-3 day services available for urgent timelines supporting critical milestones and investor meetings. We understand the pressure of product development schedules and prioritize responsiveness.

Our engineering support goes beyond simply machining parts—we provide comprehensive DFM consultation identifying potential manufacturing challenges, recommending design improvements, suggesting alternative approaches reducing costs, and validating assembly sequences. This collaborative approach catches issues early, accelerates iteration cycles, and improves final product manufacturability. Our team has extensive experience with consumer electronics requirements including tight tolerances, complex geometries, and premium finishes.

Flexible order quantities accommodate everything from single proof-of-concept models through bridge production runs of 100+ units supporting pilot manufacturing and market testing. No minimum order quantities restrict early-stage innovation. Material expertise spans the full range of production materials ensuring prototypes accurately represent final product characteristics including weight, thermal behavior, and structural performance.

Complete finishing capabilities including anodizing, powder coating, electroplating, polishing, and custom textures deliver prototypes with production-representative appearance enabling meaningful aesthetic evaluation and customer presentations. Quality documentation provides dimensional inspection reports, material certifications, and detailed photography supporting design reviews and regulatory submissions.

With transparent pricing quoted within 24 hours, dedicated project management providing regular updates, and commitment to your success throughout development, we become your trusted partner accelerating innovation from concept to market-ready products that succeed commercially.