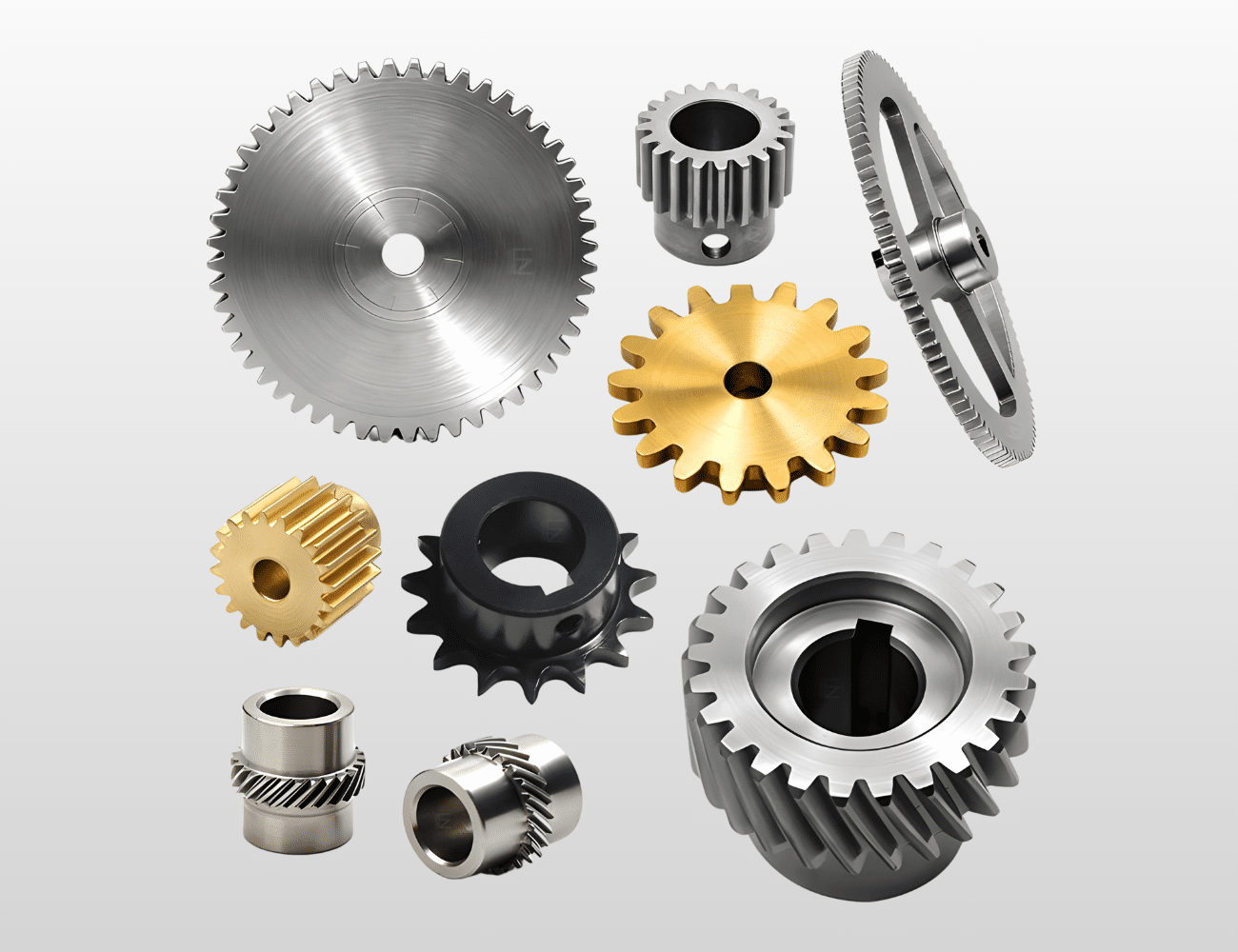

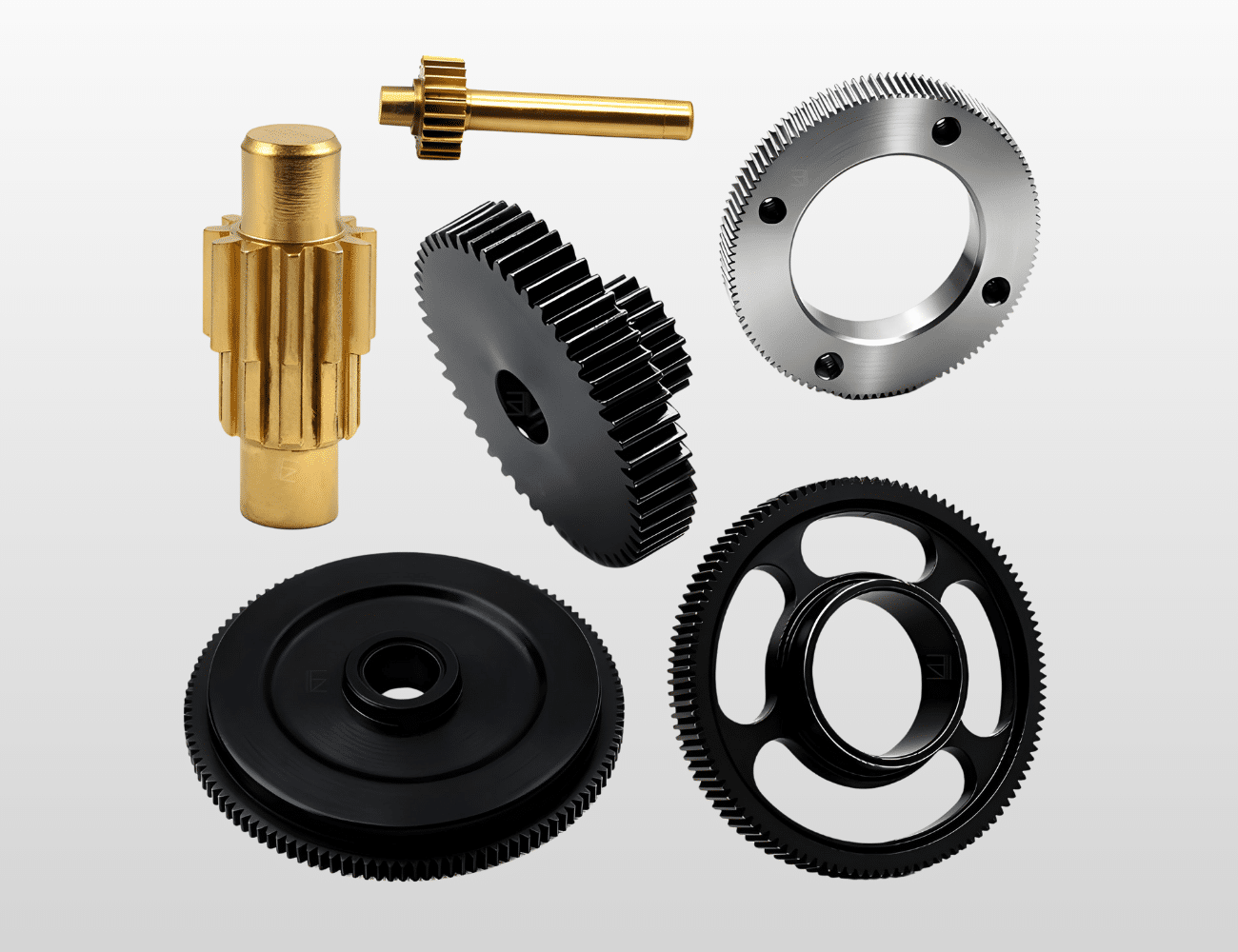

A. What are Gearboxes and Transmission Parts?

Gearboxes and transmission parts are precision-engineered mechanical components that transmit rotational power and torque between different sections of industrial machinery systems. These assemblies include gear housings, transmission shafts, bearing retainers, clutch plates, planetary gear carriers, and differential cases. They are essential in heavy machinery, manufacturing equipment, agricultural machinery, construction vehicles, and automated production systems. Their primary function is to modify speed ratios, increase torque output, change rotational direction, and distribute power efficiently across multiple operational axes while maintaining synchronization under extreme mechanical stress.

B. Key Technical Requirements

Precision gearboxes and transmission parts demand exceptionally tight tolerances, typically ranging from ±0.0005″ to ±0.001″ for critical mating surfaces and gear mounting interfaces. Material specifications require high-strength alloys such as 4140 steel, 17-4 PH stainless steel, aluminum 7075, and bronze alloys with specific hardness ratings (HRC 28-62 depending on application). Surface finish requirements vary from 32 Ra for housing exteriors to 8-16 Ra for precision bearing seats and sealing surfaces.

These components must withstand continuous cyclic loading, impact forces, and vibration without deformation or fatigue failure. Stress concentration areas require careful fillet radii and geometric optimization. Temperature resistance is critical, with operating ranges from -40°F to 400°F depending on application. Environmental considerations include resistance to hydraulic fluids, lubricants, moisture, and contaminants while maintaining dimensional stability throughout the operational lifecycle.

C. Manufacturing Challenges & Solutions

Machining gearboxes and transmission parts presents significant challenges including complex internal cavities, deep pockets with limited tool access, and maintaining concentricity across multiple bearing bores. Hardened materials create excessive tool wear and require specialized cutting strategies. Thin-walled sections are prone to deflection during machining, causing dimensional inaccuracies. Heat-treated components may experience distortion requiring post-hardening precision grinding operations.

Yicen Precision overcomes these challenges through advanced 5-axis CNC machining that provides simultaneous multi-face access and optimal tool angles for deep cavity work. We utilize CAM software with adaptive toolpath strategies that minimize cutting forces on thin walls while maintaining aggressive material removal rates on bulk sections. Our precision inspection protocols include CMM verification of critical dimensions, surface finish analysis, and hardness testing at multiple locations.

For complex transmission assemblies, we employ high-pressure coolant delivery systems and carbide tooling with specialized coatings to extend tool life when machining hardened steels. Dimensional verification occurs at multiple production stages using in-process gauging and final CMM reporting with full traceability documentation.

D. Applications & Use Cases

Industrial machinery gearboxes and transmission parts manufactured by Yicen Precision serve diverse applications:

- Heavy Manufacturing Equipment – CNC machines, presses, and automated assembly systems

- Agricultural Machinery – Tractors, harvesters, and irrigation system drives

- Construction Equipment – Excavators, bulldozers, and material handling systems

- Mining Machinery – Crushers, conveyors, and drilling equipment powertrains

- Material Handling Systems – Cranes, hoists, and automated warehouse robotics

- Industrial Robotics – Precision actuators and multi-axis positioning systems

- Power Generation Equipment – Wind turbines, hydroelectric systems, and generator assemblies

- Marine and Off-Shore Equipment – Winches, propulsion systems, and deck machinery

E. Why Choose Yicen Precision for Gearboxes and Transmission Parts?

Yicen Precision offers unmatched expertise in manufacturing complex gearboxes and transmission parts with guaranteed dimensional accuracy and material integrity. Our rapid turnaround capabilities support both prototype development and high-volume production runs without sacrificing quality standards. We provide comprehensive engineering support including DFM consultation to optimize designs for manufacturability, cost reduction, and performance enhancement.

Our material traceability systems ensure complete documentation from raw material certification through final inspection reports, meeting the most stringent industrial standards. We maintain strategic inventory partnerships enabling cost-effective material sourcing for both standard and exotic alloys. Our scalable production capacity accommodates orders from single prototypes to thousands of production units with consistent quality across every batch. With decades of gearbox manufacturing experience, we understand the critical nature of power transmission components and deliver solutions that exceed expectations.

Contact us today for a custom quote on your gearboxes and transmission parts CNC machining project.