Are you diving into the world of precision manufacturing and wondering about the nuances between CNC turning and milling? These two processes form the backbone of modern machining, each excelling in specific scenarios. In this in-depth guide, we’ll explore their mechanics, differences, advantages, disadvantages, applications, costs, common pitfalls, and future trends. Whether you’re a hobbyist, engineer, or business owner in industries like automotive or aerospace, understanding these can help you make informed decisions. We’ll draw on real-world examples, recent data from 2025-2026, and practical tips to give you a complete picture.

Understanding CNC Turning: The Basics and Beyond

CNC turning is a subtractive manufacturing process where a workpiece rotates at high speeds while a stationary cutting tool removes material to create cylindrical or conical shapes. Imagine shaping a spinning piece of clay on a potter’s wheel—that’s turning in essence, but with computer precision.

How It Works in Detail

The process starts with securing the material (often a bar or rod) in a chuck on a lathe. The lathe spins the workpiece at speeds ranging from 1,000 to 4,000 RPM, depending on the material. The cutting tool, mounted on a turret, moves linearly along the X and Z axes (and sometimes Y for advanced machines) to shave off layers. For intricate parts, live tooling allows milling-like operations while the piece rotates.

This rotational motion ensures symmetry, making it ideal for parts like shafts or bushings. In a real scenario, producing an automotive piston involves turning the outer diameter first, then threading or grooving.

Key Tools and Machines

Standard CNC lathes are 2-axis, but turning centers can have up to 12 axes with sub-spindles for dual-sided work. Tools include carbide inserts for durability—lasting up to 500 parts before replacement in high-volume runs. Swiss-style lathes, popular in medical manufacturing, slide the workpiece through a guide bushing for ultra-precise, long slender parts.

Best Materials and Why

Soft metals like aluminum (easy to cut, low tool wear) and brass excel here, as do plastics like Delrin for its machinability. Harder materials like titanium, used in aerospace for its strength-to-weight ratio, require slower speeds to avoid heat buildup. Why? Excessive heat can warp the part or dull tools quickly.

Pro Tip: Always calculate chip load (material removed per tool revolution) to optimize speed—too high, and you’ll get rough finishes; too low, and production drags.

Understanding CNC Milling: A Deeper Dive

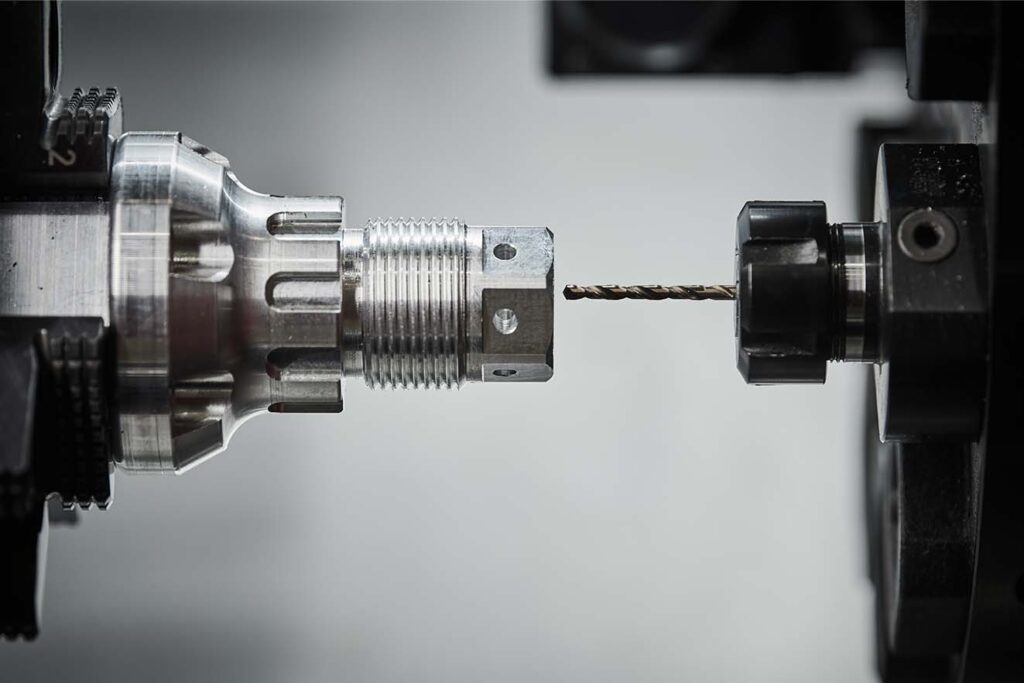

CNC milling flips the script: the workpiece stays fixed (or moves linearly), while a rotating tool removes material from multiple angles. It’s like sculpting with a high-speed drill, perfect for complex, non-symmetrical parts.

How It Works in Detail

The machine uses a spindle to rotate tools at 5,000-20,000 RPM. The table moves in X, Y, and Z axes; advanced 5-axis mills add A and B for rotation, enabling undercuts without repositioning. Material is removed in passes—roughing for bulk removal, then finishing for smooth surfaces down to 0.001-inch tolerances.

For example, milling an engine block involves pocket milling for cavities and contouring for curves. Hybrid mill-turn machines combine both for one-setup efficiency.

Key Tools and Machines

3-axis mills handle basic flats; 5-axis for aerospace impellers. Tools like end mills (for slots) and ball mills (for curves) are common, often coated with titanium nitride for longevity. Vertical mills are space-efficient; horizontal for heavy cuts.

Best Materials and Why

Harder alloys like stainless steel thrive here due to the tool’s stability. Composites in electronics resist cracking better in milling. Why? The fixed workpiece minimizes vibration, preserving detail in brittle materials.

Expert Advice: Use adaptive clearing strategies in CAM software to maintain constant tool engagement, reducing wear by up to 40%.

Core Similarities: What Unites Them

Both are CNC-controlled for repeatability, using CAD/CAM for design-to-part flow. They achieve tolerances as tight as ±0.0005 inches and handle volumes from prototypes to thousands. Shared in industries like automotive (e.g., gears) and medical (implants), they prioritize safety with enclosures and coolant systems.

Key Differences: Breaking It Down

The fundamental split is motion: turning rotates the part; milling rotates the tool. This affects everything.

| Aspect | CNC Turning | CNC Milling |

| Motion | Workpiece rotates | Tool rotates |

| Shapes | Cylindrical, conical (e.g., shafts) | Prismatic, 3D complex (e.g., brackets) |

| Speed | Faster for rounds (10-20 min/part) | Versatile but slower (30-60 min/part) |

| Axes | 2-5 typically | 3-5+ for multi-angle |

| Waste | Lower for symmetric parts | Higher due to chips |

| Setup Time | Quicker for bars | Longer for fixturing |

Turning suits high-volume rounds; milling for low-volume customs.

Pros and Cons of CNC Turning

Advantages

- Speed: Up to 50% faster for cylindrical parts.

- Cost-Effective: Lower tooling needs; ideal for batches over 1,000.

- Precision: Excellent surface finishes (Ra 0.4-1.6 µm).

- Example: In automotive, turning pistons reduces material waste by 30%.

Disadvantages

- Shape Limits: Struggles with flats or slots without add-ons.

- Vibration: Long parts can chatter, needing steady rests.

- Higher Setup for Complex: Multi-tool changes slow things.

Turning excels when symmetry is key, like transportation axles.

Pros and Cons of CNC Milling – In-Depth Explanation

CNC milling is one of the most versatile subtractive manufacturing processes available today. It uses rotating multi-point cutting tools to remove material from a stationary (or moving) workpiece, allowing for highly detailed and complex parts. Below is a detailed breakdown of its advantages and disadvantages, expanded with explanations, real-world context, practical implications, and examples relevant to industries like medical devices, electronics, aerospace, and automotive manufacturing (as of 2026 trends).

Advantages of CNC Milling

- Exceptional Versatility for Complex Geometries CNC milling excels at producing intricate 3D shapes, deep pockets, slots, threads, undercuts, contours, and free-form surfaces that are difficult or impossible with other methods like turning.

-

- Why it matters: Multi-axis machines (especially 4- or 5-axis) allow the tool to approach the workpiece from almost any angle without repositioning the part multiple times. This reduces setup errors and enables true undercuts or compound curves.

- Real example: In electronics manufacturing, milling creates precise PCB enclosures with integrated heat sinks, mounting bosses, and intricate cooling channels in one setup. In medical devices, it produces custom orthopedic implants with porous surfaces for bone integration or complex joint geometries.

- Practical benefit: You can mill prototypes and low-to-medium production runs of highly customized parts without expensive dedicated tooling.

- Superior Precision and Tight Tolerances Modern CNC mills routinely achieve tolerances of ±0.001 mm (±0.00004 inches) or better, with excellent repeatability across thousands of parts.

- How it’s achieved: Computer control eliminates human variability, and high-rigidity spindles + advanced feedback systems (linear encoders, thermal compensation) maintain accuracy even during long runs.

- Real example: Aerospace turbine blade prototypes or fuel system components require features like thin walls (0.5 mm) and precise airfoil curves—milling delivers this consistently.

- 2026 context: With AI-assisted toolpath optimization and vibration-dampening tech, tolerances are pushing toward sub-micron levels in high-end shops.

- Broad Material Compatibility CNC milling handles an extremely wide range of materials: soft plastics and aluminum, tough steels, titanium alloys, composites, brass, copper, and even some ceramics.

- Why it’s advantageous: The fixed workpiece and rotating tool provide better stability when cutting hard or brittle materials (less risk of deflection compared to turning long slender parts).

- Real example: In automotive prototyping, milling aluminum engine blocks or composite drone frames avoids distortion that might occur in other processes. Medical-grade stainless steel or PEEK implants are commonly milled for biocompatibility and precision.

- High Repeatability and Consistency Once programmed, the same G-code produces identical parts every time—critical for assemblies where interchangeability is required.

- Practical benefit: Reduces quality control time and scrap rates in production runs.

- Example: Electronics housings with multiple identical cavities or threaded inserts are milled in batches with near-zero variation.

- Excellent Surface Finishes and Detail Capability With small step-overs, ball-end mills, and high spindle speeds, milling can achieve Ra surface finishes as low as 0.4–0.8 µm without secondary polishing in many cases.

- Real example: Cosmetic parts (consumer electronics bezels) or optical components often come off the mill ready for anodizing or coating.

Milling shines brightest for prototypes, complex low-to-medium volume parts, and situations where geometric freedom is more important than raw speed.

Disadvantages of CNC Milling

- Slower Processing Time (Especially for Simple or High-Volume Parts) Milling often requires multiple tool changes, shallow passes (to avoid tool deflection), and careful roughing/finishing strategies.

- Why slower: Complex parts may need 10–30+ tool paths; each pass removes only a small amount of material.

- Comparison: A simple cylindrical shaft might take 10–20 minutes on a lathe but 45–90 minutes on a mill.

- Practical impact: Not ideal for very high-volume production of basic shapes—costs rise quickly beyond a few hundred units.

- Higher Tooling and Consumable Costs Frequent tool changes for different features (roughing end mills, finishing tools, ball mills, thread mills) lead to faster wear, especially on hard materials like stainless steel or titanium.

- Real numbers (2026 estimates): Tool costs can add $5–$30 per part in complex jobs; carbide inserts wear out after 20–200 parts depending on material.

- Example: Milling deep pockets in Inconel (aerospace superalloy) requires premium coated tools and frequent replacements.

- Significant Material Waste (Subtractive Nature) You start with a solid block and remove up to 70–90% of the material in roughing operations.

- High Initial Setup and Programming Costs Creating and verifying CAM toolpaths for complex parts takes skilled programmers and simulation time.

- Especially true for: 5-axis work, deep cavities, or thin-wall features that risk vibration or deflection.

- Practical drawback: One-off prototypes can be expensive unless you already have the program library.

- Limitations on Certain Geometries

- Deep cavities with small openings, very thin walls (<0.5 mm over long spans), or internal features without tool access remain challenging or impossible without special setups.

- Requires multi-axis machines or creative fixturing, which increases cost and lead time.

- Skill Dependency and Maintenance Needs While highly automated, CNC milling still requires experienced programmers, setup technicians, and regular maintenance (spindle bearings, way covers, coolant systems).

Quick Summary Table

| Aspect | Advantage Level | Key Benefit / Drawback |

| Geometric complexity | ★★★★★ | Best-in-class for 3D shapes, undercuts, multi-feature parts |

| Precision & tolerances | ★★★★★ | ±0.001 mm routine; excellent repeatability |

| Material range | ★★★★☆ | Very broad (metals, plastics, composites) |

| Speed for complex parts | ★★★☆☆ | Moderate to slow; many passes and tool changes |

| Cost for prototypes | ★★★★☆ | Excellent value for low-volume complex work |

| Cost for high-volume | ★★☆☆☆ | Higher due to time and tool wear |

| Material waste | ★★☆☆☆ | High (often 70%+ removed) |

| Setup/programming effort | ★★★☆☆ | Significant for new complex jobs |

When to Choose CNC Milling

Opt for CNC milling when your part has:

- Non-cylindrical / prismatic geometry

- Multiple faces, pockets, holes, threads, or 3D contours

- Tight tolerances on flat or contoured surfaces

- Prototype or low-to-medium production quantities

- Need for one-setup machining of complex features

If your project fits this description, milling often delivers the best balance of capability and quality—even if it takes longer or costs more per part than simpler processes.

If you’d like deeper examples for a specific industry (e.g., medical implants in Lahore’s growing manufacturing scene), cost breakdowns, or comparisons with other methods, just let me know!

Real-World Applications Across Industries

Turning dominates automotive (shafts, pulleys) and aerospace (turbine disks). Milling leads in medical (implants) and electronics (housings).

Case Study: Boeing uses 5-axis milling for fuselage parts, cutting time by 25% in 2025. In Lahore’s growing manufacturing scene, local shops use turning for custom bike parts.

How to Choose: A Comprehensive Guide

- Assess Shape: Round? Turning. Angular? Milling.

- Volume: High? Turning (economical). Low? Milling.

- Material: Ductile? Turning. Brittle? Milling.

- Budget/Time: Calculate ROI—turning often 20% cheaper.

- Test: Prototype both if hybrid viable.

Checklist:

- Symmetric? → Turning

- Multi-features? → Milling

- Tight deadline? → Evaluate speeds

Cost Breakdown and Comparison (2025-2026 Data)

Hourly rates: Turning $60-125; Milling $75-200. Machine costs: Entry-level turning $10k-30k; milling similar but 5-axis up to $100k.

Factors: Complexity adds 30-50%; volume discounts 40%. In 2026, global CNC market hits $93B, growing at 9.2% CAGR. Example: A shaft costs $15-25 in turning vs. $30-50 in milling.

Pro Tip: Batch runs cut costs—aim for 500+ units.

Common Mistakes to Avoid: 5 Critical Ones

- Wrong Tool Selection: Using milling for rounds wastes time.

- Ignoring Material Properties: High speeds on hard metals cause breakage.

- Skipping Maintenance: Leads to 20% downtime.

- Rushing Setup: Causes misalignment, scrapping parts.

- Over-Complex Designs: Adds unnecessary features, hiking costs.

Avoid by simulating in CAM and training operators—38% of overruns stem from poor choices.

Future Trends in 2026 and Beyond

AI optimizes paths, cutting waste 15%. Digital twins simulate full processes. Hybrids blend turning/milling with additive tech. Sustainability: Eco-coolants and recycled materials. 5-axis grows for aerospace. Market to $207B by 2035.

Key Takeaways

- Turning for speed on rounds; milling for versatility.

- Costs favor turning for volume.

- Applications span industries with hybrids rising.

- Avoid mistakes via planning.

- Trends: AI, sustainability drive growth.

- Market booming at 9.2% CAGR.

- Choose based on part needs for efficiency.

FAQs

1. What’s the main difference between CNC turning and CNC milling?

CNC turning uses a rotating workpiece and a stationary cutting tool to create cylindrical parts, while CNC milling uses a stationary workpiece and rotating tools to create complex shapes and surfaces. Milling is more versatile, while turning is faster for cylindrical designs.

2. Which process is better for high-volume production?

CNC turning is often better for high-volume production of cylindrical parts due to faster cycle times. However, CNC milling can be more efficient for parts with complex geometries that need multi-axis movements.

3. Can both CNC turning and milling be used for the same part?

Yes, hybrid approaches using both turning and milling in a single setup can be used for parts that require both cylindrical features and intricate surface details, improving efficiency and accuracy.

4. What’s the cost difference between CNC turning and milling?

CNC turning is generally more cost-effective for parts with simple, rotational shapes. CNC milling, while more expensive in terms of tooling and cycle time, is ideal for more complex designs with non-rotational features.

5. Which is more flexible for complex part geometries?

CNC milling is more flexible for complex, non-rotational geometries, such as pockets, slots, and 3D contours. CNC turning is better suited for parts with rotational symmetry, like shafts and rings.