What Is SLS Printing and Why Does It Matter?

SLS printing represents a revolutionary 3d printing process that uses a high-powered laser to selectively fuse powdered materials into functional objects. This selective laser sintering additive manufacturing process creates prototypes and end-use parts without traditional tooling requirements.

The sintering process works when a laser traces each layer of powder while heating particles to their melting point. These particles bond together forming solid 3d printed parts. This powder bed fusion approach eliminates design constraints found in conventional manufacturing methods.

Yicen Precision specializes in advanced sls 3d printing alongside comprehensive precision manufacturing services. Their 3d printing service covers multiple sls materials for various industrial 3d printing applications.

How SLS Printing Technology Works?

The Complete SLS Process

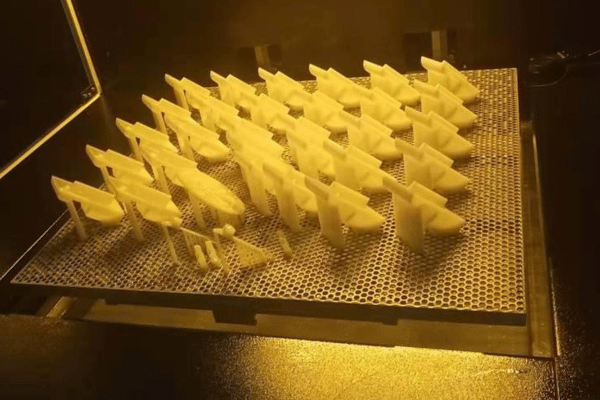

SLS printing begins with 3d models converted into printable layers through specialized software. Sls machines maintain precise temperatures between 80°C and 200°C depending on printing material requirements. The co₂ laser system delivers 25-100 watts of power while laser scanning at speeds reaching 12 meters per second.

Sls systems achieve precise beam diameters around 0.4 millimeters for detailed work. Sls post-processing removes unsintered powder, with recovery systems recycling up to 95% of unused material, making this additive manufacturing method economically sustainable.

Key Components of SLS Systems

| Component | Function | Quality Impact |

| High-power laser | Uses a laser to fuse particles | Controls resolution and strength |

| Powder Handling | Distributes powdered material | Affects surface finish |

| Temperature Control | Maintains thermal stability | Prevents warping |

| Powder bed | Supports construction | Ensures accuracy |

Why SLS Printing Excels Over Other Methods?

Superior Design Freedom

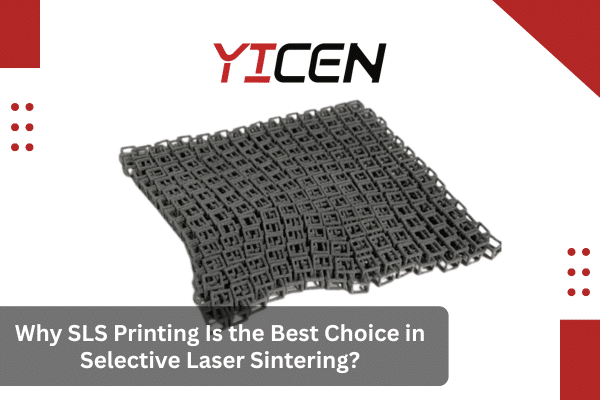

SLS printing creates complex internal channels and interlocking assemblies within single builds. Unlike injection molded parts, sls technology enables wall thickness down to 0.8 millimeters while maintaining structural integrity and optimal strength-to-weight ratios.

Selective laser sintering 3d printing produces uniform mechanical properties in all directions, unlike 3d printing technologies like fdm that show weakness between layers. The advantages of sls include eliminating support structures for most geometries.

Material Versatility and Performance

Additive manufacturing technologies through sls 3d printing accommodate engineering-grade thermoplastics, elastomers, and metal 3d printing materials. Yicen Precision maintains extensive libraries of sls materials including certified aerospace and medical-grade options for rapid prototyping applications.

Materials Available for SLS Printing

Polymer Materials

Sls nylon dominates applications with 45 MPa tensile strength and 20% elongation at break. Glass-filled nylon variants increase stiffness by 300% while maintaining impact resistance for demanding end-use parts.

TPU enables flexible sls 3d printed parts with Shore A hardness from 80 to 95. These materials withstand over 100,000 flexing cycles, proving ideal for functional prototypes and production components.

Metal Materials

Direct metal laser sintering with stainless steel 316L achieves 99% density and 570 MPa tensile strength after heat treatment. Aluminum alloys offer excellent thermal conductivity while maintaining competitive strength-to-weight ratios for metal 3d applications.

Advantages of SLS Printing Technology

Cost-Effective Production

SLS printing eliminates expensive tooling with break-even points around 1,000 units compared to other 3d printing methods and traditional manufacturing. This printing technology reduces waste while enabling part consolidation.

Yicen Precision offers competitive sls 3d printing pricing through efficient production planning alongside cnc machining services for hybrid manufacturing processes.

Quality and Precision Benefits

| Method | Setup Time | Design Changes | Complexity |

| Traditional | 4-12 weeks | Expensive | Limited |

| SLS 3D Printing | 1-3 days | Software only | Unlimited |

Powder bed fusion 3d printing achieves ±0.3% dimensional tolerances with surface finish quality from Ra 6-12 micrometers. This selective laser sintering process delivers consistent results across a variety of materials.

Applications Across Industries

Aerospace and Defense

Boeing and Airbus have certified numerous sls parts for commercial aircraft applications. Industrial 3d printing creates lightweight brackets and complex manifolds meeting stringent aerospace requirements through this advanced manufacturing process.

Yicen Precision serves aerospace clients with AS9100-certified precision manufacturing and quality control systems for critical 3d printed components.

Medical Device Manufacturing

Medical applications use sls for patient-specific implants and surgical instruments using biocompatible sls materials. Dental applications achieve 50-micrometer accuracy for crowns and orthodontic appliances through this precise additive manufacturing process.

Automotive Industry

Ford Motor Company uses additive manufacturing for over 500,000 prototyping applications, reducing development costs by 75%. Sls technology produces air intake manifolds and electrical housings leveraging complex geometries impossible with traditional methods.

SLS vs Other 3D Printing Technologies

SLS vs FDM Printing

SLS printing eliminates support structures while achieving superior surface finish and mechanical properties compared to fused deposition modeling. Selective laser sintering creates isotropic 3d printed parts with consistent strength regardless of orientation.

Fdm systems cost less initially but sls offers better functionality for end-use parts requiring engineering-grade performance.

SLS vs SLA Printing

SLS printing produces ready-to-use parts immediately after powder removal, while sla requires extensive washing and UV curing. Laser sintering materials offer better temperature resistance and durability for functional applications.

Quality Control in SLS Printing

Process Monitoring

Modern sls printers incorporate thermal imaging and laser power monitoring during production cycles. Statistical process control tracks dimensional variation across batches of sls 3d printed parts.

Yicen Precision implements comprehensive quality control including first article inspection and periodic verification exceeding industry requirements for 3d printing technologies.

Testing and Validation

Material certification involves mechanical testing of specimens built alongside production sls parts. Non-destructive methods including CT scanning verify internal quality for critical additive manufacturing applications.

Future Trends in SLS Printing

Technology Advancements

Multi-laser configurations increase sls production speeds while maintaining quality standards. Machine learning optimizes selective laser sintering parameters automatically, reducing setup time and improving yield rates for 3d printing methods.

New materials including continuous fiber reinforcement expand metal 3d printing into markets previously dominated by traditional manufacturing methods.

Market Growth Projections

Powder bed fusion technology shows compound annual growth exceeding 15% through 2030. According to NIST research, additive manufacturing adoption accelerates as design tools improve and workforce training programs expand [^1].

Choosing the Right SLS Service Provider

Key Selection Criteria

Evaluate sls 3d printing providers based on equipment capabilities, material certifications, and ISO 9001 quality systems. Technical support determines successful outcomes for complex industrial 3d printing applications.

Yicen Precision provides comprehensive 3d printing services backed by manufacturing experience and certified quality systems supporting both prototyping and production needs.

Service Quality Indicators

Material traceability ensures sls materials meet specifications for regulatory compliance. Dimensional inspection reports demonstrate process capability with statistical analysis across production batches of 3d printed parts.

Conclusion

SLS printing delivers unmatched capabilities for complex, functional components across industries. This selective laser sintering technology combines design freedom with production-ready materials, making it essential for modern additive manufacturing.

Yicen Precision provides expert sls 3d printing with comprehensive quality control and precision manufacturing capabilities. The technology’s advancement promises broader adoption reshaping manufacturing processes.

What materials work best for SLS printing?

How accurate is SLS printing technology?

What are the size limitations for SLS printing?

How long does SLS printing take?

What industries benefit most from SLS printing?

Citations

[^1]: National Institute of Standards and Technology. “Additive Manufacturing: Status and Opportunities.” NIST Special Publication 1176. https://www.nist.gov/publications/additive-manufacturing-status-and-opportunities

Additional References:

- Gibson, I., Rosen, D., Stucker, B., & Khorasani, M. (2021). Additive Manufacturing Technologies. Springer International Publishing.

- ASTM International. “Standard Terminology for Additive Manufacturing Technologies.” ASTM F2792-12a.

- Wikipedia Contributors. “Selective Laser Sintering.” Wikipedia, The Free Encyclopedia. https://en.wikipedia.org/wiki/Selective_laser_sintering

- International Organization for Standardization. “Additive Manufacturing – General Principles.” ISO/ASTM 52900:2015.

- U.S. Department of Energy. “Additive Manufacturing: Pursuing the Promise.” DOE Advanced Manufacturing Office, 2023.