We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

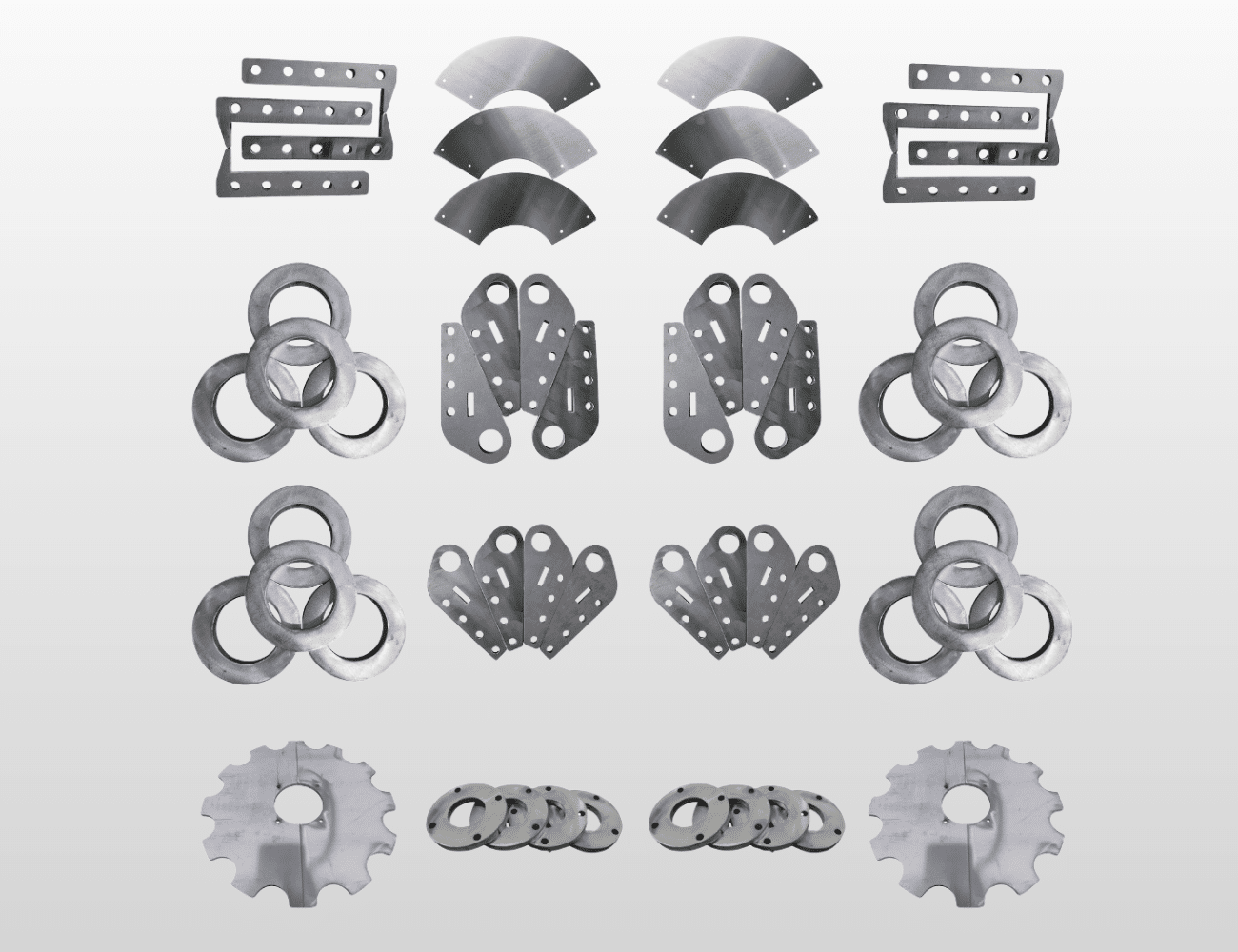

Engineered solar panel mounting brackets manufactured with precision CNC machining for secure, long-lasting photovoltaic installations. Our advanced manufacturing capabilities produce corrosion-resistant brackets that maintain structural integrity through decades of environmental exposure while ensuring optimal panel alignment for maximum energy capture. Request your custom solar mounting solution today.

The transition to clean and renewable energy requires components that can withstand extreme conditions and deliver consistent performance. Yicen Precision plays a crucial role in this mission by providing CNC-machined parts designed for wind, solar, and energy storage systems. From turbine hubs to battery casings, our machining expertise ensures strength, durability, and flawless integration, helping energy innovators push forward with confidence.

Solar panel mounting brackets provide the critical structural foundation for photovoltaic arrays, securing panels at precise angles while withstanding wind loads, snow accumulation, and seismic forces over 25-30 year operational lifespans. These components must deliver exceptional dimensional consistency for proper panel alignment and employ materials that resist corrosion in diverse environmental conditions from coastal installations to desert climates.

Yicen Precision specializes in solar panel mounting brackets CNC machining utilizing our advanced 3-axis and 4-axis milling centers optimized for high-volume production with consistent repeatability. We machine mounting brackets from aluminum alloys including 6061-T6 and 6063-T5, stainless steel grades 304 and 316, and galvanized steel, maintaining tolerances within ±0.005″ on critical mounting holes and interface surfaces. Our ISO 9001-compliant manufacturing processes incorporate automated quality inspection systems that verify every bracket meets specifications for hole positioning, flatness, and dimensional accuracy. From residential rooftop systems to utility-scale solar farms, we deliver solar mounting bracket manufacturing that ensures reliable performance and simplified installation.

We engineer high-performance CNC components tailored for renewable energy systems, from wind and solar to advanced battery technologies, built for durability and sustainability.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

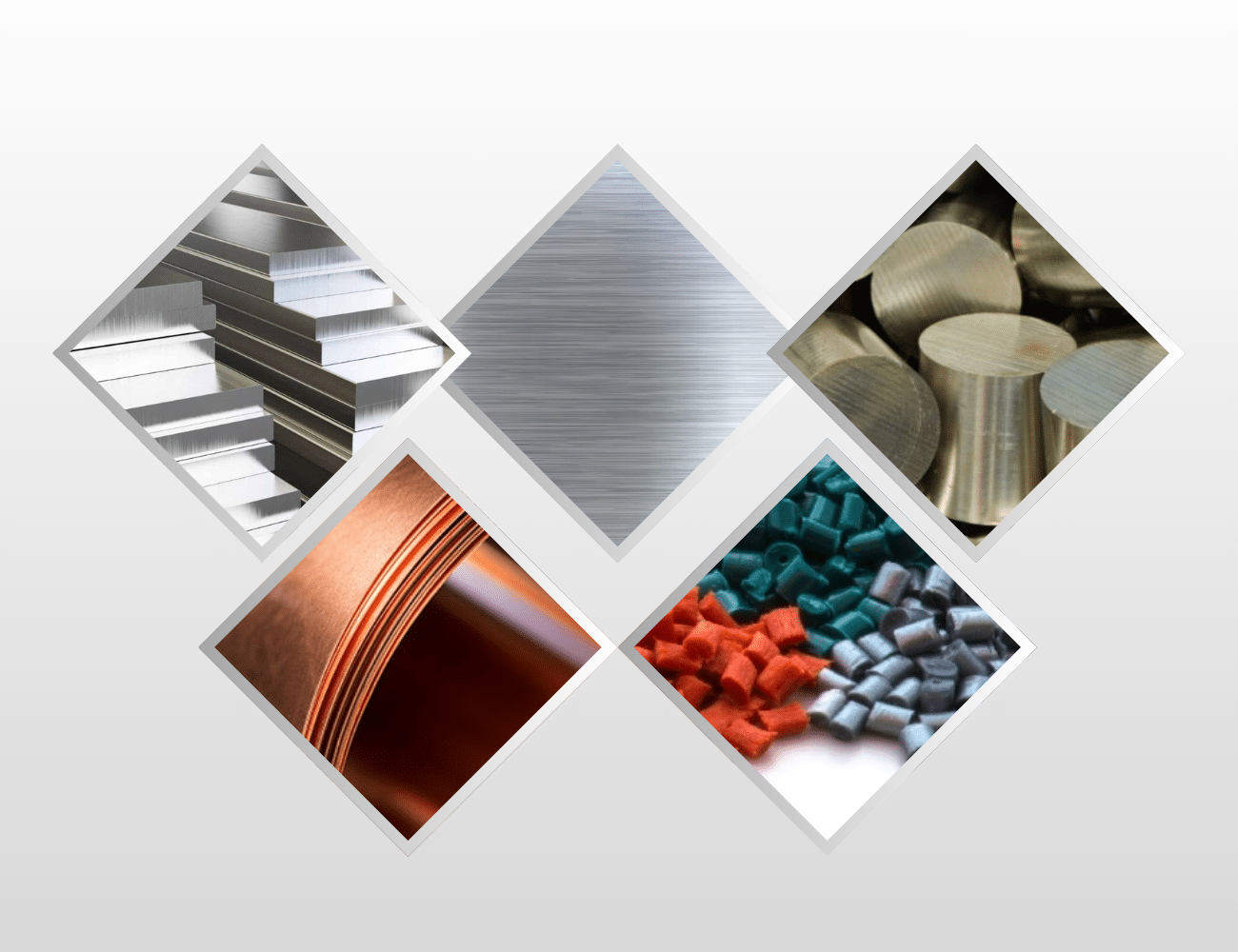

Yicen Precision offers a wide selection of durable metals and advanced composites to meet the structural, thermal, and chemical resistance demands of wind, solar, and energy storage systems.

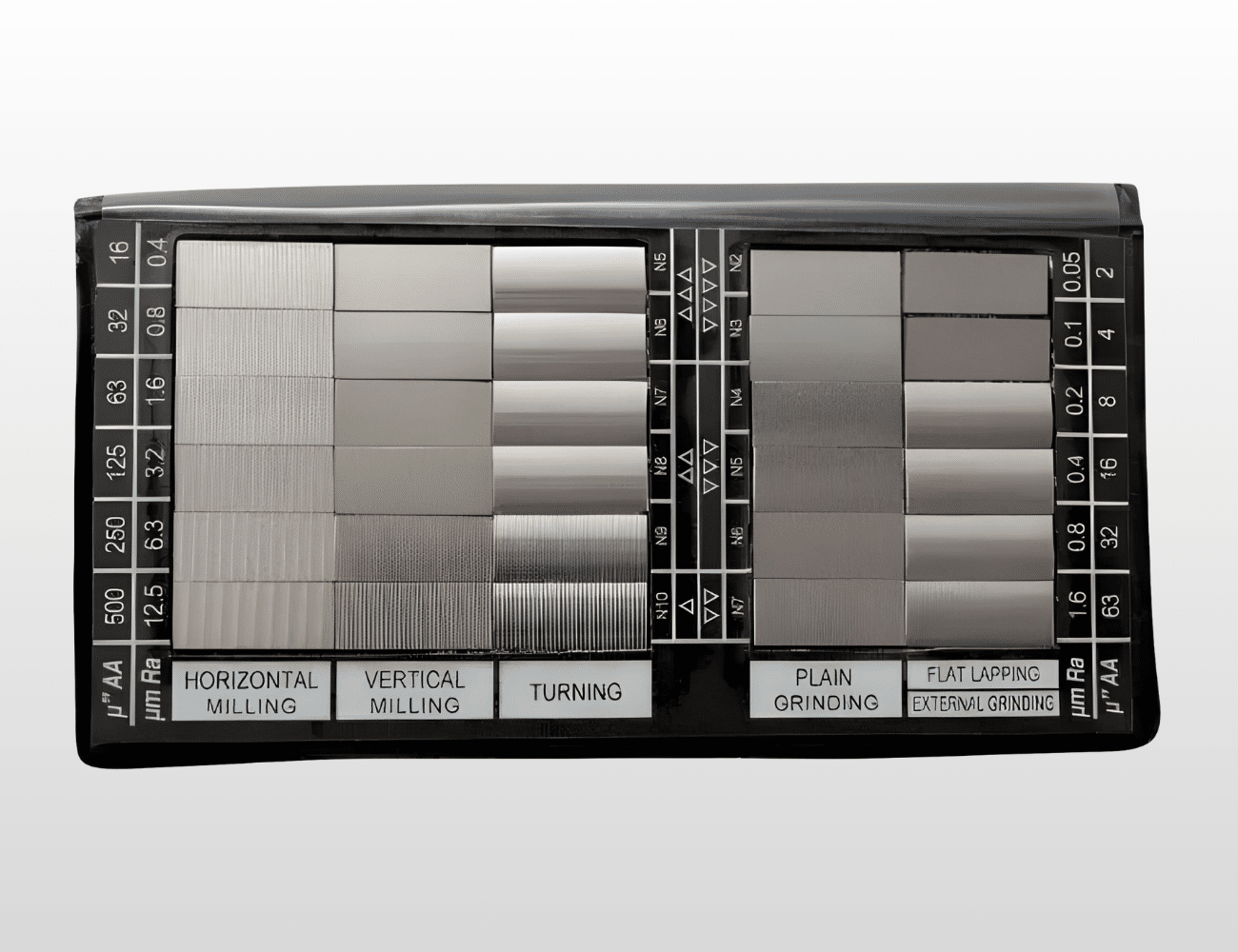

For renewable energy systems, surface finishes must ensure corrosion resistance, wear protection, and long-term reliability in harsh environments. Yicen Precision applies protective and functional coatings that extend the lifespan of components used in wind, solar, and battery applications.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

Solar panel mounting brackets are engineered hardware components that attach photovoltaic modules to roof structures, ground-mounted racking systems, or tracking assemblies, providing secure anchoring while enabling precise angular positioning for optimal solar exposure. These brackets function as the primary load-bearing interface between panels and mounting infrastructure, distributing static and dynamic loads while accommodating thermal expansion across temperature ranges from -40°F to 185°F. They are utilized across residential rooftop installations, commercial building arrays, ground-mounted solar farms, carport structures, and floating solar platforms. The bracket’s precision directly influences panel alignment uniformity, which affects both energy production efficiency and the aesthetic appearance of completed installations.

Solar panel mounting brackets CNC machining demands positional tolerances of ±0.010″ on mounting hole patterns to ensure compatibility with standardized panel frame dimensions and enable proper load distribution across attachment points. Material specifications require minimum yield strengths of 35 ksi for aluminum alloys and 30 ksi for stainless steel, with corrosion resistance verified through salt spray testing per ASTM B117 showing minimal degradation after 1,000+ hours exposure. Surface finish requirements typically specify 125 Ra on contact surfaces with additional anodizing (Type II or Type III) for aluminum components or passivation for stainless steel parts. Brackets must withstand wind loads up to 150 mph (design-dependent), snow loads exceeding 50 psf in appropriate climates, and maintain structural integrity through thermal cycling between extreme temperatures. Flatness tolerances of 0.020″ per foot ensure proper seating and load transfer, while hole diameter tolerances of ±0.003″ accommodate standard fastener assemblies.

Producing high-volume solar panel mounting brackets presents challenges in maintaining consistent hole positioning across thousands of parts, managing material costs while ensuring structural adequacy, and achieving surface treatments that provide decades of corrosion protection. The thin-wall geometries common in bracket designs are susceptible to machining distortion, while the need for multiple mounting holes demands efficient drilling strategies that prevent tool wear-induced dimensional drift. Balancing lightweight construction for installation ease against structural requirements for load-bearing capacity requires precise material removal and thickness control.

Yicen Precision addresses these challenges through dedicated production cells featuring CNC machining centers with multi-spindle drilling heads and automated tool changers, enabling simultaneous hole machining that maintains positional accuracy within ±0.005″ across entire bracket lengths. Our advanced CAM programming incorporates nesting strategies that maximize material utilization, reducing waste by 15-20% compared to conventional approaches while our climate-controlled facilities prevent thermal expansion errors during machining. Quality control measures include automated optical inspection systems that verify 100% of hole positions, CMM sampling validation for dimensional conformance, and pull-test verification of structural integrity on production samples. We partner with certified coating suppliers for post-machining treatments, ensuring AAMA 2604 compliance for anodized finishes and consistent coating thickness that extends service life.

Solar panel mounting brackets CNC machining serves diverse applications throughout the photovoltaic industry:

Our expertise in precision solar mounting bracket manufacturing combines high-volume production efficiency with the quality consistency demanded by renewable energy installations. We maintain production capacity exceeding 50,000 brackets monthly with scalability to support projects from residential installations to gigawatt-scale solar farms. Fast turnaround times of 2-3 weeks for production orders enable just-in-time delivery that aligns with construction schedules, while our prototype services support rapid design validation within 5-7 business days. Our engineering team provides comprehensive DFM consultation, optimizing bracket geometries to reduce material costs by 10-15% while maintaining structural performance and simplifying installation procedures. Complete material traceability accompanies every shipment, including mill certifications, dimensional inspection reports, and coating verification documentation. We deliver cost-effective solutions through strategic aluminum and stainless steel procurement, automated manufacturing processes that reduce per-unit costs, and quality systems that eliminate field failures—ensuring your solar installations perform reliably for decades while meeting aggressive project timelines and budget requirements.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

How does Yicen Precision help with rapid innovation in new energy?

We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

Are CNC components adaptable for hybrid energy systems?

CNC machining allows the customization of parts for hybrid setups like solar-plus-storage, ensuring compatibility across diverse energy technologies.

How does CNC machining reduce maintenance costs in renewable systems?

By producing durable, corrosion-resistant components, CNC machining minimizes wear and tear, lowering the frequency and cost of repairs in wind and solar systems.

Can CNC machining support hydrogen and fuel cell technologies?

Yes, CNC is ideal for producing precision flow plates, manifolds, and connectors in hydrogen fuel cells, where accuracy directly affects energy output and safety.