We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

Discover the precision and reliability of Myted manufacturing solutions for the new energy industry. Reach out today to discuss your project and request a customized quote.

The transition to clean and renewable energy requires components that can withstand extreme conditions and deliver consistent performance. Yicen Precision plays a crucial role in this mission by providing CNC-machined parts designed for wind, solar, and energy storage systems. From turbine hubs to battery casings, our machining expertise ensures strength, durability, and flawless integration, helping energy innovators push forward with confidence.

Every new energy project comes with unique challenges and Yicen meets them with custom-engineered CNC solutions. Our team collaborates with energy pioneers to develop specialized parts that improve system efficiency and long-term reliability. Certified for quality and safety, we deliver components that not only meet but exceed the rigorous standards of the energy sector. By turning complex designs into precision reality, Yicen empowers companies to build a greener, more sustainable future.

We engineer high-performance CNC components tailored for renewable energy systems, from wind and solar to advanced battery technologies, built for durability and sustainability.

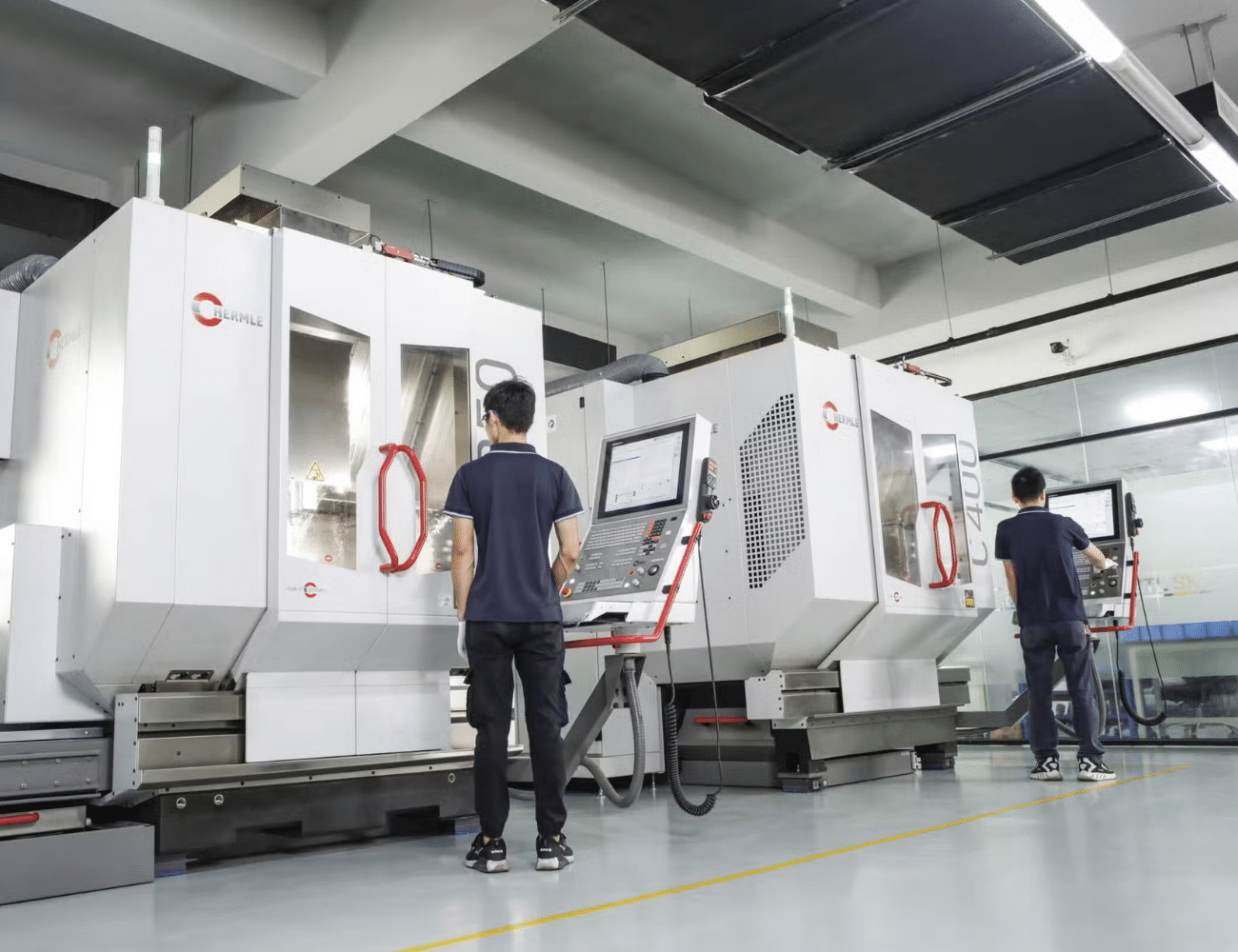

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

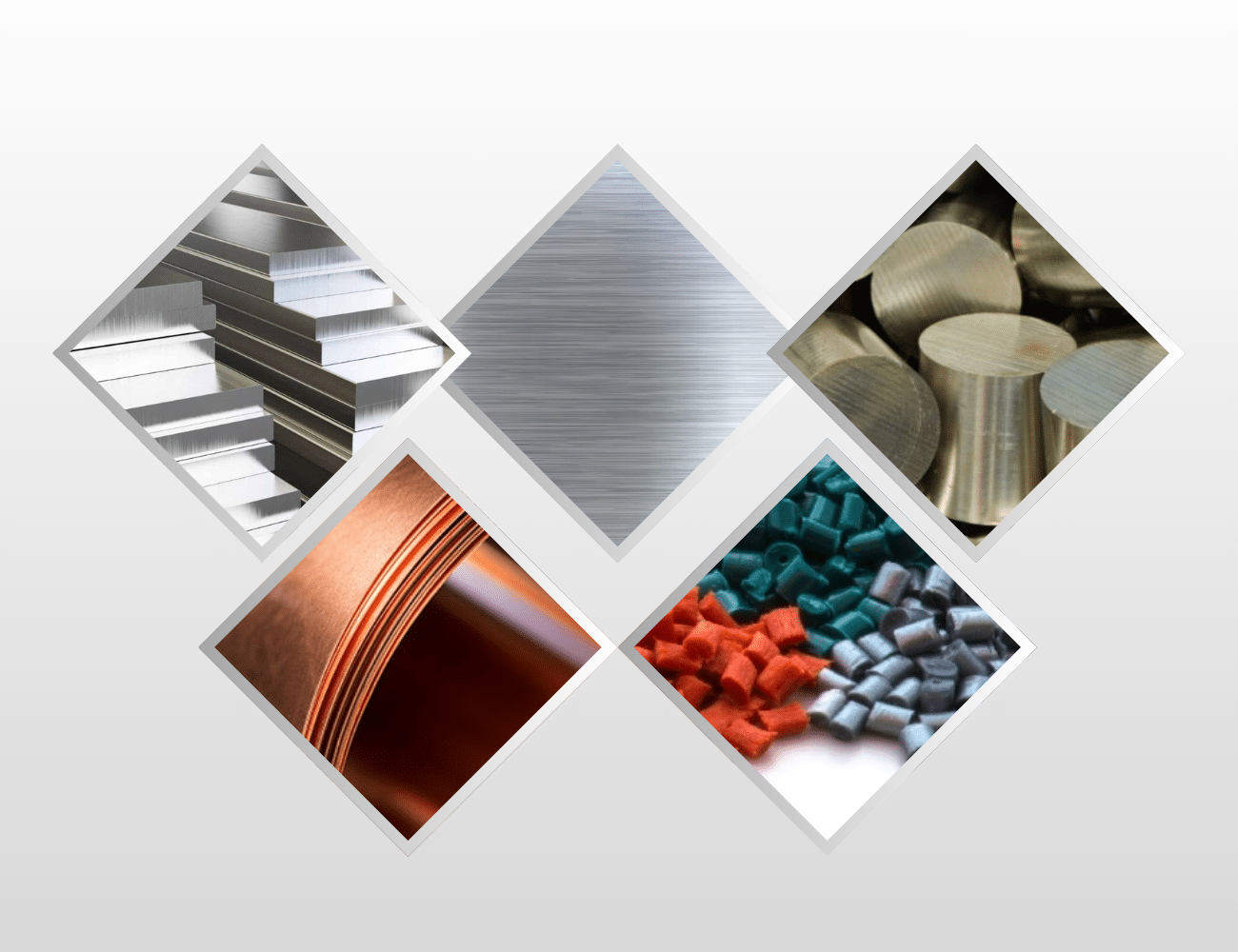

Yicen Precision offers a wide selection of durable metals and advanced composites to meet the structural, thermal, and chemical resistance demands of wind, solar, and energy storage systems.

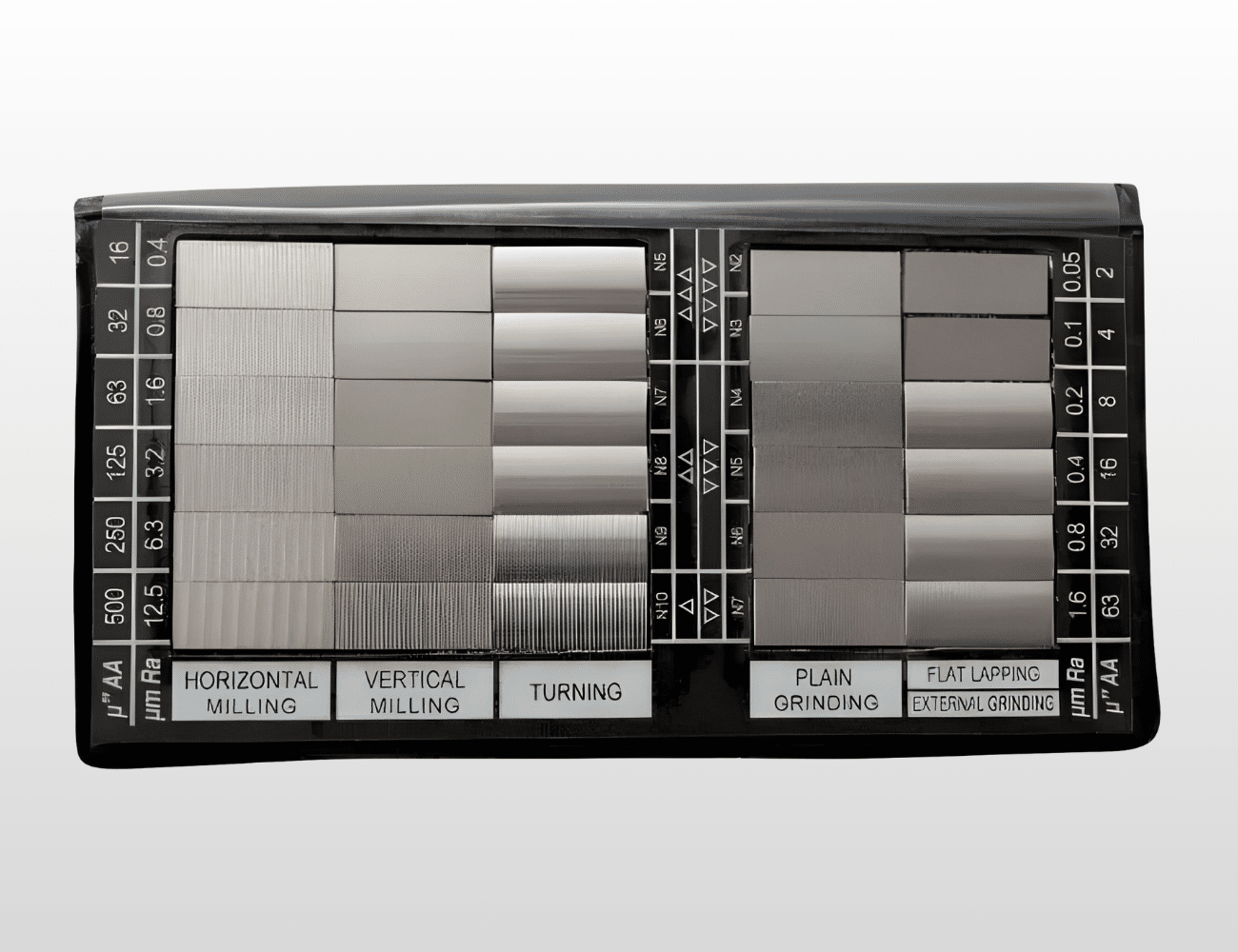

For renewable energy systems, surface finishes must ensure corrosion resistance, wear protection, and long-term reliability in harsh environments. Yicen Precision applies protective and functional coatings that extend the lifespan of components used in wind, solar, and battery applications.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

The world is entering a new era of energy. With the demand for clean, renewable power sources such as wind, solar, and hydrogen fuel cells growing at record speed, the new energy industry is at the center of this transformation. To meet rising global expectations, manufacturers require components that can withstand extreme environmental conditions while delivering consistent efficiency. This is where CNC machining steps in as a game-changing technology.

Unlike traditional manufacturing processes, CNC (Computer Numerical Control) machining delivers the precision, durability, and scalability required for renewable energy technologies. New energy systems often involve large-scale, high-stress applications, such as wind turbines, solar mounting systems, and energy storage units, where reliability directly impacts efficiency and lifespan.

Key benefits of CNC machining for the new energy sector include:

At Yicen Precision, we understand the challenges energy innovators face—extreme operating environments, the need for high efficiency, and the pressure to deliver sustainable solutions at scale. Our advanced CNC machining services are designed to help businesses meet these demands with confidence.

Here’s how we contribute to the industry’s success:

The revolution in new energy is only beginning, and the companies leading the way require reliable partners to turn vision into reality. By combining advanced CNC machining technology with decades of expertise, Yicen Precision empowers innovators to build cleaner, stronger, and more efficient energy systems. Together, we’re not just producing parts, we’re fueling the future of global sustainability.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

How does Yicen Precision help with rapid innovation in new energy?

We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

Are CNC components adaptable for hybrid energy systems?

CNC machining allows the customization of parts for hybrid setups like solar-plus-storage, ensuring compatibility across diverse energy technologies.

How does CNC machining reduce maintenance costs in renewable systems?

By producing durable, corrosion-resistant components, CNC machining minimizes wear and tear, lowering the frequency and cost of repairs in wind and solar systems.

Can CNC machining support hydrogen and fuel cell technologies?

Yes, CNC is ideal for producing precision flow plates, manifolds, and connectors in hydrogen fuel cells, where accuracy directly affects energy output and safety.