We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

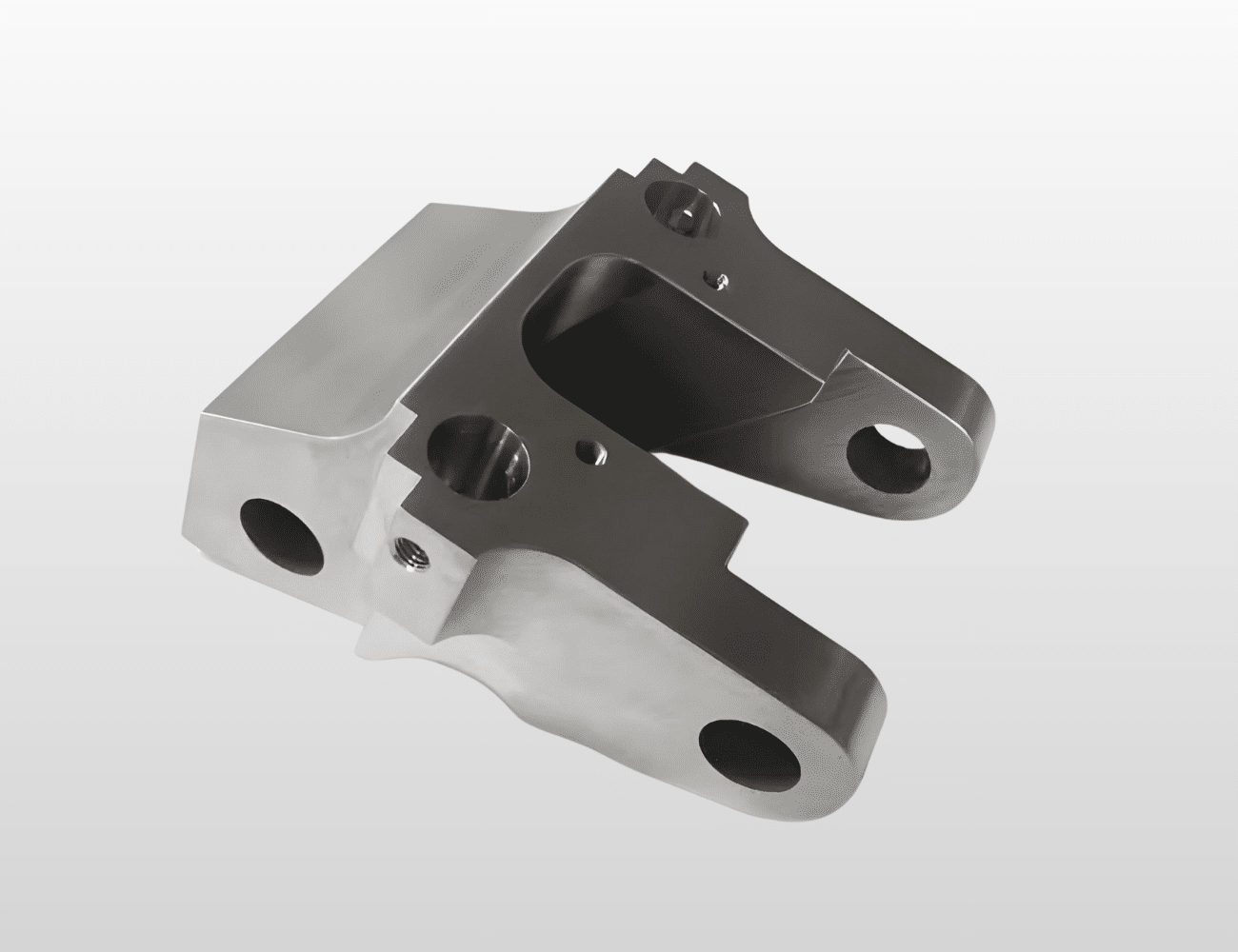

Precision-engineered wind turbine hubs and shafts manufactured to exacting tolerances for maximum energy efficiency and durability. Our advanced CNC machining capabilities deliver components that withstand extreme rotational forces and environmental conditions, ensuring reliable performance for decades. Get a custom quote for your renewable energy project today.

The transition to clean and renewable energy requires components that can withstand extreme conditions and deliver consistent performance. Yicen Precision plays a crucial role in this mission by providing CNC-machined parts designed for wind, solar, and energy storage systems. From turbine hubs to battery casings, our machining expertise ensures strength, durability, and flawless integration, helping energy innovators push forward with confidence.

Wind turbine hubs and shafts form the critical power transmission backbone of modern wind energy systems, connecting rotor blades to generators while enduring massive rotational stresses and variable loads. These components demand exceptional precision, structural integrity, and surface finish quality to maximize energy conversion efficiency and operational lifespan.

Yicen Precision delivers industry-leading wind turbine hubs CNC machining through our state-of-the-art 5-axis milling centers and heavy-duty multi-axis lathes capable of handling large-diameter workpieces. We machine wind turbine shafts and hubs from high-strength materials including forged steel alloys, ductile iron, and specialized stainless grades, maintaining tolerances within ±0.002″ across critical mating surfaces. Our ISO 9001 and AS9100-compliant manufacturing processes ensure every wind turbine hub and shaft meets stringent renewable energy industry standards for dimensional accuracy, material traceability, and non-destructive testing verification.

We engineer high-performance CNC components tailored for renewable energy systems, from wind and solar to advanced battery technologies, built for durability and sustainability.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

Yicen Precision offers a wide selection of durable metals and advanced composites to meet the structural, thermal, and chemical resistance demands of wind, solar, and energy storage systems.

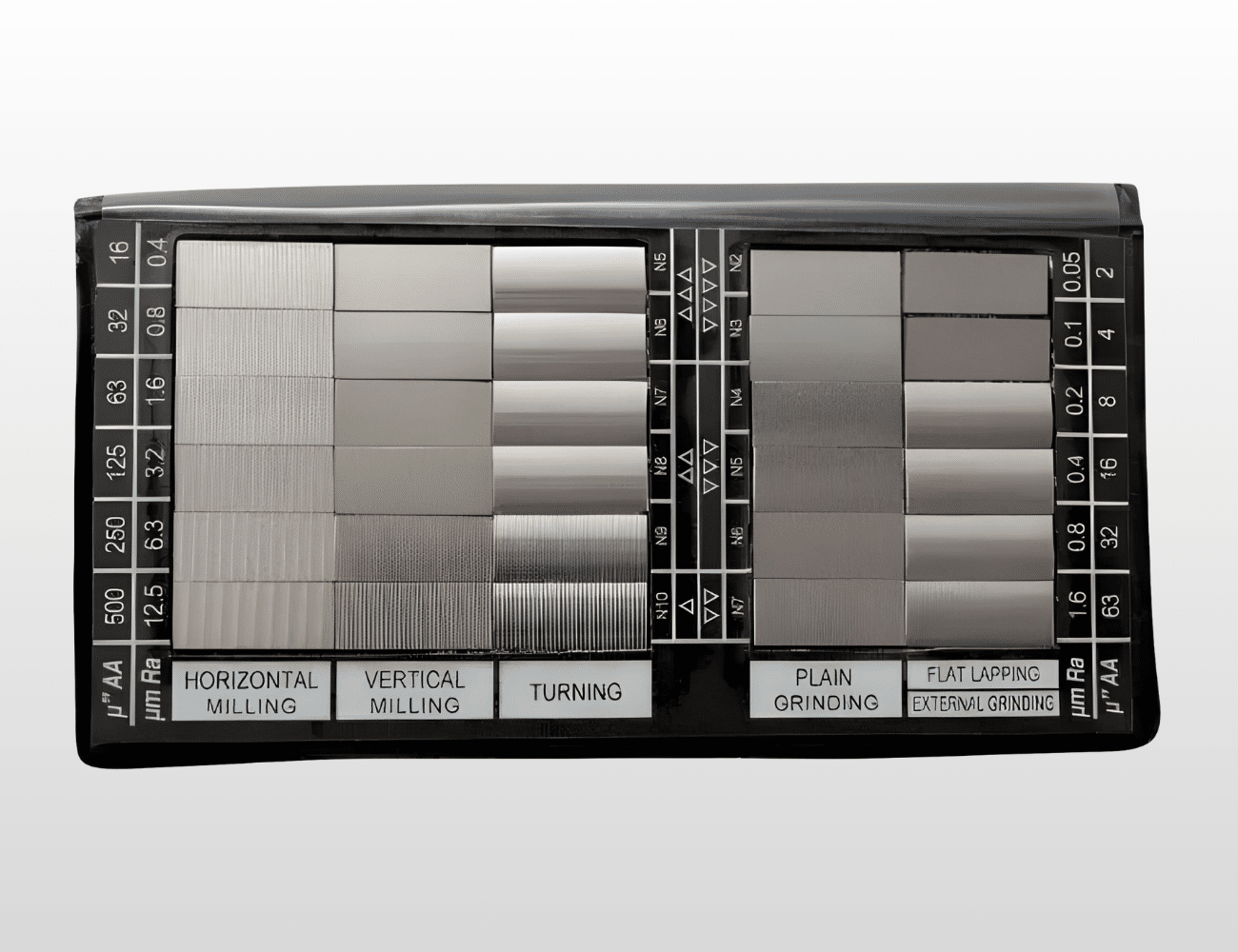

For renewable energy systems, surface finishes must ensure corrosion resistance, wear protection, and long-term reliability in harsh environments. Yicen Precision applies protective and functional coatings that extend the lifespan of components used in wind, solar, and battery applications.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

Wind turbine hubs serve as the central mounting structure that connects rotor blades to the main shaft, distributing aerodynamic loads and enabling pitch adjustment mechanisms. The main shaft transmits rotational energy from the rotor assembly to the gearbox and generator, functioning as the primary torque transfer component in the drivetrain. These components are essential in utility-scale wind farms, offshore wind installations, and distributed generation systems, where they must operate reliably under continuous cyclic loading, temperature fluctuations, and corrosive atmospheric conditions. The hub’s structural integrity directly impacts blade alignment and system balance, while shaft precision affects bearing life and energy conversion efficiency.

Wind turbine hubs CNC machining requires maintaining positional tolerances of ±0.002″ on blade mounting interfaces and concentricity within 0.001″ TIR on bearing journals to prevent vibration-induced failures. Material specifications typically call for ASTM A536 Grade 65-45-12 ductile iron for hubs or AISI 4140/4340 alloy steel for shafts, with yield strengths exceeding 65 ksi and impact toughness verified through Charpy V-notch testing. Surface finish requirements range from 63 Ra on general surfaces to 32 Ra or better on bearing seats and seal contact areas. Components must withstand bending moments exceeding 2 million ft-lbs and fatigue loading cycles in the hundreds of millions over 20-25 year service lives. Corrosion protection through specified coatings and material treatments is mandatory for offshore and coastal installations.

Machining large-diameter wind turbine hubs presents significant challenges including workpiece deflection during heavy cuts, thermal distortion from extended machining cycles, and maintaining geometric accuracy across features spanning several feet. The combination of interrupted cuts on hub blade mounts and deep-cavity pocketing for weight reduction demands robust tooling strategies and dynamic cutting parameters. Wind turbine shaft manufacturing faces difficulties in achieving straightness tolerances below 0.003″ per foot while machining lengthy components and maintaining surface finish uniformity on journal surfaces.

Yicen Precision overcomes these challenges through our heavy-duty 5-axis horizontal machining centers with rigid construction and advanced vibration dampening, enabling stable material removal on large castings and forgings. Our adaptive CAM programming optimizes tool engagement angles and feed rates based on real-time cutting force monitoring, while climate-controlled manufacturing environments prevent thermal growth variations. Precision inspection protocols include CMM verification of all critical dimensions, laser alignment measurement for shaft straightness, and surface profilometry confirming bearing-grade finishes. We employ stress-relief heat treatments between roughing and finishing operations to minimize residual stress distortion.

Wind turbine hubs and shafts CNC machining serves critical applications across the renewable energy sector:

Our specialized expertise in precision wind turbine hubs manufacturing combines large-part machining capabilities with renewable energy industry quality standards. We maintain dedicated production cells for oversized rotating components, with crane capacity exceeding 50 tons and machine travel accommodating workpieces up to 20 feet in length. Fast turnaround times from casting receipt to finished component typically span 3-6 weeks, with prototype capabilities supporting iterative design validation. Our engineering team provides comprehensive DFM consultation, optimizing hub geometries for manufacturability while maintaining structural performance requirements. Complete material traceability documentation accompanies every shipment, including mill certifications, heat treatment records, and dimensional inspection reports. We deliver cost-effective solutions through strategic material procurement partnerships and efficient machining strategies that reduce cycle times without compromising the tight tolerances and surface quality critical to wind turbine reliability.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

How does Yicen Precision help with rapid innovation in new energy?

We provide fast-turnaround prototyping and small-batch CNC runs, enabling energy innovators to test new designs and move quickly from concept to deployment.

Are CNC components adaptable for hybrid energy systems?

CNC machining allows the customization of parts for hybrid setups like solar-plus-storage, ensuring compatibility across diverse energy technologies.

How does CNC machining reduce maintenance costs in renewable systems?

By producing durable, corrosion-resistant components, CNC machining minimizes wear and tear, lowering the frequency and cost of repairs in wind and solar systems.

Can CNC machining support hydrogen and fuel cell technologies?

Yes, CNC is ideal for producing precision flow plates, manifolds, and connectors in hydrogen fuel cells, where accuracy directly affects energy output and safety.