The manufacturing world has changed dramatically. Where traditional manufacturing methods once dominated, Metal 3d printing technology now creates parts that seemed impossible just years ago. This shift isn’t just about fancy gadgets – real companies are using metal 3D printing service to solve actual production challenges.

Take Boeing’s fuel nozzles or the custom titanium implants saving lives in hospitals. These aren’t prototypes gathering dust on shelves. They’re functional parts working in demanding applications every single day. Yicen Precision understands this reality, combining their additive manufacturing expertise with traditional CNC machining services to deliver custom parts that actually work.

How Metal 3D Printing Actually Works

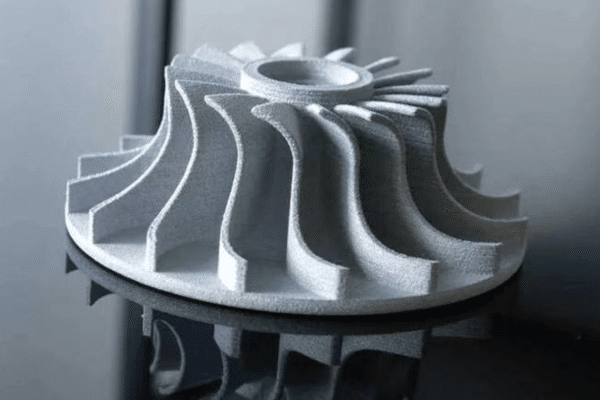

Most people think 3d printing metal sounds like science fiction. The reality is much more straightforward. A metal 3d printer spreads thin layers of metal powder across a build platform. Then a laser selectively melts specific areas, creating solid metal parts one layer at a time.

Different 3d printing processes handle this basic concept in various ways. Direct metal laser sintering (DMLS) partially melts powder particles, while selective laser melting completely liquefies the metal powder particles. Binder jetting takes a different approach entirely, using liquid binder to hold loose powder together before sintering.

The printing process itself might take hours or days depending on part size. What happens after printing often matters more than the actual printing. Heat treatment relieves stress, sinter operations densify parts, and careful post-processing achieves the right surface finish.

Materials That Actually Matter

- Stainless steel dominates many applications because it works. The 316L alloy resists corrosion while maintaining decent strength. When higher performance is needed, 17-4 PH stainless offers better tensile strength after heat treatment.

- Titanium costs more but delivers exceptional strength-to-weight ratios. The Ti-6Al-4V alloy serves both aerospace components and medical implants. Its biocompatibility makes it valuable for parts that contact human tissue.

- Inconel handles extreme temperatures that melt other metals. Jet engines rely on this superalloy for turbine blades and combustor parts. The hardness and corrosion resistance justify the premium price for critical applications.

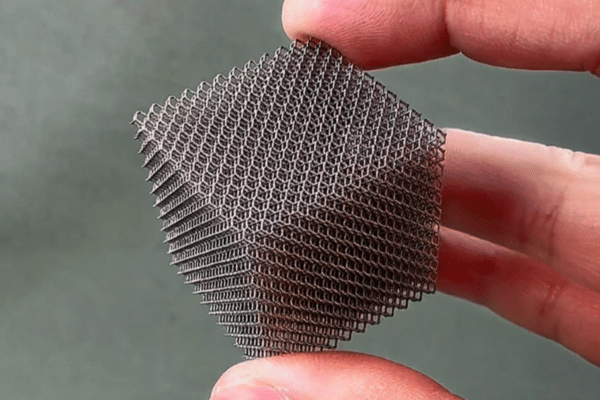

- Tool steel varieties like H13 and D2 create durable parts for manufacturing equipment. These metal alloys maintain their properties under repeated stress cycles. Die casting molds and injection molding tools benefit from the complex cooling channels possible with additive manufacturing technology.

3d printing material selection depends on intended use. Aluminum alloys work well for automotive prototypes requiring good thermal conductivity. Filament-based systems using bound metal powder offer safer handling than loose powder approaches.

Real Equipment Doing Real Work

3d Systems builds some of the most reliable metal 3d printing systems available. Their DMP series handles everything from small aerospace components to large production parts. The Markforged Metal X system takes a different approach, extruding metal-filled filament instead of working with loose powder.

Industrial 3d printing equipment costs serious money. A quality dmls metal system might cost half a million dollars or more. However, the ability to produce parts with complex geometries often justifies the investment.

Metal printers require careful environmental controls. Industrial metal processing creates safety hazards that desktop printers never face. Explosive metal powder, toxic fumes, and intense heat demand proper safety protocols.

The Metal X system from Markforged offers a safer alternative. Their bound powder approach eliminates many safety concerns associated with traditional powder-based systems. Parts still require washing and sintering, but handling risks decrease significantly.

Where This Technology Thrives

- Aerospace applications showcase metal 3d printing at its best. Complex internal cooling channels in turbine blades improve efficiency while reducing weight. These functional parts couldn’t exist without additive manufacturing.

- Automotive companies use metal 3d printing differently. Rapid prototyping accelerates design cycles, while custom 3d tooling improves manufacturing processes. Racing teams create lightweight brackets and housings impossible with traditional manufacturing.

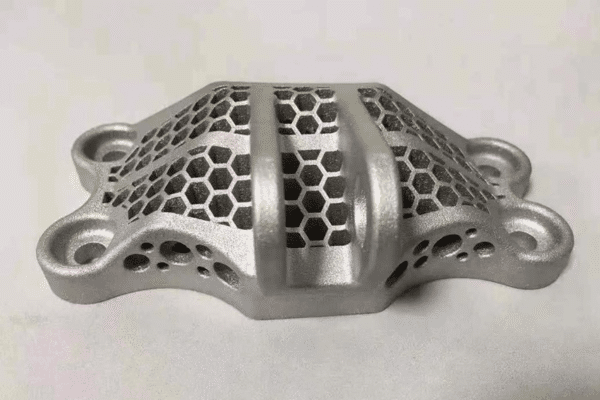

- Medical applications demand both precision and biocompatibility. metal 3d printing parts match patient anatomy exactly while using materials the body accepts. Hip implants with porous surfaces encourage bone growth, improving long-term success rates.

- Industrial 3d applications often focus on replacement parts. When a critical machine component fails, 3d printing service providers can recreate it from drawings or scans. This capability keeps production lines running when original parts aren’t available.

Production Realities

3d printing can produce virtually any shape, but economics matter. End-use parts in small quantities make sense. Production parts in thousands might favor traditional manufacturing methods depending on complexity.

DMLS parts typically cost more per piece than machined equivalents at high volumes. However, the break-even point shifts when parts require multiple machining setups or complex assembly operations.

Build metal parts economics improve with quantity up to a point. Packing multiple parts into a single build spreads fixed costs across more pieces. Beyond certain volumes, traditional manufacturing regains cost advantages.

Material properties of 3d printed metal parts often match or exceed wrought equivalents. Proper additive manufacturing process parameters create parts with excellent tensile strength and fatigue resistance.

Service Selection Strategy

Get an instant quote sounds appealing, but quality providers need time to evaluate projects properly. Metal 3d printing include many variables that affect cost and feasibility. Rush quotes often miss critical details.

Experience with similar applications matters more than equipment specifications. A provider who has successfully produced aerospace components understands the quality standards required. Their portfolio of 3d projects demonstrates capability better than marketing materials.

Printing platforms vary significantly in capability and cost. High-end dmls metal systems produce better surfaces and tighter tolerances than entry-level equipment. The application determines whether premium capabilities justify higher costs.

Range of metals available through a service provider affects design flexibility. Some specialize in specific metal alloys while others offer broader material selections. 3d printable materials continue expanding as technology matures.

Why Choose Integrated Manufacturing

Use metal 3d printing where it excels, but recognize its limitations. Fused filament fabrication works for prototypes but rarely for production of metal parts. Direct metal processes handle end-use applications better.

Yicen Precision combines 3d printing technology with conventional machining. This hybrid approach leverages additive manufacturing for complex geometry while using machining for critical surfaces. Custom parts often benefit from both processes.

Traditional manufacturing still excels in many applications. Metal components requiring exceptional surface finish or extreme precision might need conventional processes. Smart manufacturers choose the right tool for each application.

Process Limitations Worth Understanding

Limitations of metal 3d printing include support requirements and surface finish challenges. Overhanging features need supports that leave marks after removal. Layer by layer construction creates surfaces with characteristic textures.

Mechanical properties vary with build direction in some metal 3d printing processes. Parts may show different strength along versus across layer lines. Design orientation affects performance in critical applications.

Production of metal parts through additive manufacturing requires more post-processing than many realize. Sinter operations, support removal, and heat treatment add time and cost to finished parts.

Corrosion resistance and other material properties depend on proper processing. Incomplete melting or contamination can degrade performance. Quality control becomes critical for demanding applications.

Future Directions

Metal additive manufacturing continues evolving rapidly. Printing metal with multiple materials in single builds opens new possibilities. Industrial 3d printing equipment becomes more automated and reliable each year.

Produce parts economics improve as technology matures. Metal 3d printing can produce parts economically at lower volumes than ever before. This trend favors customization over mass production in many markets.

3d metal printing applications expand into new industries as capabilities improve. What seems experimental today becomes routine production tomorrow. Early adopters gain advantages that compound over time.

Conclusion

Metal 3d printing service has moved beyond hype to deliver real value. Companies now 3d print critical functional parts for demanding applications. Success requires understanding both capabilities and limitations.

The technology works best for complex geometries, custom parts, and low-volume production. Traditional manufacturing remains superior for high volumes and simple shapes. Smart manufacturers use both approaches strategically.

3d printing can produce complex parts impossible through conventional means. This capability opens design possibilities that didn’t exist before. Combined with traditional processes, it creates new opportunities for innovation and efficiency.

Frequently Asked Questions

What makes DMLS different from other metal 3D printing methods?

Can 3D printed metal parts match the strength of traditional manufacturing?

Which industries benefit most from metal 3D printing services?

How do you choose between different metal 3D printing technologies?

What post-processing do metal 3D printed parts need?

Citations:

¹ National Institute of Standards and Technology. (2025). “Additive Manufacturing.” NIST. Retrieved from https://www.nist.gov/additive-manufacturing