A. What are Structural Supports for Turbines?

Structural supports for turbines are load-bearing components that provide mechanical stability and mounting interfaces for wind turbine systems, solar tracking arrays, and hydroelectric installations. These components include tower flanges, nacelle mounting brackets, base plates, yaw bearing supports, hub adapters, and foundation anchor assemblies. They serve as the critical connection points between rotating components and stationary structures, transferring operational loads while maintaining precise alignment. Used in onshore and offshore wind farms, utility-scale solar installations, and distributed renewable energy systems, structural supports must deliver exceptional strength-to-weight ratios and corrosion resistance. These components directly impact turbine safety, operational efficiency, and maintenance intervals in renewable energy generation.

B. Key Technical Requirements

Precision structural supports for turbines demand robust specifications to ensure safety and longevity under extreme operating conditions. Tolerances of ±0.005″ to ±0.010″ are standard for mounting surfaces and bolt-hole patterns, with flatness specifications critical for proper load distribution. Larger components may require position tolerances within ±0.020″ across extended dimensions.

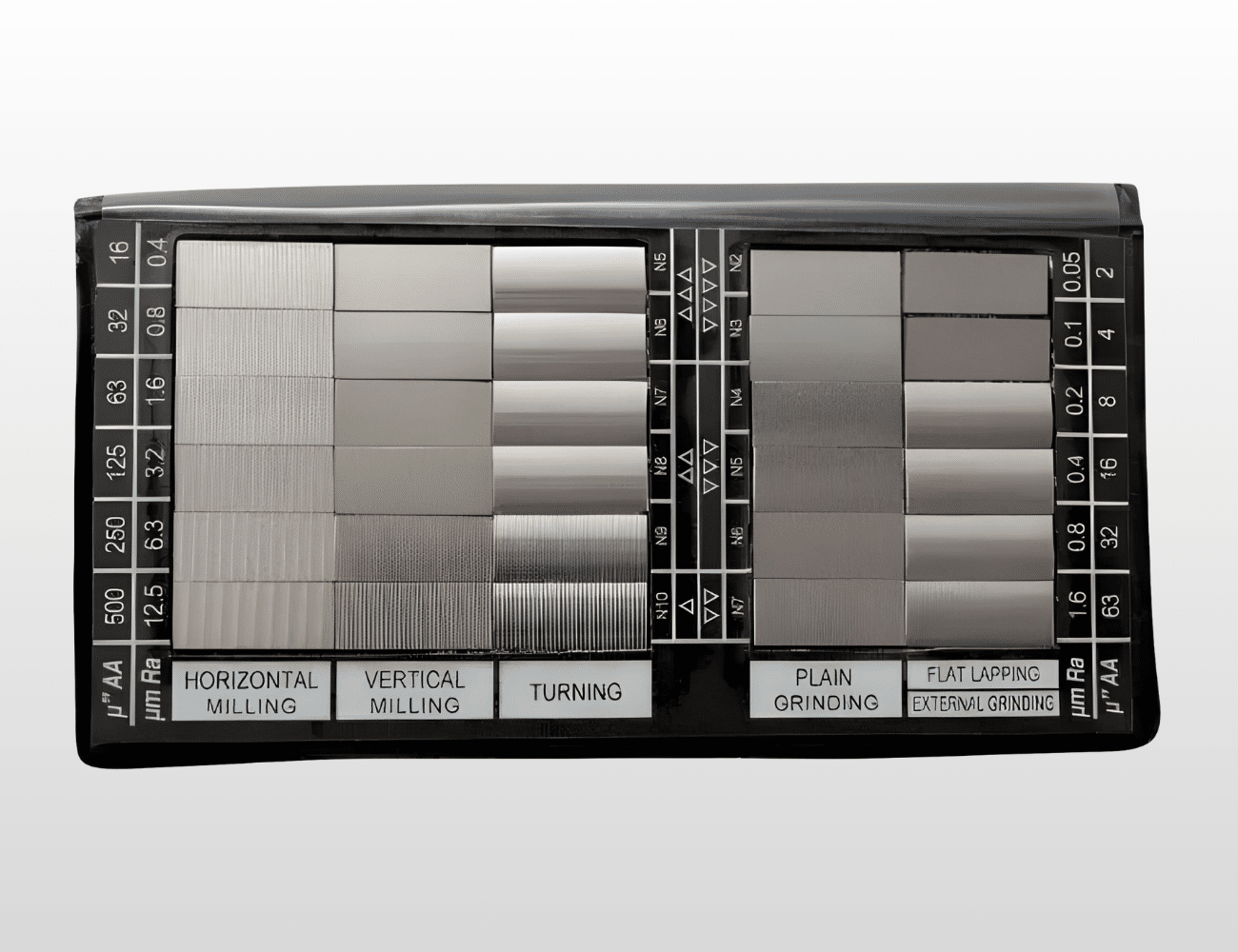

Material specifications prioritize high tensile strength, fatigue resistance, and corrosion protection. Common materials include carbon steel ASTM A36, stainless steel 304/316L, aluminum 6061-T6 and 7075-T6, and ductile iron Grade 65-45-12. Surface finish requirements typically range from Ra 3.2μm to 6.3μm for mounting interfaces, with protective coatings applied post-machining.

Structural supports must withstand static loads exceeding 50 tons and dynamic fatigue cycles over 20+ year service lives. They must perform reliably in temperature ranges from -40°C to +60°C and resist corrosion in marine environments for offshore installations. Bolt-hole patterns must maintain precise spacing (typically ±0.5mm) to ensure proper assembly alignment. Material certifications and traceability are mandatory for critical structural applications.

C. Manufacturing Challenges & Solutions

Machining structural supports for turbines presents significant challenges due to component size, material properties, and precision requirements. Large-scale workpieces weighing hundreds to thousands of kilograms require specialized workholding and crane systems for safe handling. Hard materials like high-strength steel generate substantial cutting forces and heat, accelerating tool wear. Maintaining tight tolerances across large dimensions demands thermal stability and sophisticated measurement strategies. Complex bolt-hole patterns with precise angular spacing require multi-axis positioning accuracy.

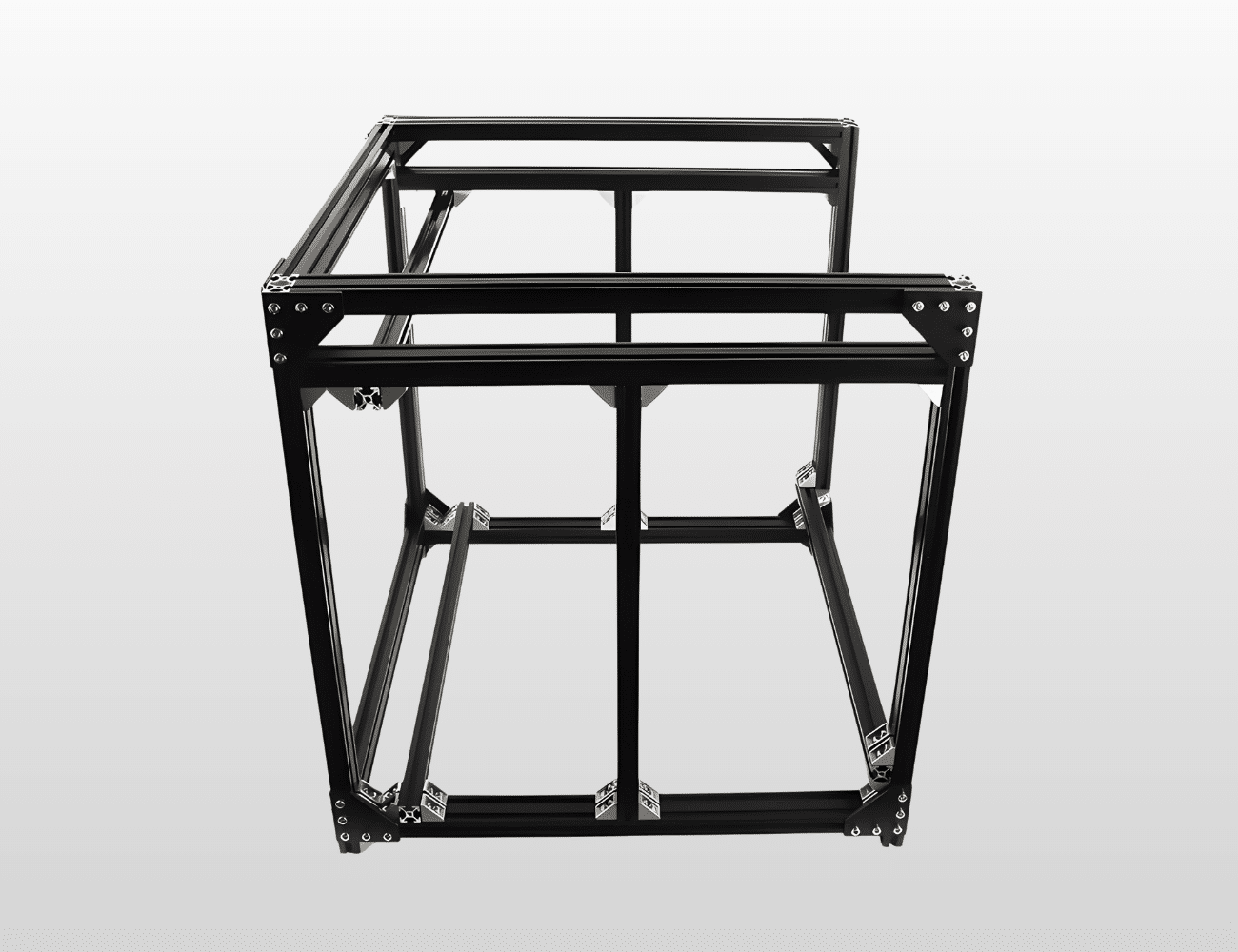

Yicen Precision addresses these challenges through heavy-duty 5-axis CNC machining centers with reinforced beds and high-torque spindles capable of handling large structural components. Our advanced CAM software optimizes toolpaths for efficient material removal while managing cutting forces and tool life. We employ stress-relief processes and controlled machining sequences to prevent warping in large workpieces.

Quality assurance utilizes portable CMM systems and laser tracking for in-situ dimensional verification of large components. Our inspection protocols include flatness measurement, bolt-hole position verification, and surface finish analysis. Material testing and certification ensure compliance with structural engineering specifications. Climate-controlled manufacturing areas minimize thermal expansion effects during precision operations. Request technical consultation to discuss your specific structural support requirements.

D. Applications & Use Cases

Structural supports for turbines manufactured by Yicen Precision serve critical renewable energy applications:

- Wind Turbine Tower Flanges – Connection interfaces for segmented tower sections in onshore and offshore installations

- Nacelle Mounting Structures – Support frames securing generator housing and drivetrain assemblies

- Yaw Bearing Supports – Ring structures enabling nacelle rotation for wind direction tracking

- Hub Adapter Plates – Connection interfaces between rotor blades and main shaft assemblies

- Solar Tracking Base Mounts – Foundation supports for single and dual-axis solar tracking systems

- Foundation Anchor Assemblies – Transition pieces connecting turbine structures to foundation systems

- Gearbox Mounting Brackets – Precision-machined supports for drivetrain component installation

E. Why Choose Yicen Precision for Structural Supports for Turbines?

Yicen Precision combines heavy-industrial machining capabilities with precision manufacturing expertise to deliver superior structural supports for renewable energy applications. Our large-format machining capacity accommodates components up to 3000mm diameter and 10,000kg weight, eliminating the need for assembly of smaller segments. We offer rapid prototyping services for design validation within 7-10 days, plus seamless scalability to production volumes.

Our engineering team provides comprehensive DFM consultation, optimizing designs for structural performance, manufacturability, and cost-efficiency. We analyze stress distribution, suggest material alternatives, and refine geometries to enhance component longevity. Complete material traceability and certification includes mill test reports, mechanical property documentation, and compliance records essential for structural engineering approvals.

By leveraging automated machining processes and strategic material sourcing, we deliver cost-effective solutions that meet stringent quality requirements without premium pricing. Our integrated supply chain ensures on-time delivery for project-critical components. Contact us for a custom quote and discover how our structural supports for turbines CNC machining expertise strengthens your renewable energy projects.