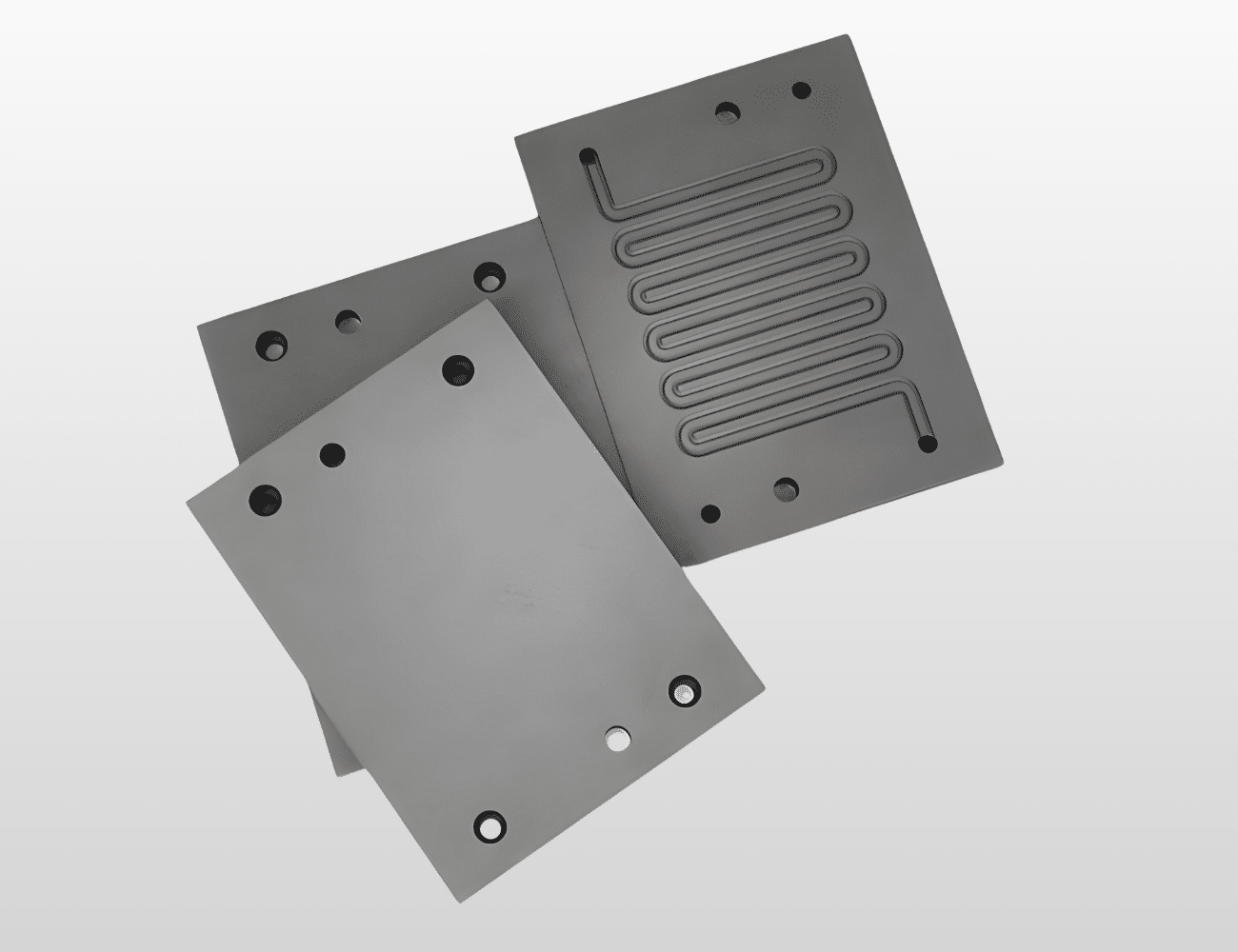

A. What are Hydrogen Fuel Cell Plates?

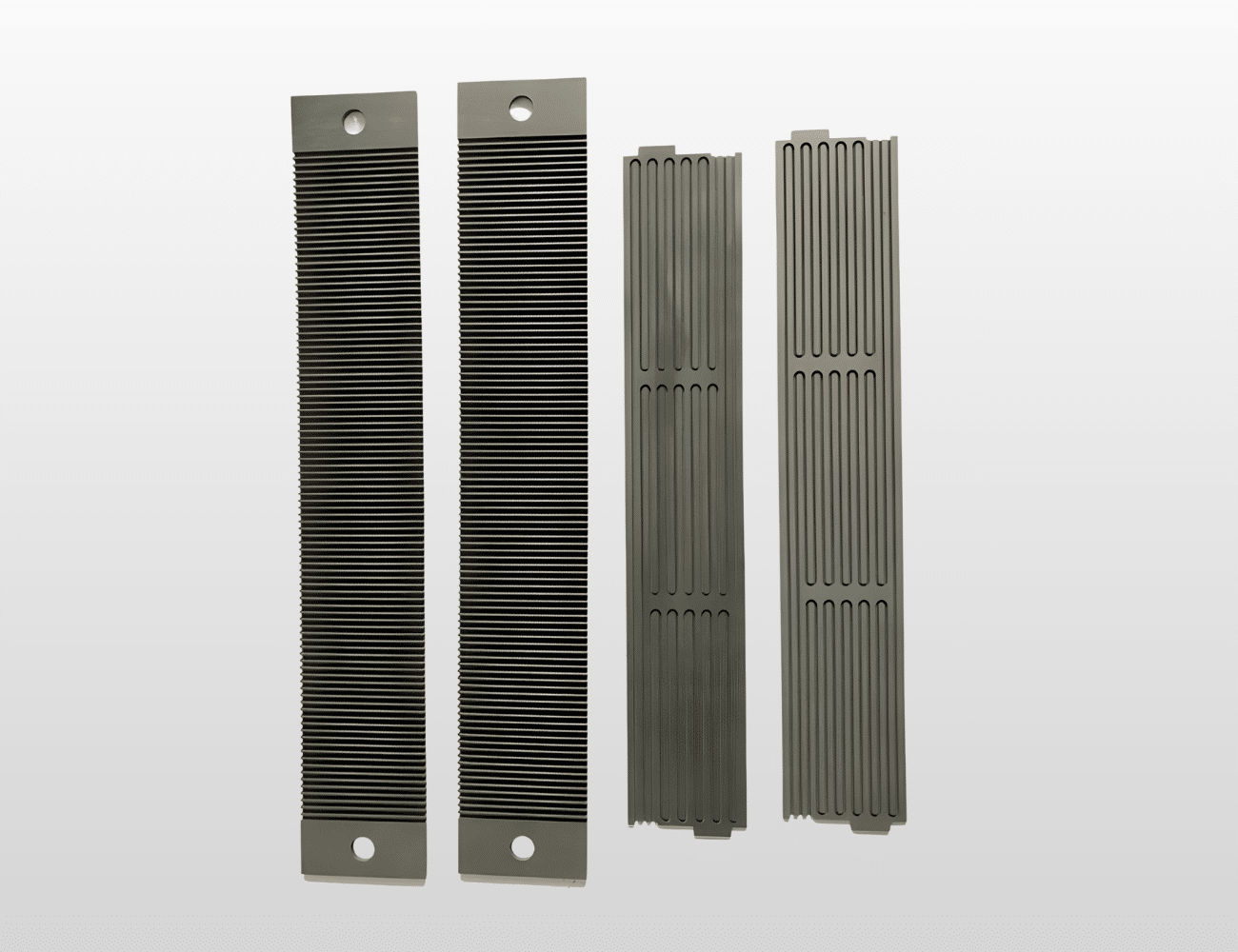

Hydrogen fuel cell plates, commonly known as bipolar plates or flow-field plates, are essential components in proton exchange membrane (PEM) fuel cells and solid oxide fuel cells (SOFC). These plates serve multiple critical functions: distributing hydrogen and oxygen gases uniformly across the membrane electrode assembly, conducting electrical current between individual cells, and managing heat and water within the fuel cell stack. Fuel cell plates feature intricate flow-field patterns with channels and ribs that optimize gas distribution while maintaining structural integrity. Used extensively in automotive fuel cells, stationary power generation systems, and portable energy devices, these plates directly impact fuel cell efficiency, power density, and operational longevity in renewable energy applications.

B. Key Technical Requirements

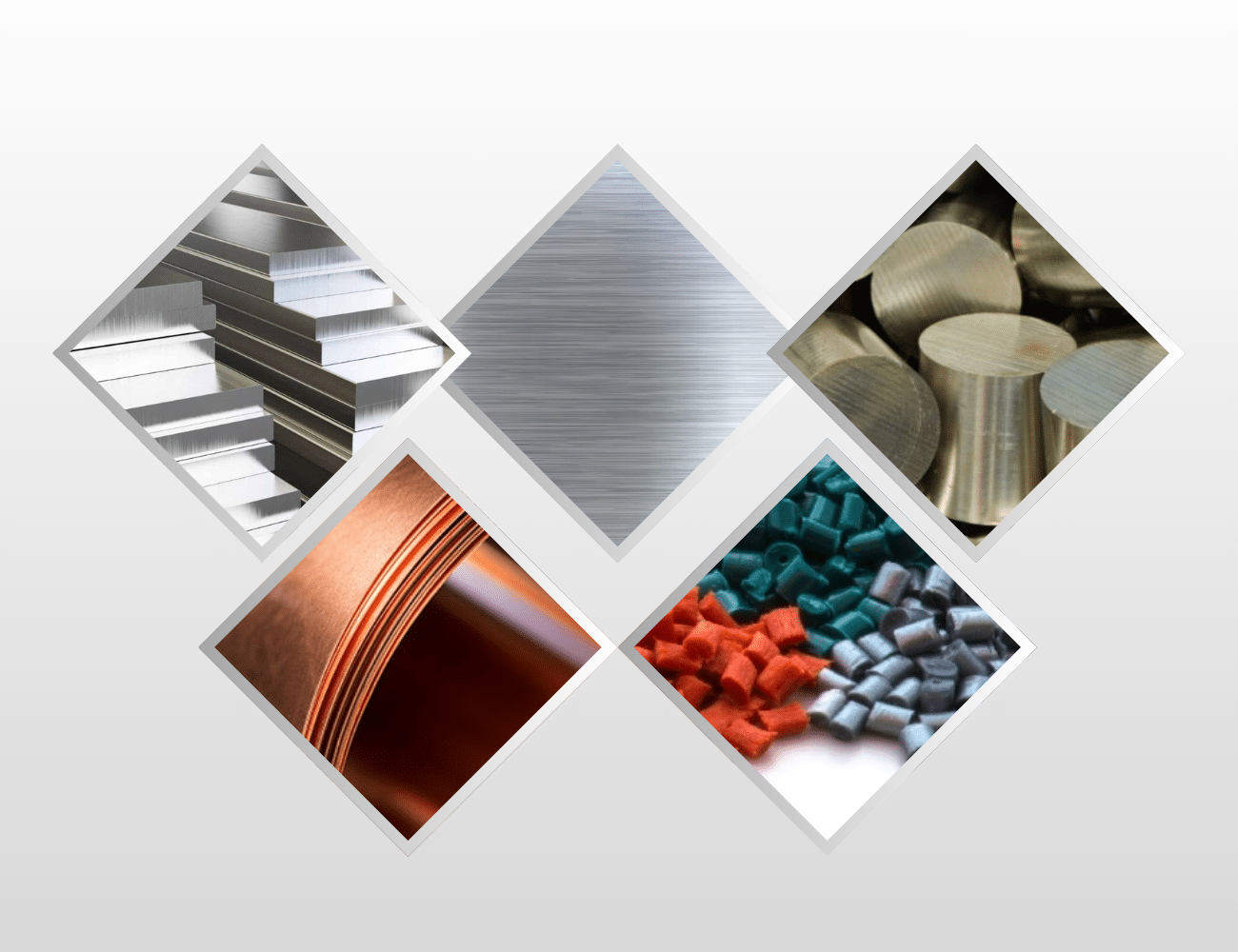

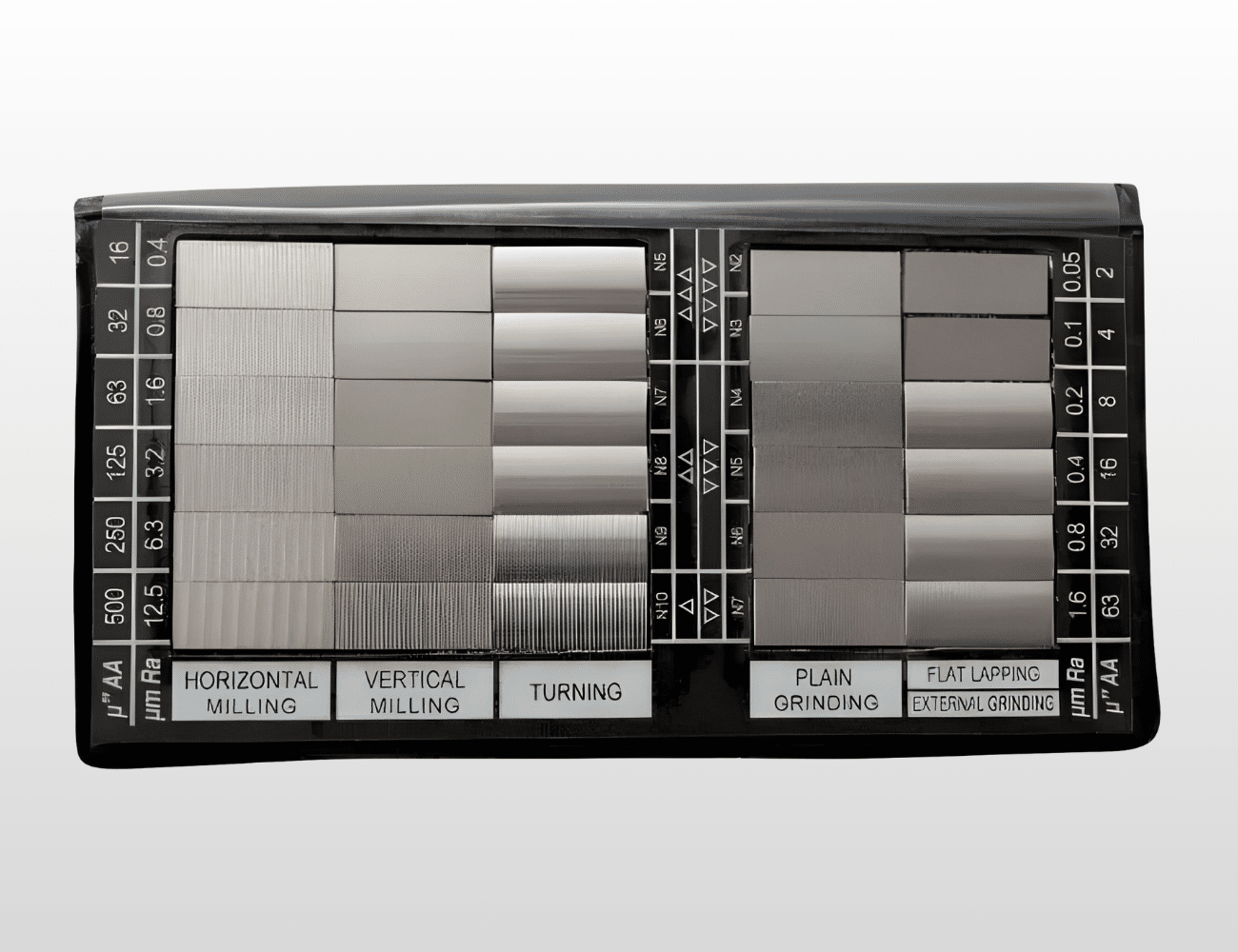

Hydrogen fuel cell plates demand exceptional precision to ensure optimal performance and durability. Tolerances of ±0.0005″ to ±0.001″ are standard for critical dimensions, particularly for flatness and parallelism across the plate surface. Surface finish requirements typically range from Ra 0.4μm to 1.6μm to minimize contact resistance and prevent gas leakage. Material specifications must balance electrical conductivity, corrosion resistance, and mechanical strength—common materials include 316L stainless steel, titanium alloys, graphite composites, and coated aluminum.

The plates must withstand operating temperatures from -40°C to 120°C and resist chemical degradation from acidic or alkaline environments. Flow-field channel depths typically range from 0.5mm to 1.5mm with precise width tolerances to ensure uniform gas distribution. Additionally, plates require excellent electrical conductivity (≤20 mΩ·cm²) and minimal contact resistance to maximize fuel cell efficiency and power output.

C. Manufacturing Challenges & Solutions

Machining hydrogen fuel cell plates presents unique challenges due to their complex flow-field geometries and demanding material properties. Thin-wall machining of delicate channel patterns requires advanced toolpath strategies to prevent vibration and maintain dimensional accuracy. Hard materials like titanium and stainless steel generate significant heat and tool wear, while graphite composites produce dust that requires specialized containment and handling. Achieving consistent flatness across large plate surfaces while maintaining micro-level channel accuracy demands precise workholding and thermal management.

Yicen Precision overcomes these challenges through advanced 5-axis CNC machining centers equipped with high-speed spindles and precision cutting tools designed for specific materials. Our CAM software optimizes toolpaths for minimal tool deflection and maximum surface quality. We employ adaptive machining strategies that adjust feed rates and cutting parameters in real-time based on material response.

Quality control is paramount—every hydrogen fuel cell plate undergoes CMM inspection to verify dimensional accuracy, flatness measurements using optical comparators, and surface roughness testing. Our in-process monitoring systems detect potential defects immediately, ensuring consistent quality across production runs. For graphite materials, we utilize dust extraction systems and specialized coatings to prevent contamination.

D. Applications & Use Cases

Hydrogen fuel cell plates manufactured by Yicen Precision serve diverse renewable energy applications:

- Automotive Fuel Cell Vehicles – Bipolar plates for hydrogen-powered cars, buses, and commercial vehicles

- Stationary Power Generation – Combined heat and power (CHP) systems for residential and industrial facilities

- Backup Power Systems – Uninterruptible power supplies (UPS) for data centers and telecommunications infrastructure

- Material Handling Equipment – Fuel cell forklifts and warehouse automation systems

- Marine Applications – Auxiliary power units for ships and submarines

- Portable Power Devices – Battery replacement systems for remote monitoring and emergency equipment

- Grid Energy Storage – Large-scale hydrogen energy storage systems for renewable energy integration

E. Why Choose Yicen Precision for Hydrogen Fuel Cell Plates?

Yicen Precision brings specialized expertise in renewable energy component manufacturing, with proven capabilities in producing high-performance hydrogen fuel cell plates. Our rapid prototyping services enable design validation within 3-5 days, accelerating your development timeline from concept to production. We offer seamless scalability from prototype quantities to high-volume production runs exceeding 10,000 units, maintaining consistent quality throughout.

Our engineering team provides comprehensive DFM (Design for Manufacturing) consultation, optimizing your fuel cell plate designs for manufacturability, cost-efficiency, and performance. We maintain complete material traceability and certification documentation, essential for renewable energy industry compliance and quality audits. Every component includes detailed inspection reports and material certifications.

By combining advanced machining technology with lean manufacturing principles, we deliver cost-effective solutions that don’t compromise on quality. Our strategic location and efficient production processes ensure competitive pricing while meeting aggressive delivery schedules. Contact us for a custom quote and discover how our hydrogen fuel cell plate manufacturing expertise can accelerate your renewable energy projects.