In the medical industry, precision isn’t optional it’s life-critical. From surgical tools and diagnostic equipment to implantable components and wearable devices, every part must meet the highest standards of accuracy, safety, and reliability.

At Yicen MPrecision, we specialize in high-precision CNC machining for medical devices. We work with OEMs, startups, and medtech innovators to deliver mission-critical components that meet strict regulatory and performance requirements.

Why CNC Machining Is Vital in Medical Manufacturing

Medical components often require:

- Ultra-tight tolerances for flawless operation

- Biocompatible materials for patient safety

- Smooth finishes to prevent contamination

- Traceability to meet regulatory standards

- Consistent quality across production runs

Our advanced CNC capabilities ensure we meet these demands—whether for a single prototype or a high-volume production batch.

Medical Device Components We Machine

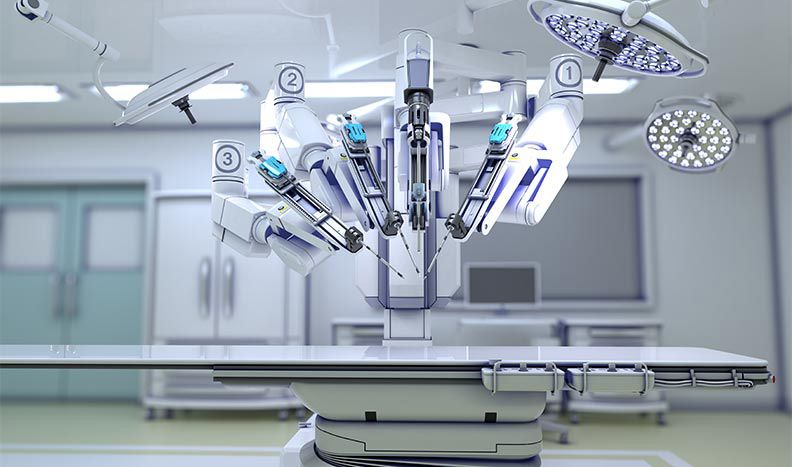

1. Surgical Instrumentation

We produce durable, corrosion-resistant tools used in operating rooms and outpatient procedures, including:

- Forceps, clamps, and scissors

- Orthopedic drill guides and reamers

- Custom endoscopic tools

- Robotic surgery components

All parts are machined to surgical-grade precision with polished finishes or coatings as needed.

2. Implantable Device Components

We machine metal and polymer components used in permanent and temporary implants, such as:

- Bone plates and screws

- Spinal implants

- Dental abutments

- Catheter tips and housings

We work with titanium, PEEK, and surgical-grade stainless steels all known for their biocompatibility.

3. Diagnostic Equipment Parts

Modern imaging and diagnostic tools rely on intricate mechanical parts for movement, calibration, and signal processing. We provide:

- Precision brackets and mounts

- Sensor housings and alignment frames

- Internal actuator components

- Chassis parts for imaging machines

Tight tolerance and stable materials ensure accuracy in every scan or measurement.

4. Wearable and Portable Medical Devices

As medtech becomes more mobile, we support developers with:

- Lightweight enclosures and casings

- Connector housings and interface panels

- Heat sinks for electronics

- Clip-on and strap mechanisms

We offer machining for medical-grade plastics and metals, and finishes suitable for skin contact and daily use.

From Development to Production: Our Process

At Yicen Precision, we understand the medical device lifecycle from rapid prototyping and regulatory testing to full-scale production. We provide:

Rapid Prototyping

Need a testable prototype or clinical trial sample? We deliver functional parts in days with precision machining and fast-turn setups.

Design for Manufacturability (DFM)

Our engineers work with your team to refine designs, reduce machining complexity, and ensure parts can be consistently reproduced.

Regulatory-Ready Production

We maintain strict process controls, documentation, and material traceability to help you meet ISO and FDA requirements.

Scalable CNC Manufacturing

When you’re ready to scale, we can ramp up production to thousands of units without compromising quality, finish, or traceability.

Applications We Support in the Medical Industry

We work with companies developing and manufacturing:

- Surgical and orthopedic tools

- Diagnostic imaging equipment

- Hospital-grade monitoring systems

- Dental devices and implants

- Wearable health tech and biosensors

- Robotic surgery subsystems

- Catheter and IV delivery systems

If it needs to be precise, sterile, and strong we’ve likely machined it.

Partner with Yicen Precision to ensure your medical devices are built with unmatched precision, reliability, and care.