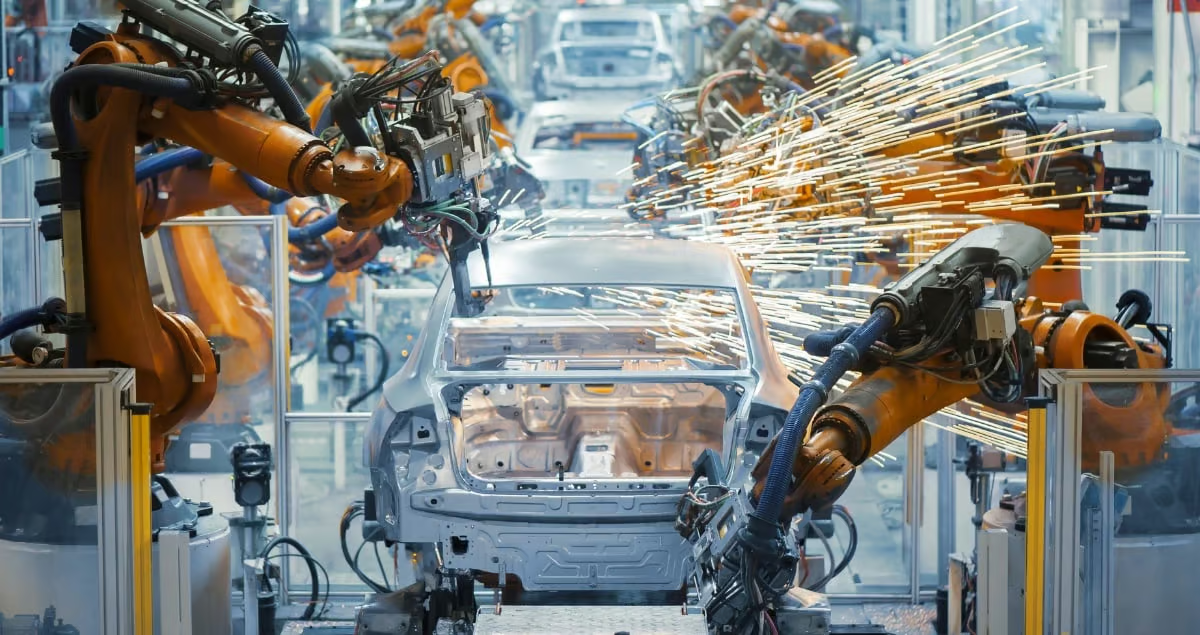

Robotics is transforming the future across industries like manufacturing, logistics, healthcare, agriculture, and defense. From robotic arms on assembly lines to autonomous delivery bots and surgical assistants, these systems rely on high-performance mechanical components to function with precision, speed, and reliability.

At Yicen Precision, we help robotics innovators bring their systems to life. With advanced CNC machining capabilities and a deep understanding of motion control, structural integrity, and miniaturized assemblies, we provide the critical components that drive robotic performance.

Why Precision Machining Is Critical for Robotics

Robotic systems require flawless motion and repeatability. Any deviation in alignment or mechanical performance can impact positioning accuracy, system stability, or task execution. CNC machining offers the level of precision, consistency, and material versatility necessary for the robotics industry.

Yicen Precision supports robotic developers and OEMs with:

- Tight-tolerance motion components

- Lightweight structural assemblies

- Custom enclosures and sensor housings

- High-wear interfaces and end-effectors

- Rapid prototyping and scalable production

CNC-Machined Parts We Deliver for Robotic Systems

1. Rotational and Linear Motion Components

The core of any robotic arm, actuator, or mobile system is accurate motion control. We machine:

- Shafts, gears, bushings, and pulleys

- Lead screws and guide rails

- Bearing housings and rotary joints

- Motor mounts and couplers

Our precision machining ensures smooth motion, reduced vibration, and long service life in high-cycle applications.

2. Lightweight Structural Frames and Arms

Robots must balance strength and weight. We produce:

- Arm linkages and extension tubes

- Mounting plates and base structures

- Modular chassis and panel frames

- Compact aluminum skeletons

We work with aluminum, titanium, magnesium, and carbon-fiber compatible parts for maximum strength-to-weight ratio.

3. Sensor, Camera, and Actuator Housings

Robotic perception and control require protected electronics. We manufacture:

- Enclosures for sensors and LiDAR units

- Sealed camera mounts and brackets

- Precision actuator covers

- Compact casings for embedded controls

We maintain tight tolerances for proper alignment of lenses, sensors, and electrical connectors.

4. End-Effector and Gripper Components

Robots must interact with the world and every gripper, tool, or probe requires precision. We machine:

- Custom gripper fingers

- Tool changer interfaces

- Vacuum and pneumatic fittings

- Tactile sensor mounts

We support high-precision gripping and tool-handling with rigid, repeatable designs.

From Prototypes to Production

Whether you’re a robotics startup building your first prototype or an established OEM scaling up a product line, Yicen Precision supports every stage of your development cycle.

Rapid Prototyping

We deliver fully machined parts within days—ideal for testing fit, motion, and performance.

Design for Manufacturability (DFM)

Our engineers work with your CAD models to optimize parts for precision, reliability, and simplified assembly.

Low-Volume Production

Need a batch of 10 or 100 for field testing or a pilot program? We offer flexible quantities and consistent quality.

Scalable CNC Production

Once your robot is market-ready, we support full-scale CNC manufacturing with traceability, documentation, and reliable lead times.

Applications We Serve in Robotics

Yicen Precision works with robotics companies across a broad range of sectors:

- Industrial and Factory Automation

- Autonomous Vehicles and Drones

- Medical and Surgical Robotics

- Agricultural and Environmental Robotics

- Warehouse and Logistics Systems

- Defense and Aerospace Robotics

From single-joint mechanisms to fully integrated electromechanical systems we’ve machined parts for all types of robots.

Why Do Robotics Companies Trust Yicen Precision?

- Ultra-precise CNC tolerances for motion and alignment

- Lightweight materials for mobile and aerial systems

- Fast lead times for iterative prototyping

- Flexible order volumes for R&D and market testing

- Strong communication and collaborative design reviews

- Reliable quality, packaging, and part traceability

When every micron matters, we deliver parts that meet your spec every time.