A. What are Industrial Motors and Components?

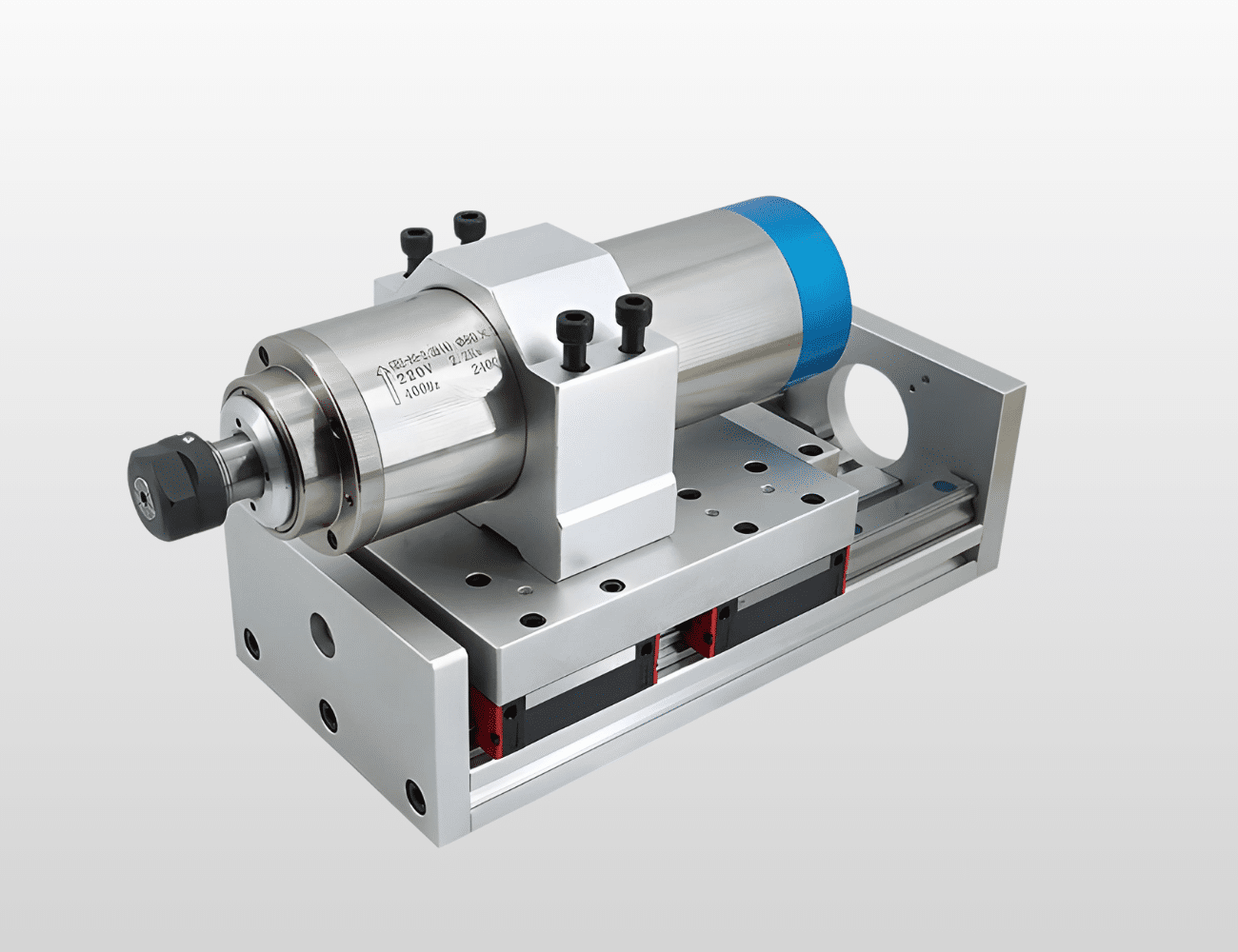

Industrial motors and components are precision-engineered assemblies that convert electrical energy into controlled mechanical motion for powering industrial machinery systems. These include motor housings (frames), end bells (end shields), rotor cores, stator housings, bearing caps, terminal boxes, cooling fan shrouds, and mounting brackets. They are utilized across manufacturing automation, HVAC systems, material handling equipment, pumps, compressors, machine tools, and process control systems. Their essential function is to provide structural support for electromagnetic components, maintain precise air gaps between rotor and stator, ensure proper bearing alignment, facilitate heat dissipation, and protect internal electrical components while operating under continuous loads, variable speeds, and challenging environmental conditions.

B. Key Technical Requirements

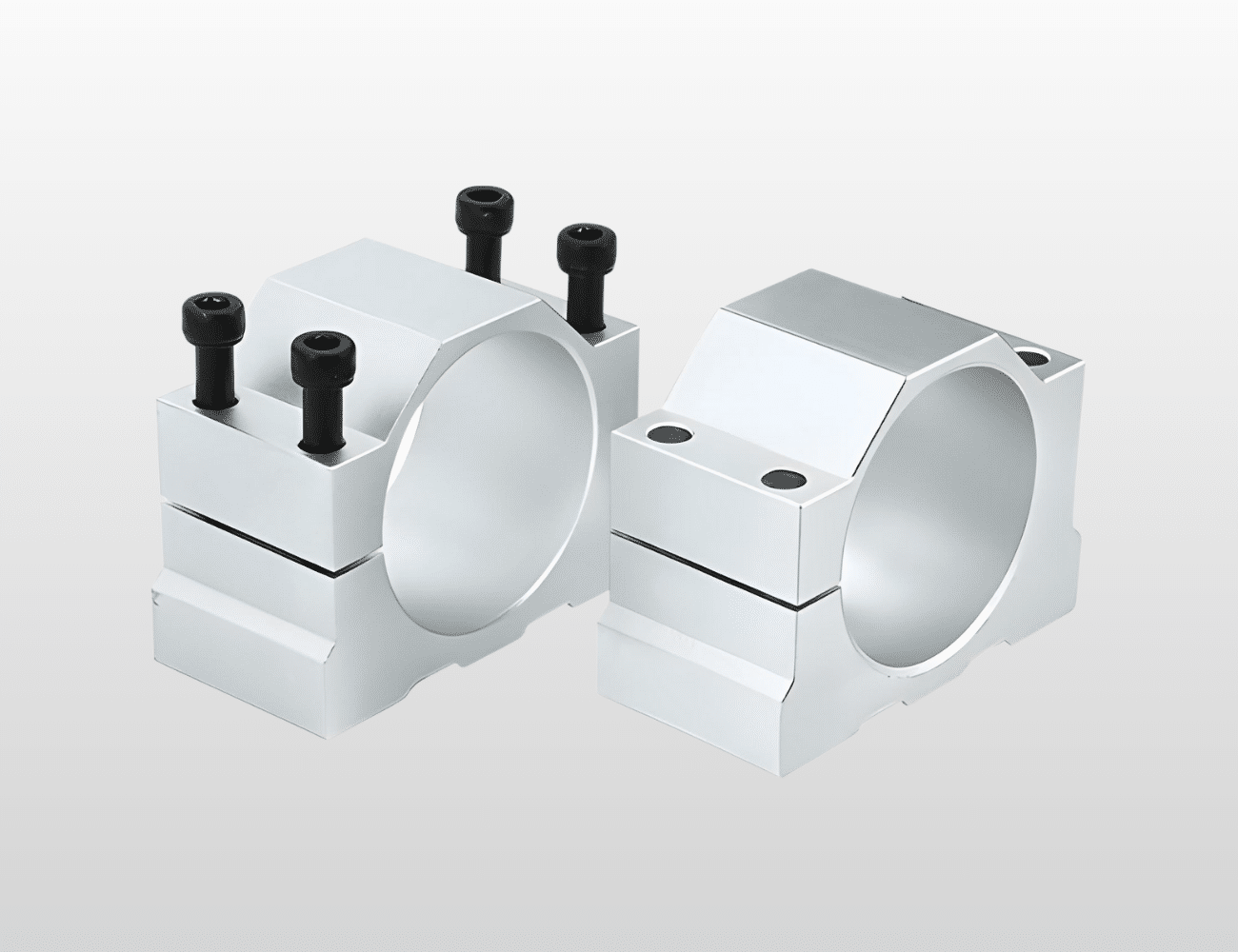

Precision industrial motors and components require extremely tight tolerances with bearing bore specifications of ±0.0002″ to ±0.0005″ to ensure proper press fits and prevent bearing creep. Concentricity between bearing seats and mounting surfaces must be maintained within 0.0003″ to 0.0005″ TIR to eliminate shaft misalignment and vibration. Material specifications include aluminum 356-T6 and 6061-T6 for lightweight motor housings, cast iron grades for thermal stability and electromagnetic shielding, and steel alloys for high-strength structural components.

Surface finish requirements vary from 32-63 Ra for external housing surfaces to 16-32 Ra for bearing mounting surfaces and sealing faces. Flatness specifications for mounting surfaces and end bell mating faces must be within 0.002″ to prevent gasket leakage and ensure proper motor assembly. Perpendicularity between bearing bores and mounting surfaces is critical, typically specified within 0.001″ to prevent shaft deflection and premature bearing wear.

These components must accommodate thermal expansion during motor operation with temperature ranges from -40°F to 350°F depending on motor class ratings. Electromagnetic compatibility requires proper material selection to prevent magnetic interference and eddy current losses. Environmental resistance includes protection against moisture ingress (IP ratings up to IP67), vibration resistance per MIL-STD-810, and chemical resistance to industrial oils, coolants, and cleaning agents while maintaining structural integrity throughout the motor’s operational lifespan.

C. Manufacturing Challenges & Solutions

Machining industrial motors and components presents unique challenges including maintaining concentricity across multiple bearing bores in cast housings with inherent material inconsistencies. Thin-walled motor housings require careful machining strategies to prevent distortion and chatter. Complex cooling fin geometries and ventilation passages demand multi-axis access and specialized tooling. Cast components may contain porosity that affects surface finish and dimensional stability. Thread accuracy for mounting holes and conduit entries requires precision across numerous features.

Yicen Precision addresses these challenges through advanced 5-axis CNC machining that enables simultaneous machining of multiple features in single setups, ensuring perfect concentricity between bearing bores regardless of housing configuration. We employ specialized boring heads with fine adjustment capabilities achieving bearing bore tolerances within ±0.0002″. For cast components, we utilize carbide tooling with optimized cutting parameters that accommodate material hardness variations while maintaining consistent surface finishes.

Our precision fixturing systems incorporate soft jaws and vacuum clamping for thin-walled housings, minimizing distortion during machining operations. For complex ventilation features, we utilize high-speed machining with adaptive toolpaths that maintain optimal chip evacuation. Every motor housing undergoes comprehensive CMM inspection verifying concentricity, perpendicularity, flatness, and all critical dimensions. Dynamic balancing services are available for rotor components, ensuring vibration-free operation at rated speeds. Material certifications and dimensional reports accompany all shipments.

D. Applications & Use Cases

Industrial motors and components manufactured by Yicen Precision serve critical applications across diverse sectors:

- Manufacturing Automation – Servo motor housings for robotic systems and CNC machine tools

- HVAC Systems – Blower motor housings and fan assemblies for commercial climate control

- Material Handling Equipment – Conveyor drive motor components and hoist motor assemblies

- Pump and Compressor Systems – Motor-pump integrated housings and close-coupled assemblies

- Industrial Fans and Blowers – Heavy-duty motor frames for ventilation and exhaust systems

- Process Equipment – Explosion-proof motor housings for hazardous location applications

- Food and Beverage Processing – Washdown-rated stainless steel motor enclosures

- Medical Equipment – Precision motor components for imaging systems and surgical instruments

E. Why Choose Yicen Precision for Industrial Motors and Components?

Yicen Precision delivers specialized expertise in manufacturing industrial motors and components with guaranteed concentricity, dimensional precision, and surface finish quality that ensures optimal motor performance and longevity. Our rapid prototyping capabilities support design validation and functional testing before production commitments, reducing development risk and time-to-market. We provide comprehensive engineering collaboration including thermal analysis recommendations, material selection guidance, and DFM consultation to optimize motor efficiency and reduce manufacturing costs.

Our quality systems ensure complete traceability with material certifications, dimensional inspection reports, and concentricity verification documentation for every component. We maintain strategic partnerships with aluminum foundries and steel suppliers enabling access to premium materials at competitive pricing. Our production flexibility accommodates orders from single prototype units to high-volume production exceeding 25,000 units annually with identical quality standards maintained throughout. With decades of electromechanical component manufacturing experience and specialized motor industry knowledge, we understand the critical importance of precision alignment and deliver industrial motors and components that exceed performance expectations.

Request a detailed engineering consultation for your industrial motors and components CNC machining requirements.