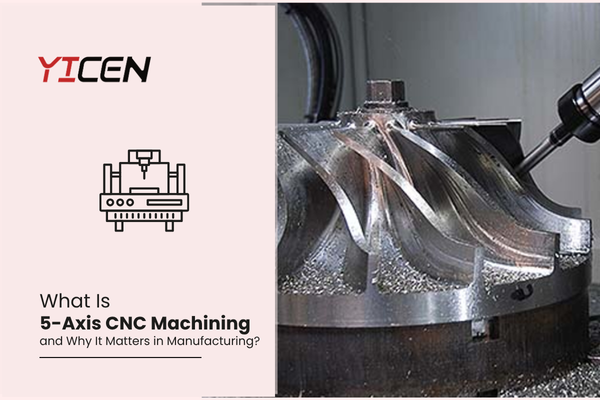

The 5-axis CNC machining is an innovative technology and is used in manufacturing of parts that require high demands in a very precise manner. This technology enables the tools to move in five directions unlike the traditional machines. These directions consist of the normal X, Y, and Z but have two rotational axes that are A and B. This versatility helps the manufacturers to place many sides of a part on a single set up. It makes handling reliable, error-free results, and faster.

The manufacturers want it because it can allow the manufacture of deep-angled and curved parts. It is applied in the fields that require perfection such as aerospace, car industries and medicine. Components that are produced by the 5-axis CNC machining are stiff, smooth, and precise. This is the best option in case your project is highly precise and complex.

How Does 5-Axis CNC Machining Work?

In traditional 3-axis machining, the tool only moves in three straight lines: X (left-right), Y (front-back), and Z (up-down). But 5-axis CNC machining goes beyond that. It adds two more directions by rotating around the X and Y axes. These are known as the A and B axes. The result is a tool that can approach the material from nearly any direction.

This ability changes everything. It lets you machine complex shapes without repositioning the part manually. That means fewer errors and faster production. You can cut undercuts, sharp curves, and deep cavities with ease. All of this is done in a single setup, improving both accuracy and efficiency.

Why Use 5-Axis CNC Machining for Complex Parts?

In case your pieces are intricate, rounded or geometrically complex then 5-axis CNC machining is the one to go with. It is designed for work that simpler machines cannot handle. This technique does not disappoint whether you are doing turbine blades, orthopedic implants, or mold components.

The method is especially valuable in industries where accuracy is crucial. Aerospace engineers use it for light but strong parts. Medical manufacturers depend on it to produce implants with smooth edges and perfect fits. In the automotive world, it helps build performance-critical engine and brake components.

Key Differences Between 3-Axis and 5-Axis CNC Machining

| Feature | 3-Axis CNC | 5-Axis CNC Machining |

| Axes of Movement | X, Y, Z | X, Y, Z + A, B |

| Setup Time | Multiple setups | Minimal setups |

| Machining Angle | Limited | Multi-directional |

| Precision for Complex Parts | Lower | Very high |

| Ideal For | Simple shapes | Complex and curved designs |

This comparison shows why many companies are moving to 5-axis systems. You can cut more parts in less time with greater precision.

When Should You Choose 5-Axis CNC Machining?

You should consider this method when your product design requires tight tolerances and smooth finishes. It’s perfect for industries like:

Aerospace: Components like turbine blades, housings, and brackets demand precision and reliability.

Medical: Implants, surgical tools, and instruments must fit the human body precisely.

Automotive: Engine heads, intake manifolds, and brake systems need accurate geometry.

The selection of this technology decreases the mistakes and provides repeatability. Being in the position of producing one prototype or hundreds of units, 5-axis machining produces the best results each and every time.

What Are the Benefits of 5-Axis CNC Machining?

The advantages go far beyond just having more directions for tool movement. It impacts the full manufacturing process in positive ways.

Shorter Lead Times: No need to stop and reset the material between operations. This means faster production from start to finish.

Improved Surface Finish: Tools can maintain better alignment with curved surfaces. This reduces the need for hand finishing later.

Reduced Tool Wear: Cutting at optimal angles reduces stress on tools, which means they last longer and work better.

In summary, you get faster production, better quality, and lower costs all in one package.

Applications of 5-Axis CNC Machining by Industry

| Industry | Application Examples | Benefits of 5-Axis Machining |

| Aerospace | Wing spars, turbine blades | Lightweight parts, extreme accuracy |

| Medical | Implants, surgical instruments | Smooth finishes, perfect curvature |

| Automotive | Engine blocks, brake calipers | Tight tolerances, performance-ready parts |

| Tool & Die | Injection molds, die models | Reduced cycles, better surface finish |

| Defense | Weapon frames, tactical parts | Strength, reliability, high precision |

As you can see, this method is valuable across many high-demand sectors. It solves complex manufacturing challenges with ease.

Who Uses 5-Axis CNC Machining?

The users of this method range from large corporations to small workshops. OEMs and component makers turn to it for accurate results. Even tech startups and research labs use it for prototypes.

If you are looking for expert services in multi-axis machining, Yicen is a trusted name in the industry. We provide 5-axis CNC machining for clients worldwide. Whether you need one part or thousands, we can deliver with speed and quality.

Why 5-Axis CNC Machining Beats Other Methods

Let’s compare this technique with other popular machining approaches:

- Compared to 3-Axis CNC: 5-axis can do the job in fewer setups. That saves time and increases dimensional accuracy.

- Compared to Manual Machining: There’s no risk of human error. Machines follow exact programmed paths every time.

5-axis technology also gives access to hard-to-reach surfaces, which manual or 3-axis methods can’t achieve. This flexibility is why so many industries are switching.

What Makes Multi-Axis Machining So Special?

Multi-axis machining (including 4- and 5-axis types) gives unmatched flexibility and control. It allows more complex geometries to be made faster. The tool can maintain optimal cutting positions, improving tool life and finish quality.

Modern parts are becoming smaller, lighter, and more detailed. The only way of accommodating these new demands is through multi-axis machines. This is why they are the preferred ones in the high-level technology and performance-oriented projects.

Which Software Powers 5-Axis CNC Machines?

Advanced software is essential for making the most of 5-axis machines. Some popular programs include:

- Mastercam: Known for its easy interface and powerful simulation tools.

- Fusion 360: A favorite among designers and small shops for its integrated CAD/CAM functions.

- SolidCAM: Offers full 5-axis support with intelligent toolpath strategies.

Those programs assist in avoiding collisions and free movements of the tools. The correct hardware is also essential as the correct software.

How to Choose the Right Machining Service?

When searching for the best service provider, check the following:

- Proven experience in working with complex, multi-surface parts.

- Access to advanced machines and well-trained staff.

- Strong quality control systems in place.

Yicen meets all of these standards. We specialize in 5-axis machining and deliver world-class services. Our customers rely on our quality of precision, swiftness and low prices.

What Are the Limitations of 5-Axis CNC Machining?

While this technology is powerful, it’s not without challenges. First, the machines and software are expensive. They require skilled programmers to create effective tool paths. Training and maintenance also add to the costs. But these disadvantages are compensated by the advantages: a reduced number of set-ups, cheap labor, and increased accuracy. To most companies, the long-term benefits are worth the cost of the investment.

Conclusion

5-axis CNC machining has transformed modern manufacturing. It enables complex parts to be produced quicker, precisely, and efficiently. It is suitable in those industries that require perfection as the finishing and where the number of setups are fewer. Be it in the aerospace industry, automotive industry or medical, the benefits of this approach are incomparable. It is the right combination of speed, power and precision. Major companies such as Yicen are assisting businesses to achieve high quality standards by offering quality and dependable 5-axis. Want to reduce your expenses, save your time, and increase the quality? It is time to switch.

FAQs

Is it possible to handle large parts with 5-axis machining?

Yes, some machines are built to manage long and heavy parts with ease.

Is 5-axis CNC machining expensive?

Initial setup costs are high, but it reduces time and waste, saving money long term.

What materials can be used?

Common choices include aluminum, titanium, stainless steel, composites, and plastics.

Do you need special software for this?

Yes, 5-axis machining requires dedicated CAM software for accurate control and simulation.