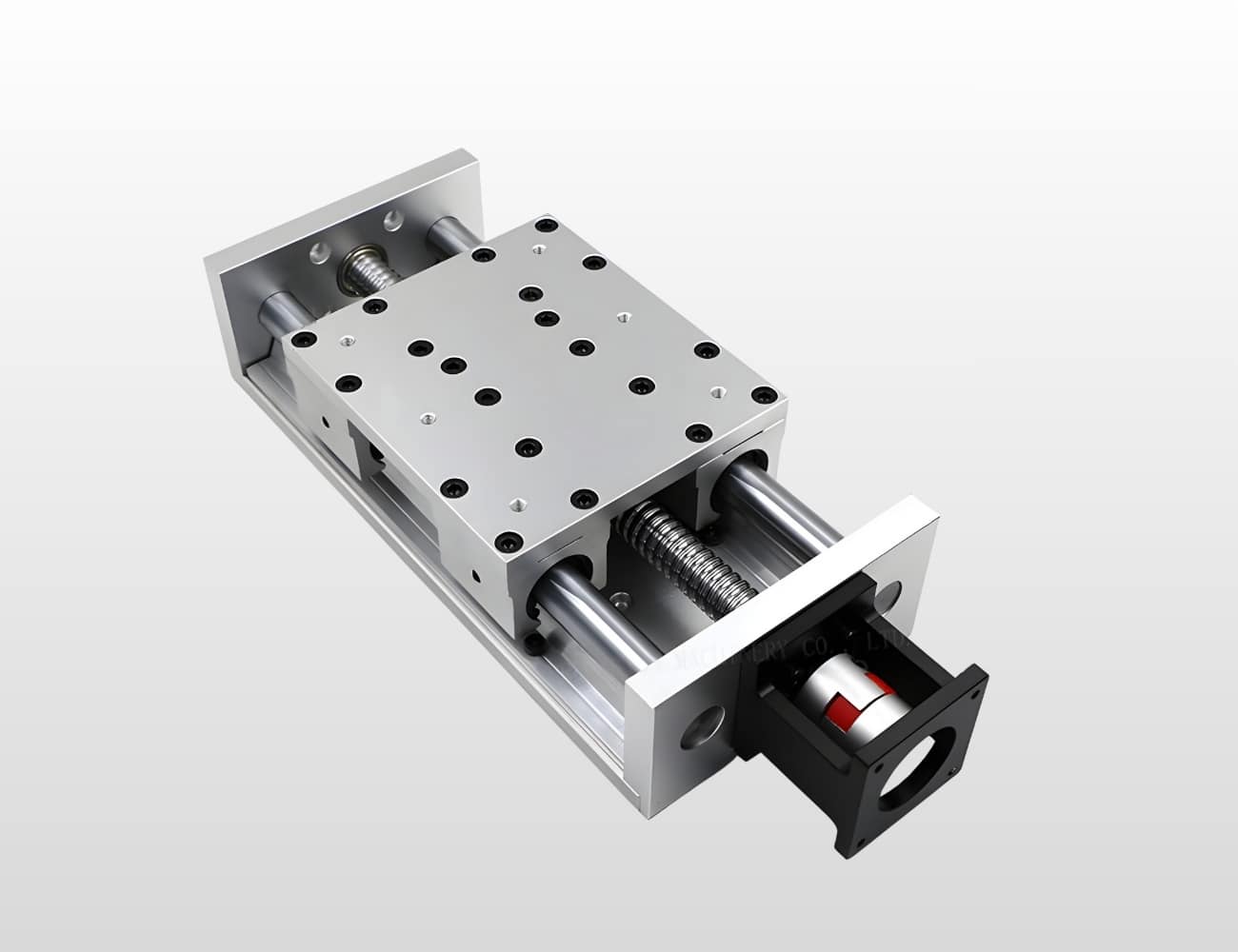

O que são componentes de movimento linear?

Os componentes de movimento linear são peças maquinadas com precisão que permitem o movimento em linha reta controlado em equipamento automatizado. Estes componentes incluem calhas de guia lineares, blocos deslizantes, caixas de rolamentos, corpos de actuadores, fases de posicionamento, porcas de fusos de esferas e suportes de montagem utilizados em máquinas CNC, sistemas de recolha e colocação, impressoras 3D, equipamento de manuseamento de materiais e linhas de montagem automatizadas. Cada componente deve proporcionar um movimento suave, manter a exatidão posicional, suportar a capacidade de carga e resistir ao desgaste através do funcionamento contínuo. A qualidade dos componentes de movimento linear de precisão tem um impacto direto na precisão do sistema, nas capacidades de velocidade e nos requisitos de manutenção em todas as aplicações de automação.

Principais requisitos técnicos

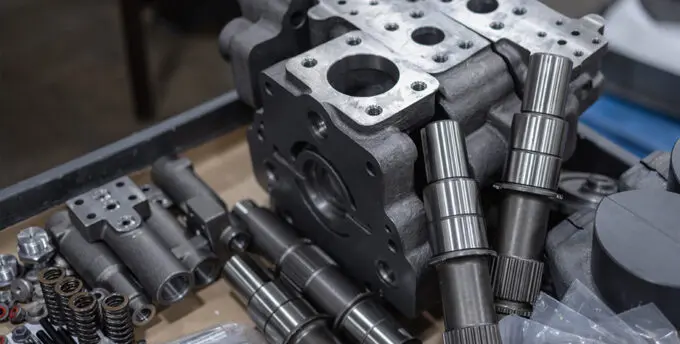

O fabrico de componentes de movimento linear exige uma precisão e uma qualidade de superfície excepcionais. As tolerâncias típicas variam de ±0,005″ para caraterísticas de montagem até ±0,0005″ para pistas de rolamentos, superfícies de guia e dimensões críticas que asseguram um funcionamento suave e um ajuste correto. As especificações do material incluem aço temperado (52100, 440C) para superfícies de apoio, ligas de alumínio (6061-T6, 7075-T6) para carruagens ligeiras, aço inoxidável (304, 316, 440C) para ambientes corrosivos, e aço para ferramentas (D2, A2) para aplicações resistentes ao desgaste.

Os requisitos de acabamento da superfície são críticos para a qualidade do movimento. As superfícies das guias precisam de Ra 16 micropolegadas ou mais suave para um atrito reduzido e um deslocamento suave. As áreas de contacto dos rolamentos requerem Ra 8 micropolegadas com uma dureza de superfície adequada para uma longa vida útil. Os componentes lineares devem manter retilinearidade com uma tolerância de 0,0005″ por pé, paralelismo entre as superfícies de guia dentro de 0.001″A superfície de montagem deve ser plana e os bordos de referência devem ser perpendiculares. Os componentes devem suportar cargas de 10 a mais de 5.000 libras dependendo da conceção, funcionamento a alta velocidade até 10 pés por segundoforças de aceleração e estabilidade de temperatura de 32°F a 150°F para evitar problemas de expansão térmica que afectem a precisão.

Desafios e soluções para o fabrico

A maquinagem de componentes de movimento linear apresenta desafios técnicos únicos. A obtenção de tolerâncias de retilinearidade apertadas em comprimentos longos requer máquinas-ferramentas rígidas e estabilidade térmica. Múltiplas superfícies paralelas ou perpendiculares com relações geométricas apertadas exigem uma configuração e medição precisas. Os materiais duros necessários para a resistência ao desgaste criam desgaste da ferramenta e geração de calor. A manutenção de um excelente acabamento superficial, mantendo um controlo dimensional rigoroso, requer processos especializados.

A Yicen Precision supera estes desafios com capacidades de fabrico avançadas. Os nossos equipamento de retificação de precisão produz superfícies de guia com uma retidão, paralelismo e acabamento de superfície excecionais que a fresagem por si só não consegue alcançar. Centros de maquinagem CNC de 5 eixos lidar com geometrias complexas e múltiplas caraterísticas de montagem em configurações coordenadas. Utilizamos fixação de precisão com ambientes de temperatura controlada para estabilidade térmica durante a maquinagem de componentes longos.

O controlo de qualidade garante que os componentes de movimento linear cumprem todos os requisitos de desempenho. Inspeção CMM verifica a retidão utilizando vários pontos de medição ao longo das superfícies de guia. Perfilometria de superfície confirma que a qualidade do acabamento corresponde às especificações. Medimos paralelismo e perpendicularidade utilizando indicadores de precisão e superfícies de referência em granito. Ensaio de dureza verifica os resultados do tratamento térmico. Cada componente de movimento linear recebe relatórios dimensionais, verificação de tolerâncias geométricas, dados de acabamento de superfícies e certificações de materiais garantir a total conformidade com os requisitos do sistema de movimento e com as normas de qualidade ISO.

Aplicações e casos de utilização

Os componentes de movimento linear maquinados com precisão desempenham funções essenciais em diversas aplicações de automação:

- Máquinas-ferramentas CNC: Guias lineares, blocos de suporte de parafusos de esferas e componentes de deslizamento para centros de maquinagem, tornos e máquinas EDM

- Sistemas Pick-and-Place: Caixas de actuadores lineares de alta velocidade, blocos de guia e estágios de posicionamento para montagem e embalagem de produtos electrónicos

- Equipamento de impressão 3D: Carris de movimento linear, blocos de carros e componentes de posicionamento para sistemas de fabrico aditivo

- Manuseamento de materiais: Conjuntos de corrediças lineares, sistemas de carris de transferência e guias de precisão para sistemas de transporte e equipamento de triagem

- Fabrico de semicondutores: Estágios lineares de ultra-precisão e componentes de posicionamento para equipamentos de manuseamento e inspeção de bolachas

- Montagem de dispositivos médicos: Componentes de movimento linear compatíveis com o ambiente limpo para sistemas automatizados de fabrico e teste de dispositivos médicos

- Inspeção automatizada: Estágios de varrimento linear, sistemas de posicionamento de precisão e componentes de movimento para inspeção visual e equipamento de controlo de qualidade

Porquê escolher a Yicen Precision para componentes de movimento linear?

A Yicen Precision é especializada na maquinagem CNC de componentes de movimento linear de precisão com prazos de entrega tão curtos como 1-2 semanas para componentes padrão e 3-4 semanas para projectos personalizados que exijam retificação ou processamento especializado. O nosso fabrico flexível suporta tanto o desenvolvimento de protótipos para novos sistemas de movimento como quantidades de produção de 10 a mais de 500 unidades para construtores de equipamento e OEMs.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos em termos de retilinearidade e paralelismo, orientação da seleção de materiais para requisitos específicos de carga e velocidade e recomendações de tratamento de superfícies para resistência ao desgaste. A nossa documentação de qualidade inclui relatórios detalhados de inspeção geométrica, medições de acabamento de superfícies, resultados de testes de dureza e certificações de materiais que suportam a conformidade com a norma ISO 9001.

A nossa abordagem económica tira partido de sequências de maquinação eficientes, capacidades de retificação internas e fornecimento estratégico de materiais para oferecer preços competitivos. Compreendemos que os componentes de movimento linear requerem uma precisão que afecta diretamente o desempenho e a precisão do sistema. Quer esteja a construir equipamento de recolha e colocação de alta velocidade, máquinas-ferramentas de precisão ou sistemas de automação personalizados, a nossa experiência assegura que os seus componentes de movimento linear proporcionam a suavidade e fiabilidade que as suas aplicações exigem. Contacte-nos hoje para obter uma consulta técnica e orçamentos rápidos para os seus requisitos de fabrico de componentes de movimento linear.