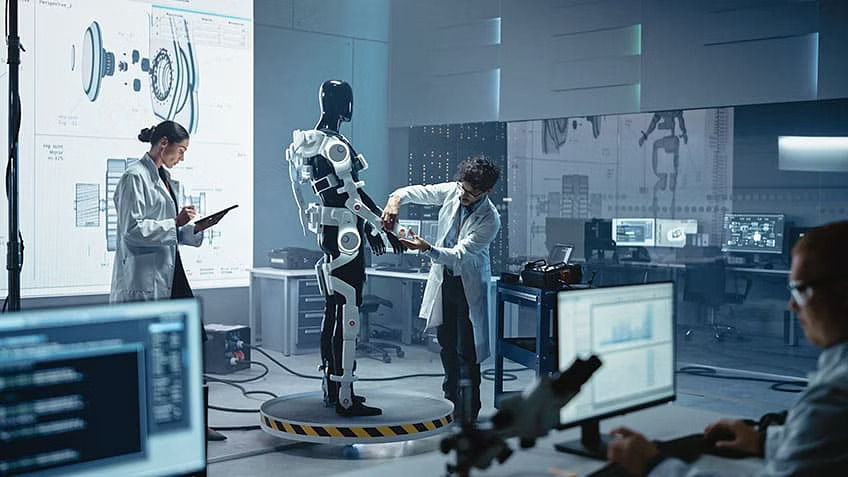

A. What are Robotic Arm Joints and End Effectors?

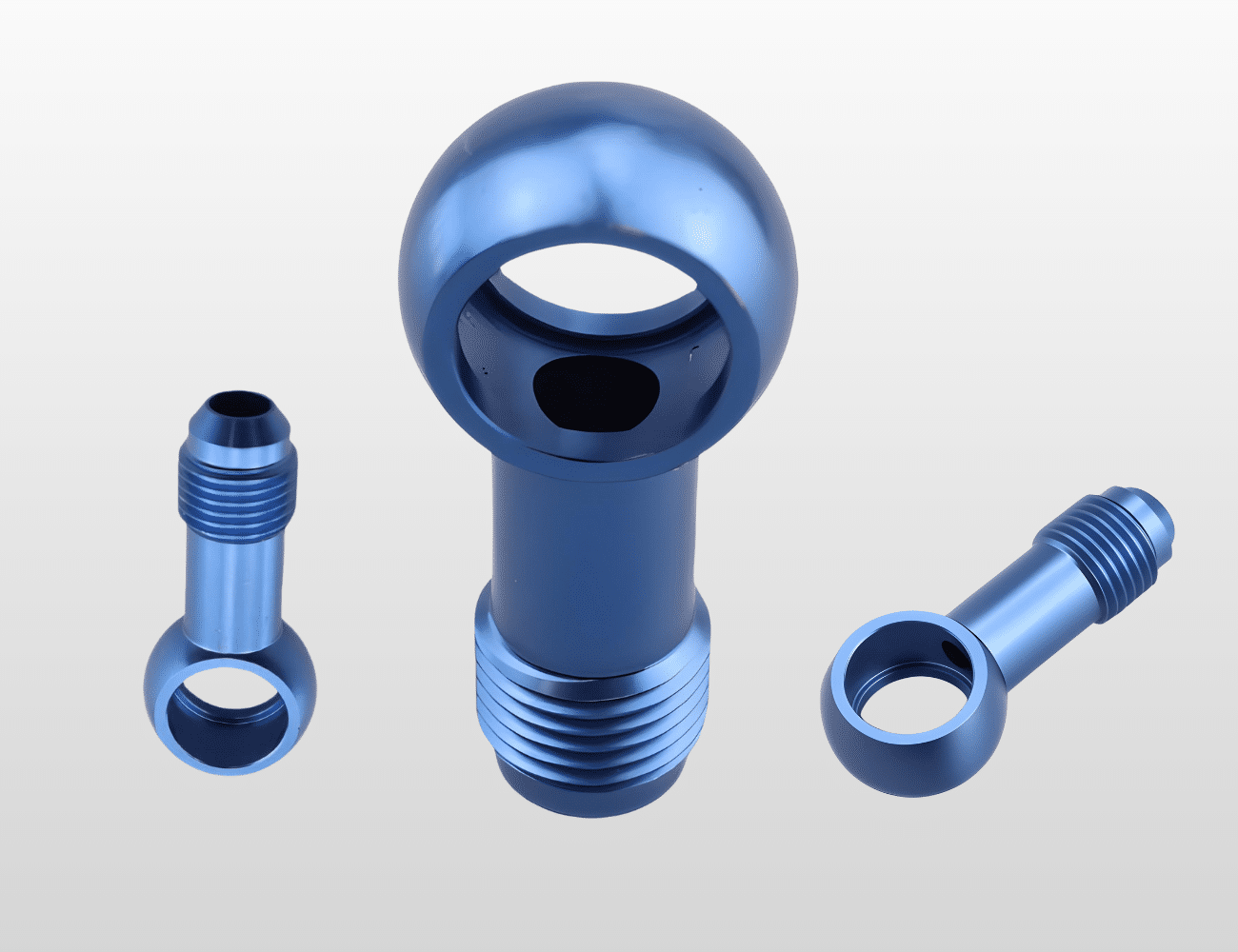

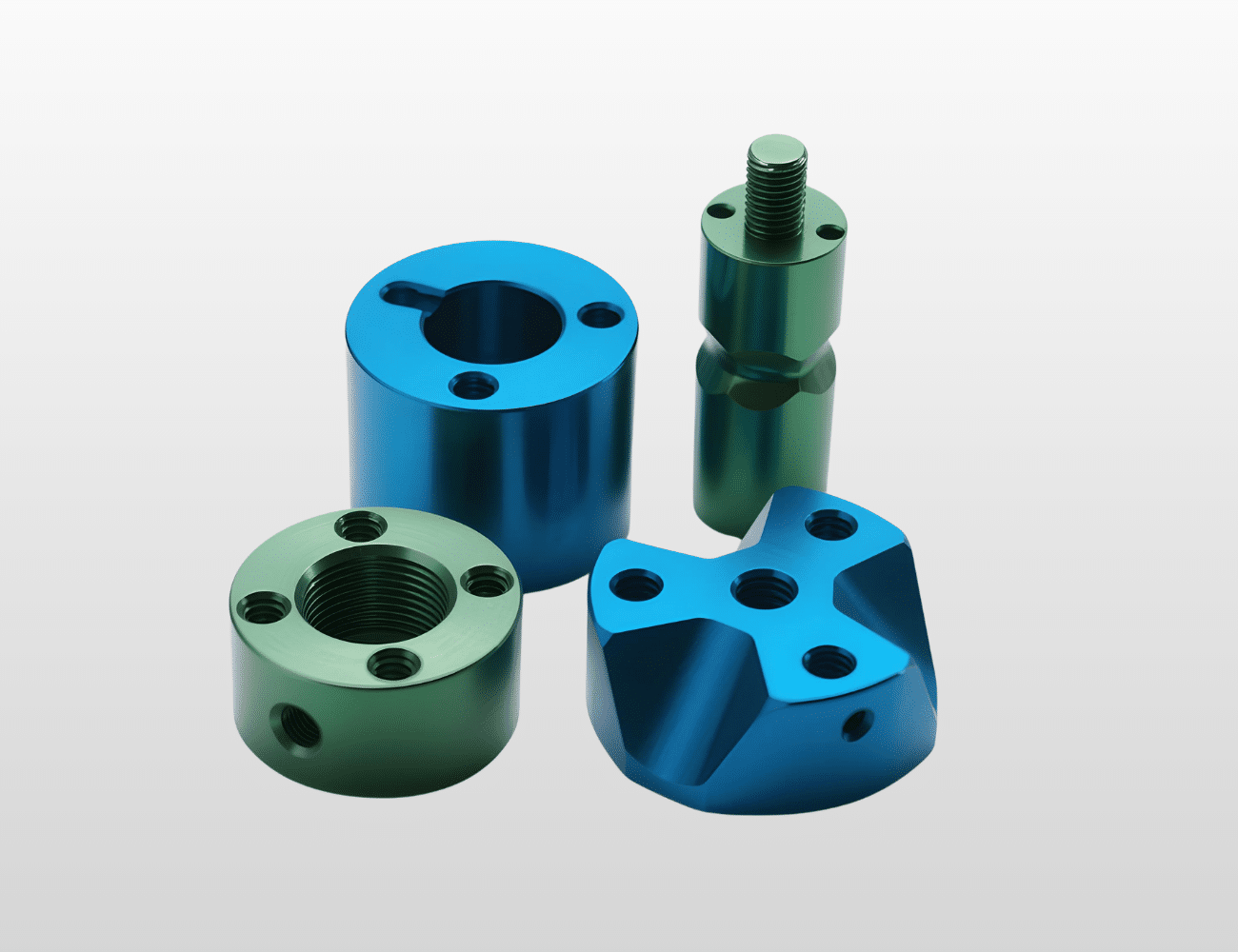

Robotic arm joints are the mechanical connection points that enable articulation and movement in robotic systems, while end effectors are the terminal devices attached to the robot arm that interact with the work environment. Joints include rotary actuators, pivot points, and articulating mechanisms that provide degrees of freedom for the robotic arm. End effectors encompass grippers, welding torches, vacuum cups, cutting tools, and specialized tooling designed for specific tasks. These components are essential in industrial automation, collaborative robots (cobots), surgical robotics, warehouse logistics systems, and precision assembly operations. The performance and longevity of any robotic system depend directly on the precision and durability of these critical machined components.

B. Key Technical Requirements

Robotic arm joints and end effectors demand exceptional precision with tolerances of ±0.0005″ to ±0.001″ to ensure smooth articulation and accurate positioning. Material specifications must account for strength-to-weight ratios, with aluminum alloys preferred for lightweight applications and titanium or stainless steel for high-load scenarios. Surface finish requirements typically range from Ra 32 to Ra 16 microinches to minimize friction and wear in moving interfaces. Components must withstand repetitive stress cycles, often exceeding millions of operations, requiring fatigue-resistant materials and proper heat treatment. Bearing surfaces demand hardness specifications between HRC 58-62 for wear resistance. Temperature considerations vary from cryogenic medical applications to high-heat welding operations, necessitating material stability across extreme ranges. Corrosion resistance is critical for cleanroom, food processing, and outdoor applications.

C. Manufacturing Challenges & Solutions

Machining robotic arm joints and end effectors presents unique challenges including complex internal passages for wiring and pneumatics, thin-walled sections susceptible to deflection, and intricate mounting features requiring multi-axis access. Material hardness in stainless steel and titanium components increases tool wear and demands specialized cutting strategies. Maintaining concentricity and perpendicularity across multiple datum features is essential for proper assembly and function.

Yicen Precision overcomes these manufacturing challenges through advanced 5-axis CNC machining that enables complete part processing in single setups, eliminating tolerance stack-up from multiple operations. Our CAM software optimizes tool paths for material removal while minimizing vibration and heat generation. Precision inspection tools including CMM (Coordinate Measuring Machines) verify all critical dimensions with documented traceability. We employ specialized fixturing systems that support delicate geometries without distortion. Our quality control measures include dimensional verification at multiple production stages, first-article inspection protocols, and statistical process control to ensure every robotic arm joint and end effector meets exact specifications for seamless integration into your robotic systems.

D. Applications & Use Cases

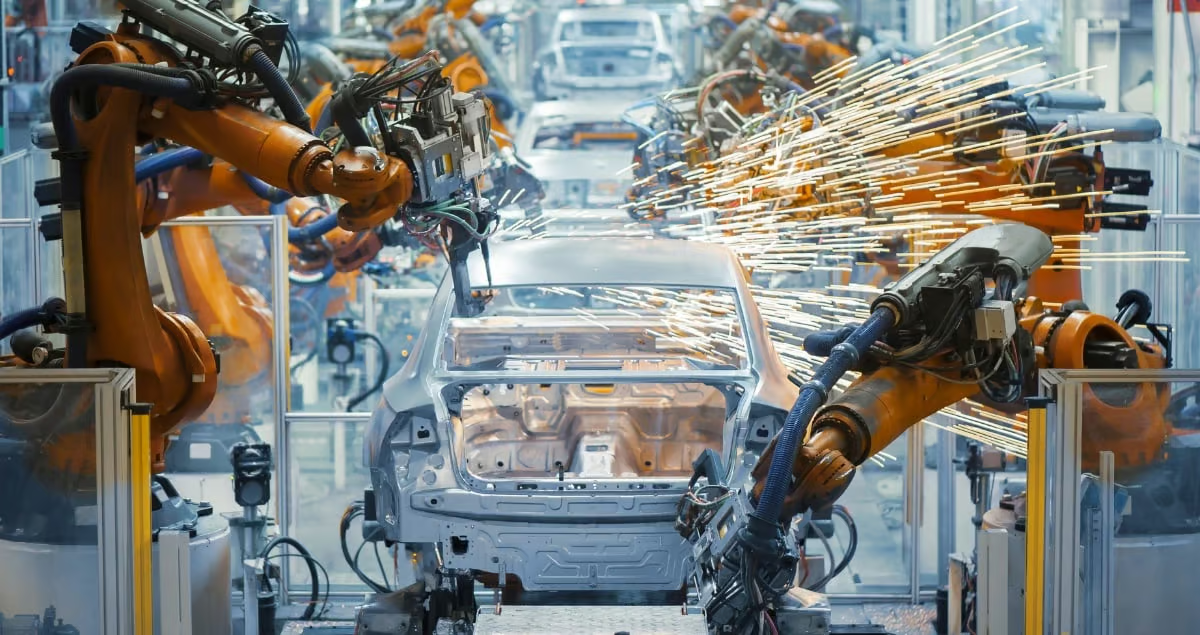

Robotic arm joints and end effectors are utilized across diverse industries:

- Industrial Automation: Assembly line robots, material handling systems, and pick-and-place operations

- Collaborative Robots (Cobots): Human-robot interaction systems in manufacturing and logistics environments

- Medical Robotics: Surgical robots, rehabilitation devices, and diagnostic equipment requiring sterile components

- Welding Systems: Robotic welding arms with torch end effectors for automotive and aerospace fabrication

- Packaging & Palletizing: High-speed gripper systems for food, pharmaceutical, and e-commerce applications

- Electronics Manufacturing: Precision placement robots for semiconductor and PCB assembly

- Agricultural Robotics: Autonomous harvesting systems and precision farming equipment

- Warehouse Logistics: Automated storage and retrieval systems with specialized gripper end effectors

E. Why Choose Yicen Precision for Robotic Arm Joints and End Effectors?

Yicen Precision delivers unmatched expertise in manufacturing robotic arm joints and end effectors with rapid turnaround times from prototype to full production runs. Our engineering team provides Design for Manufacturability (DFM) consultation to optimize your component designs for performance, cost-effectiveness, and manufacturability. We maintain complete material traceability with certified mill test reports and documentation for every batch. Our scalable production capabilities accommodate both low-volume custom projects and high-volume production orders without compromising quality standards. With state-of-the-art inspection equipment and AS9100 certification, we guarantee dimensional accuracy and surface finish consistency. Our cost-effective solutions leverage optimized machining strategies and material utilization, delivering superior robotic components that enhance your system’s reliability and operational lifespan. Contact us for a custom quote and technical consultation.