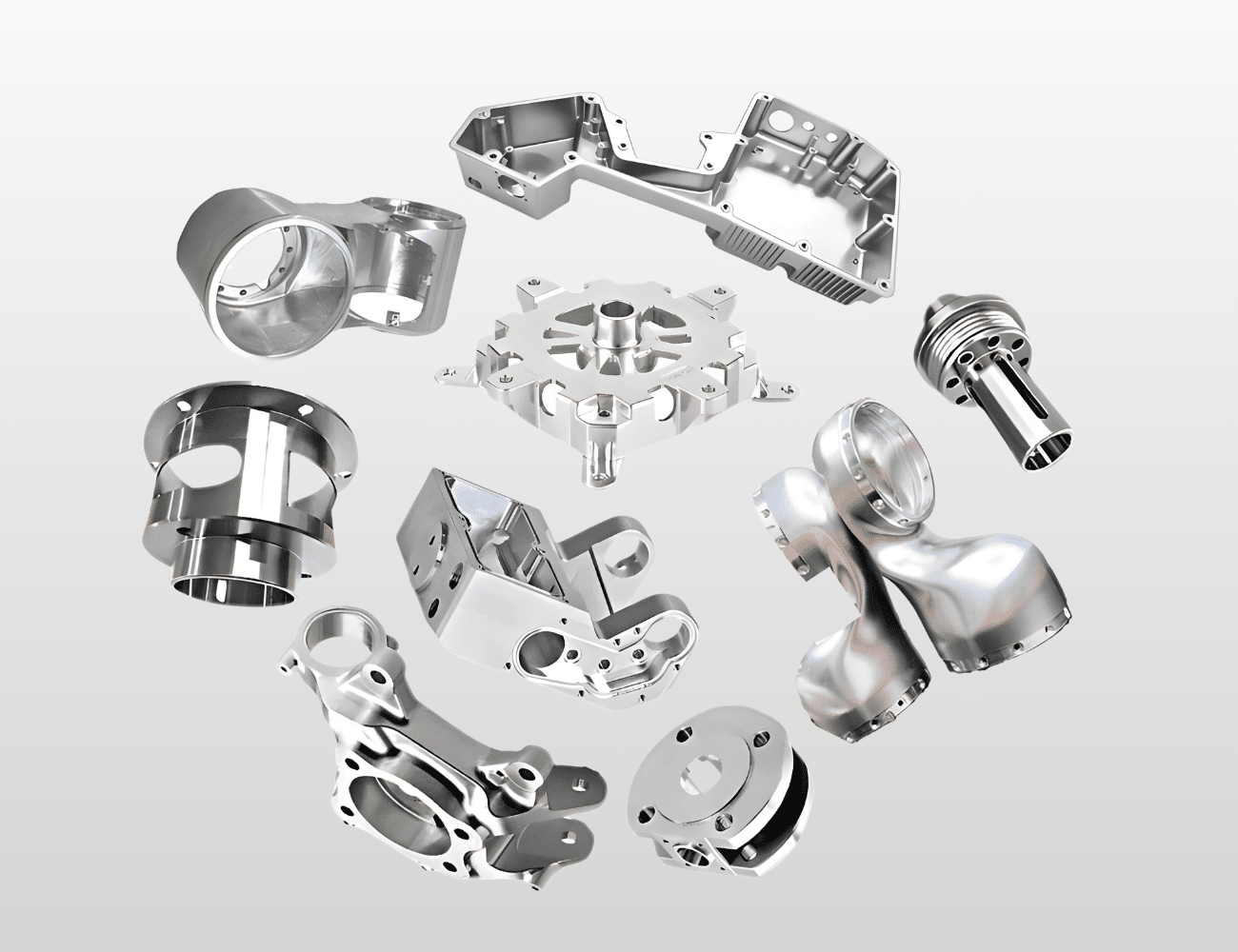

A. What is Prototyping CNC Machining?

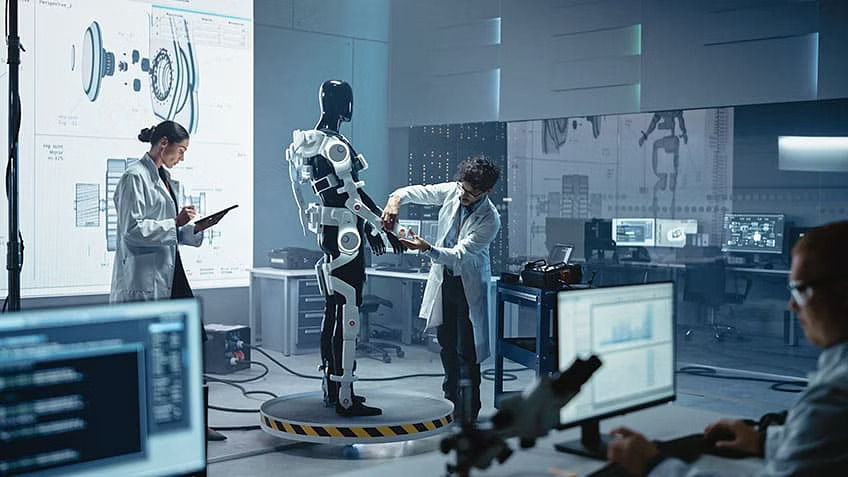

Prototyping CNC machining is the rapid fabrication of functional mechanical components from digital CAD models to validate robotic designs, test assembly fitment, evaluate material performance, and verify manufacturing feasibility before full-scale production. This process includes single-piece prototypes, small-batch pre-production runs, design iteration series, and proof-of-concept models for robotic arms, drive systems, sensor mounts, structural frames, and specialty components. Prototyping encompasses everything from initial concept models with relaxed tolerances to high-fidelity engineering prototypes matching final production specifications. These machined prototypes are essential in new robot development programs, design optimization projects, research and development initiatives, venture-backed robotics startups, and established manufacturers launching new product lines. The speed and accuracy of prototyping CNC machining directly impact development timelines, design quality, risk mitigation, investor demonstrations, and successful market entry across industrial automation, medical robotics, aerospace, and emerging robotics sectors.

B. Key Technical Requirements

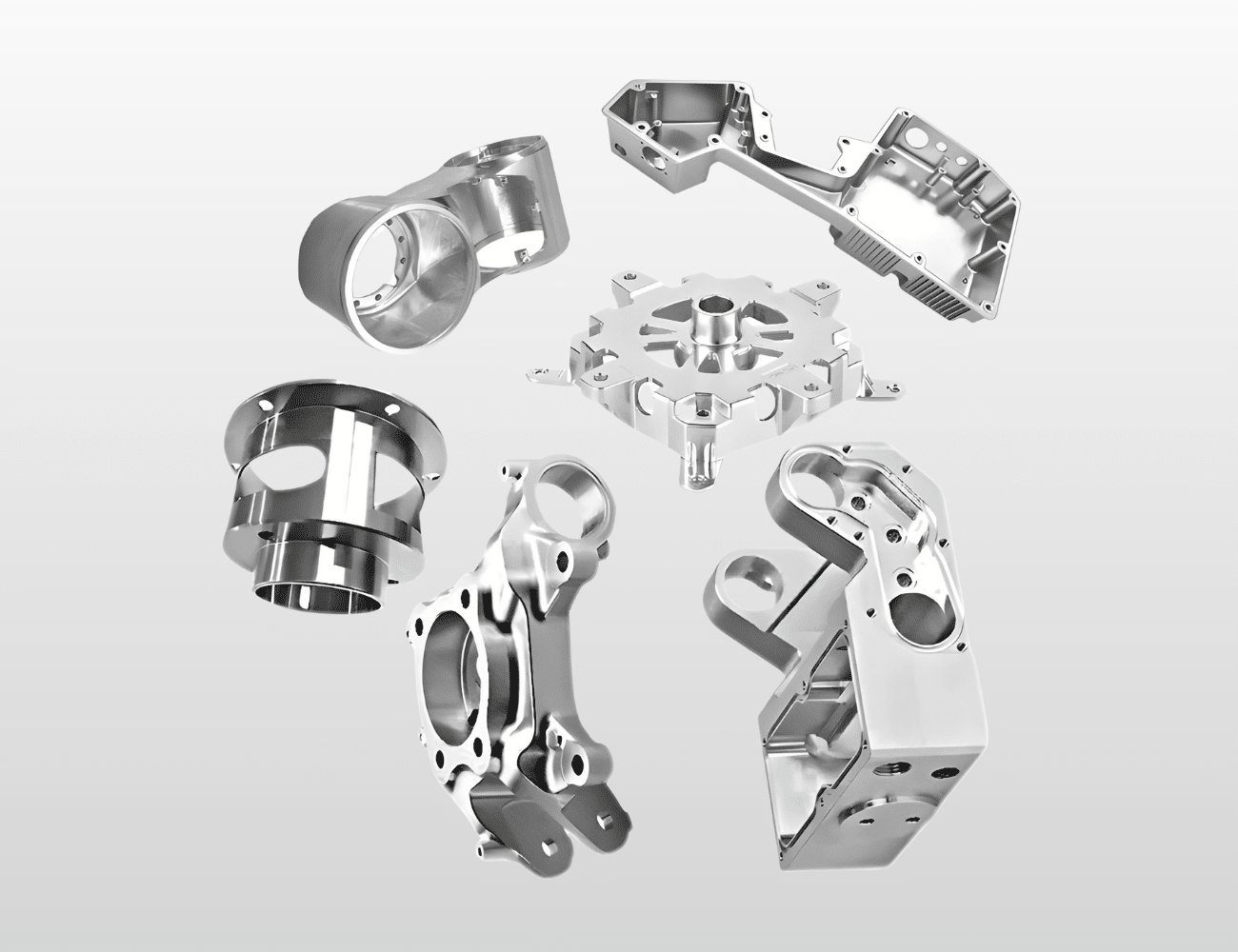

Prototyping CNC machining for robotics demands flexibility to accommodate evolving designs while maintaining tolerances of ±0.001″ to ±0.005″ depending on prototype fidelity requirements and design maturity. Early-stage concept prototypes may utilize relaxed tolerances for rapid fabrication, while engineering prototypes require production-equivalent specifications. Material specifications must match intended production materials to accurately represent thermal properties, mechanical strength, weight characteristics, and machinability. Surface finish requirements typically range from Ra 63 microinches for functional testing to Ra 32 microinches or better for customer demonstrations and final validation. Dimensional accuracy must support assembly testing, with hole positions maintaining ±0.003″ to ±0.005″ for mating component verification. Prototypes often require multiple iterations with design modifications between versions, necessitating flexible manufacturing approaches and rapid CAM programming capabilities. Documentation requirements include dimensional inspection reports, material certifications, and photography for design review meetings. Lead time expectations typically demand delivery within 1-3 weeks for most prototype components, with expedited options for critical path items. Complex assemblies may require coordination of multiple prototype parts with matching revision levels and assembly instructions.

C. Manufacturing Challenges & Solutions

Prototyping CNC machining presents unique challenges including rapid turnaround expectations that compress normal programming and setup time, frequent design changes requiring flexible manufacturing strategies, and single-piece production that eliminates efficiency gains from batch processing. Complex geometries in innovative robotic designs may push machining capabilities and require creative fixturing solutions. Material availability for specialized alloys or engineering plastics can impact lead times. Design files may contain manufacturability issues not apparent until machining begins, requiring engineer-to-engineer communication for resolution. Cost sensitivity in development budgets must be balanced against quality and speed requirements.

Yicen Precision addresses these prototyping challenges through dedicated rapid prototyping workflows that prioritize speed without compromising quality. Our experienced CAM programmers quickly analyze design files, identify potential manufacturing issues, and provide Design for Manufacturability (DFM) feedback within 24 hours of quote request. Advanced 5-axis CNC machining capabilities enable complex prototype fabrication with minimal setups, reducing programming time and improving accuracy. We maintain extensive material inventory including common aluminum alloys, stainless steels, titanium, and engineering plastics for immediate availability. Flexible scheduling accommodates urgent prototype requests with expedited processing options. Our engineering team collaborates directly with customers to resolve design questions, suggest material alternatives, or recommend geometric modifications that improve manufacturability while maintaining design intent. CMM inspection provides comprehensive dimensional reports that support design validation and inform subsequent iterations. Prototype-to-production transition support includes manufacturing process documentation, cost reduction recommendations, and scalable production planning, ensuring every prototype component delivers maximum value for design validation and successful product launch.

D. Applications & Use Cases

Prototyping CNC machining supports diverse robotic development activities:

- New Robot Development: Functional prototypes for novel robotic arm designs, gripper concepts, and motion system validation

- Design Iteration Series: Multiple component versions testing geometric variations, material alternatives, and performance optimization

- Assembly Validation: Prototype parts verifying fitment, clearances, and kinematic relationships in complex robotic assemblies

- Investor Demonstrations: High-quality prototype components for funding presentations, trade show displays, and customer evaluations

- Research Projects: University and laboratory prototypes exploring advanced robotics concepts and novel mechanisms

- Material Testing: Prototype components in various materials evaluating strength, weight, thermal properties, and machinability

- Pre-Production Pilots: Small-batch prototype runs validating manufacturing processes before full-scale production tooling investment

- Custom One-Off Systems: Specialized robotic components for unique applications, research platforms, and proof-of-concept systems

E. Why Choose Yicen Precision for Prototyping CNC Machining?

Yicen Precision delivers specialized expertise in rapid prototyping CNC machining with industry-leading turnaround times as fast as 5-7 business days for urgent projects and standard 2-3 week delivery for most prototype components. Our engineering team provides complimentary Design for Manufacturability (DFM) consultation within 24 hours, identifying potential issues, suggesting improvements, and optimizing designs for both prototyping and future production. We maintain extensive material inventory ensuring immediate availability of common robotics materials without procurement delays. Our flexible quoting accommodates single prototypes through small production batches with transparent pricing and no hidden setup fees. State-of-the-art 5-axis CNC machining capabilities handle complex geometries that challenge conventional 3-axis equipment, producing prototypes that accurately represent design intent. Comprehensive inspection services include dimensional reports, material certifications, and photographic documentation supporting design reviews and validation testing. Iterative design support tracks multiple component versions with revision control and stored CAM programs enabling rapid turnaround for design modifications. Prototype-to-production transition assistance includes manufacturing process documentation, cost optimization recommendations, and scalable production planning that accelerates market entry. Our AS9100 certification ensures quality standards match production requirements, providing confidence that prototype validation translates to production success. Contact us for a rapid quote and DFM analysis to discover how our prototyping CNC machining services can accelerate your robotic development timeline and reduce technical risk.