We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

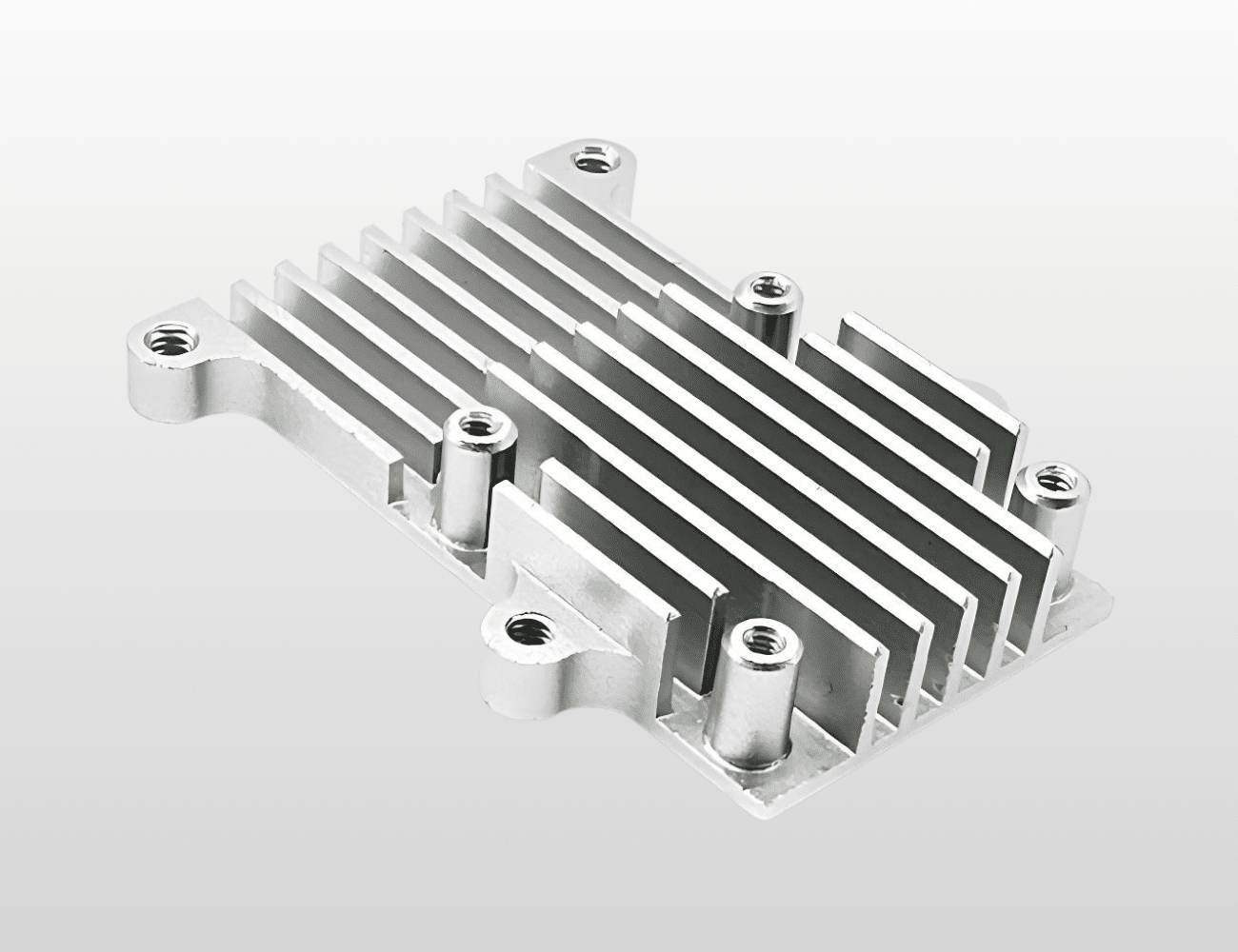

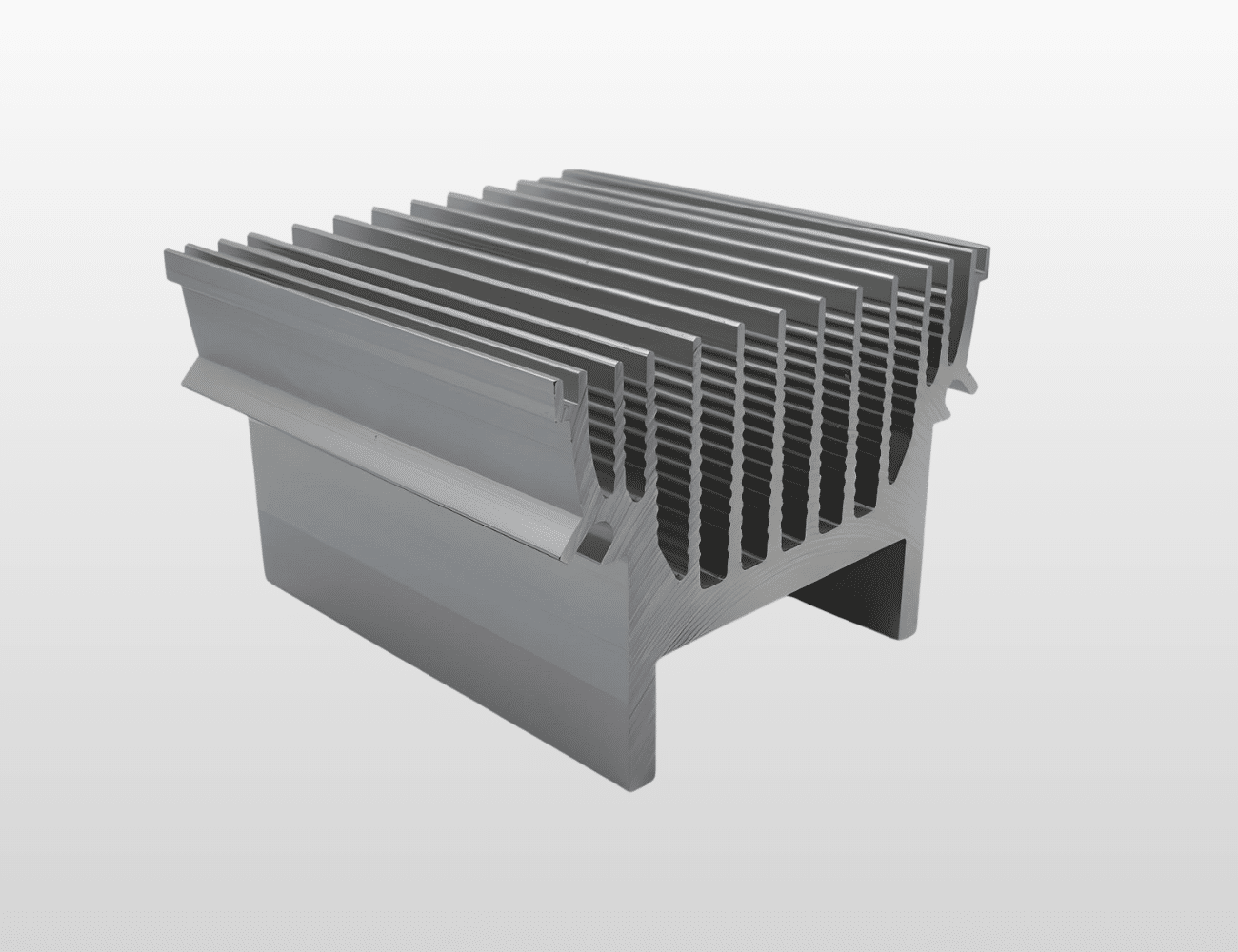

High-performance cooling system components machined to exact specifications for optimal thermal management in renewable energy applications. Our precision CNC capabilities deliver heat exchangers, manifolds, and thermal interface components with intricate flow channels that maximize heat transfer efficiency and system reliability. Get custom thermal solutions engineered for your specific requirements today.

The transition to clean and renewable energy requires components that can withstand extreme conditions and deliver consistent performance. Yicen Precision plays a crucial role in this mission by providing CNC-machined parts designed for wind, solar, and energy storage systems. From turbine hubs to battery casings, our machining expertise ensures strength, durability, and flawless integration, helping energy innovators push forward with confidence.

Cooling system components form the critical thermal management infrastructure for renewable energy equipment, dissipating heat from power electronics, generators, battery systems, and inverters to maintain optimal operating temperatures and prevent performance degradation or thermal failures. These components must achieve precise flow distribution, maximize heat transfer surface area, and withstand pressure cycling while resisting corrosion from coolant exposure over extended service lives.

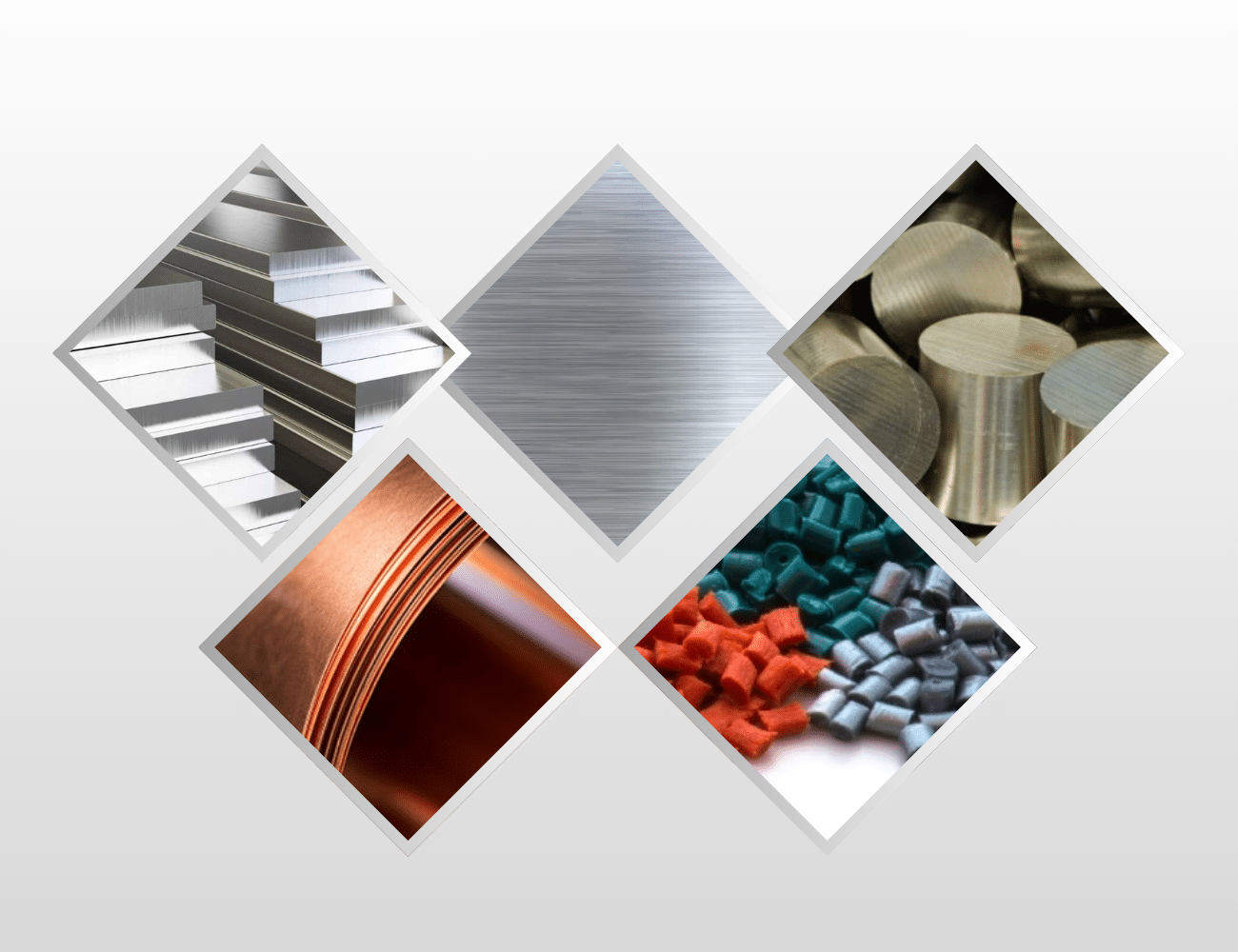

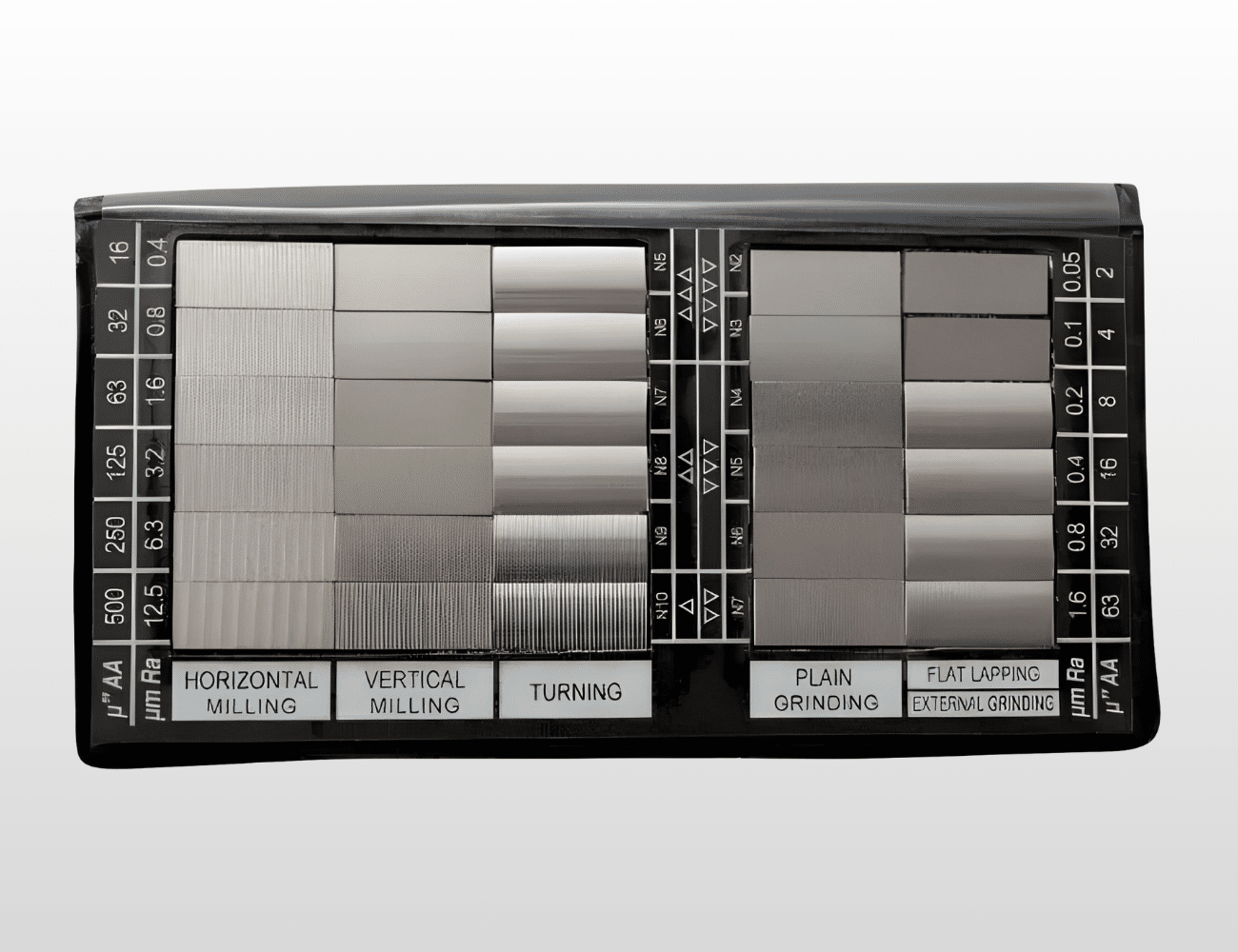

Yicen Precision delivers advanced cooling system components CNC machining through our 3-axis, 4-axis, and 5-axis machining centers optimized for producing complex internal geometries including serpentine cooling channels, turbulence-enhancing features, and manifold distribution networks. We machine cooling components from aluminum alloys 6061-T6 and 6063-T5, copper alloys C110 and C122, stainless steel 304 and 316, and titanium for specialized applications, maintaining channel dimension tolerances within ±0.005″ and surface finish specifications to 32 Ra for optimal fluid flow characteristics. Our ISO 9001-compliant manufacturing processes incorporate pressure testing, flow verification, and leak detection to ensure every cooling system component meets demanding performance standards for thermal efficiency, pressure integrity, and corrosion resistance in wind turbines, solar inverters, battery energy storage systems, and power conversion equipment.

We engineer high-performance CNC components tailored for renewable energy systems, from wind and solar to advanced battery technologies, built for durability and sustainability.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

Yicen Precision offers a wide selection of durable metals and advanced composites to meet the structural, thermal, and chemical resistance demands of wind, solar, and energy storage systems.

For renewable energy systems, surface finishes must ensure corrosion resistance, wear protection, and long-term reliability in harsh environments. Yicen Precision applies protective and functional coatings that extend the lifespan of components used in wind, solar, and battery applications.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

Cooling system components are engineered thermal management devices including heat exchangers, cold plates, manifolds, coolant distribution blocks, and thermal interface assemblies that transfer heat from renewable energy equipment to cooling media such as air, water, or glycol mixtures. These components function by maximizing surface area contact between heat sources and coolant flow while optimizing fluid velocity and turbulence to enhance convective heat transfer coefficients. They are essential in wind turbine nacelle cooling systems, solar inverter thermal management, battery energy storage temperature regulation, power electronics cooling for grid-tied systems, and hydrogen electrolyzer thermal control. The component’s thermal performance directly influences equipment efficiency, with every 10°C reduction in operating temperature typically improving semiconductor reliability by 50% and extending service life significantly.

Cooling system components CNC machining requires maintaining flow channel dimensional tolerances of ±0.005″ to ensure predictable pressure drop and flow distribution characteristics, with surface finish specifications of 32-63 Ra on internal passages to minimize turbulent friction losses. Material specifications demand thermal conductivity exceeding 200 W/m·K for aluminum or 385 W/m·K for copper alloys to facilitate efficient heat transfer, with corrosion resistance verified through compatibility testing with ethylene glycol, propylene glycol, and water-based coolants per ASTM D1384. Pressure integrity requirements typically specify burst pressures exceeding 300 psi for automotive-grade systems or 150 psi for facility cooling applications, with leak rates below 1×10⁻⁶ mbar·L/s on helium testing. Flatness tolerances of ±0.003″ per inch on mating surfaces ensure proper gasket compression and thermal interface contact, while port thread tolerances follow 6g thread class for reliable fitting assembly. Thermal cycling resistance across temperature ranges from -40°C to 125°C without dimensional distortion or joint failure is mandatory for outdoor renewable energy installations.

Producing cooling system components presents significant challenges including machining deep, narrow cooling channels with high aspect ratios while maintaining dimensional control, creating complex internal geometries that maximize heat transfer surface area within compact envelopes, and achieving leak-proof joints between multiple passages intersecting at various angles. The requirement for thin-wall sections to minimize thermal resistance while maintaining structural integrity under pressure cycling demands careful material removal strategies. Cooling component manufacturing also faces difficulties in removing chips from deep internal channels, maintaining surface finish uniformity in areas with limited tool access, and achieving the flatness required for effective thermal interface contact across large base surfaces.

Yicen Precision addresses these challenges through strategic application of 5-axis machining that enables efficient access to complex internal features from multiple angles without repositioning, reducing setup errors and improving dimensional consistency. Our advanced CAM programming incorporates high-efficiency milling strategies with optimized tool engagement that minimize cutting forces on thin-wall sections, preventing deflection-induced dimensional errors. For deep channel machining, we utilize extended-reach tooling with through-spindle coolant delivery that ensures effective chip evacuation and thermal control during cutting operations. Climate-controlled manufacturing facilities maintain temperature stability within ±2°F, preventing thermal expansion variations during precision machining of large cold plates and heat exchangers. Quality control protocols include helium leak testing verifying hermetic integrity to aerospace standards, pressure testing to 1.5x working pressure, flow testing validating hydraulic resistance matches design specifications, and CMM verification of all critical dimensions including channel depths, port locations, and mounting surface flatness. We employ specialized bonding and welding processes including vacuum brazing, friction stir welding, and diffusion bonding to create sealed cooling passages, with each process selected based on material, geometry, and performance requirements.

Cooling system components CNC machining serves critical thermal management applications across renewable energy sectors:

Our specialized expertise in precision cooling component manufacturing combines advanced machining capabilities with deep understanding of thermal management principles and fluid dynamics. We maintain production capacity ranging from small-format power electronics cold plates to large heat exchanger assemblies exceeding 36 inches in length, with machining capabilities accommodating complex multi-port manifolds and intricate internal channel geometries. Fast turnaround times of 2-4 weeks for production quantities support aggressive product development schedules, while our rapid prototyping services deliver functional components within 5-10 business days for thermal performance validation and flow testing. Our engineering team provides comprehensive DFM consultation and thermal analysis support, optimizing channel configurations to enhance heat transfer coefficients by 15-25% through strategic turbulator placement, fin geometry optimization, and flow distribution modeling using CFD simulation. We collaborate on material selection, balancing thermal conductivity requirements with corrosion resistance needs, weight constraints, and cost targets specific to renewable energy applications. Complete documentation accompanies every shipment, including material certifications with thermal conductivity data, dimensional inspection reports, pressure test results, leak test verification, and flow test data when specified. We deliver cost-effective solutions through efficient manufacturing processes that minimize machining time while maintaining the precision and surface finish critical to thermal performance, strategic material procurement that reduces raw material costs by 10-15%, and quality systems ensuring zero-defect pressure integrity—providing reliable cooling components that protect your valuable renewable energy equipment, maximize operational efficiency, and deliver consistent performance across demanding thermal cycles and extended service lives in challenging environmental conditions.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

How does Yicen Precision help with rapid innovation in new energy?

We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

Are CNC components adaptable for hybrid energy systems?

CNC machining allows the customization of parts for hybrid setups like solar-plus-storage, ensuring compatibility across diverse energy technologies.

How does CNC machining reduce maintenance costs in renewable systems?

By producing durable, corrosion-resistant components, CNC machining minimizes wear and tear, lowering the frequency and cost of repairs in wind and solar systems.

Can CNC machining support hydrogen and fuel cell technologies?

Yes, CNC is ideal for producing precision flow plates, manifolds, and connectors in hydrogen fuel cells, where accuracy directly affects energy output and safety.