What are Aerospace Grade Fasteners?

Aerospace grade fasteners are precision-manufactured joining components including bolts, screws, studs, pins, rivets, and specialty fasteners that meet stringent aerospace material and performance specifications. These critical elements are used throughout commercial aircraft structures, military jet assemblies, helicopter airframes, engine installations, landing gear systems, and spacecraft modules. Each aerospace fastener must provide reliable clamping force, resist fatigue crack initiation, withstand vibration environments, and maintain joint integrity through thousands of flight cycles. The quality of custom aerospace grade fasteners directly impacts structural safety, assembly reliability, and maintenance requirements across all aircraft systems, making material certification and dimensional accuracy non-negotiable.

Principales requisitos técnicos

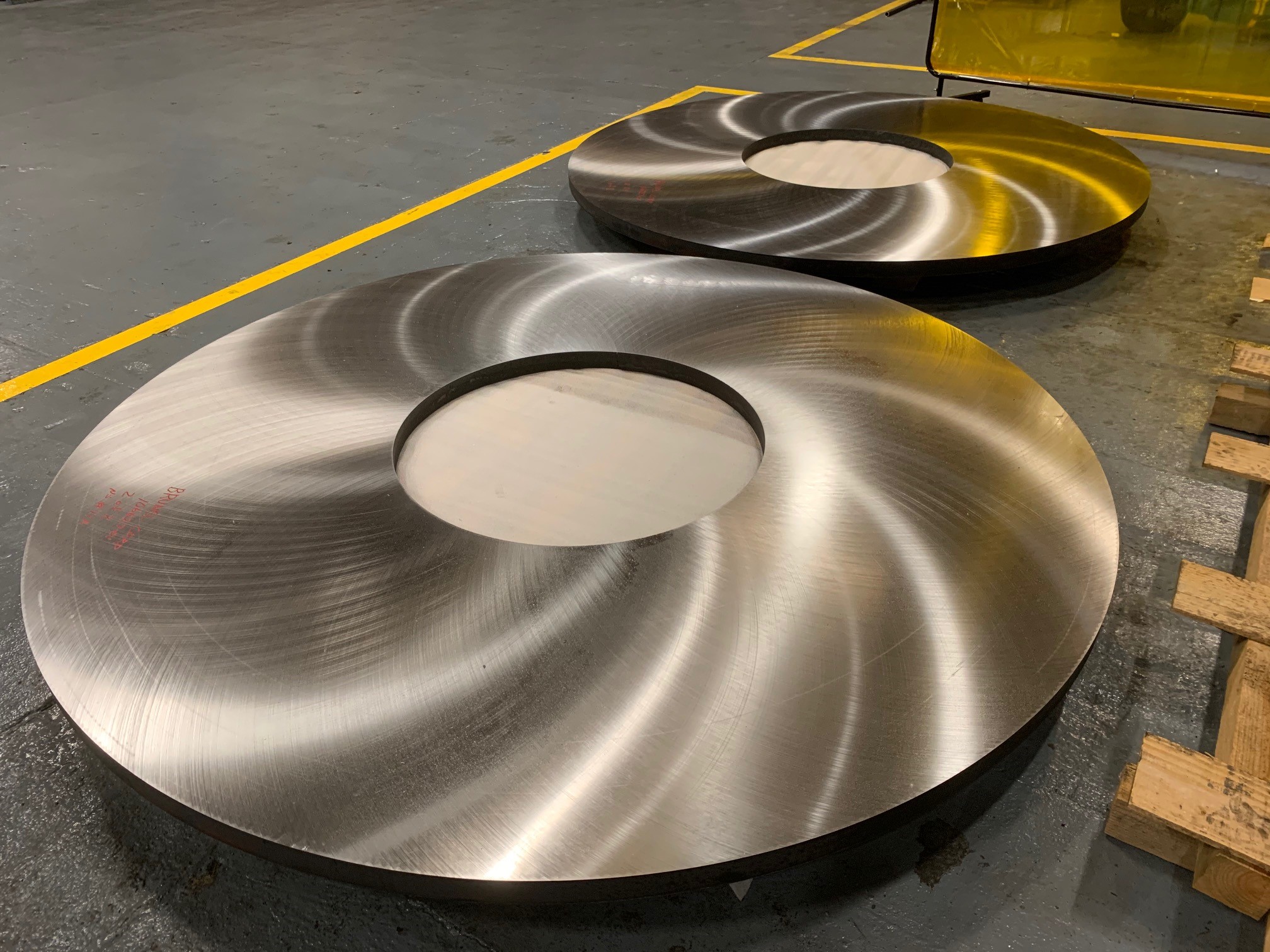

Manufacturing aerospace grade fasteners demands exceptional precision and strict material control. Typical tolerances range from ±0.005″ for head dimensions to ±0.001″ for thread pitch diameters, shank diameters, and grip length specifications that ensure proper fit and clamp load. Material specifications require Aleaciones aeroespaciales con certificación AMS including Ti-6Al-4V titanium (tensile strength 130 ksi, excellent corrosion resistance), 17-4PH stainless steel (condition H1150, 190 ksi), A286 high-temperature steel (service to 1,200°F), Inconel 718 for engine applications, and MP35N for extreme environments with complete mill certifications and heat lot traceability.

Surface finish requirements ensure proper assembly and corrosion protection. Thread surfaces require Class 2A or 3A tolerances per AS8879 specifications. Head underside surfaces typically demand Ra 63 micropulgadas for proper load distribution. Precision aerospace fasteners must withstand tensile loads from 1,000 to 200,000 PSI depending on size and grade, shear forces during flight maneuvers, vibration environments meeting MIL-STD-810 across 10-2000 Hz, and temperature cycling from -65°F to +600°F for hot-section applications. Components require controlled thread tolerances for torque-tension relationships, surface treatments meeting ASTM B117 salt spray resistance exceeding 1,000 hours, and magnetic particle inspection for critical applications to detect surface discontinuities.

Retos y soluciones de fabricación

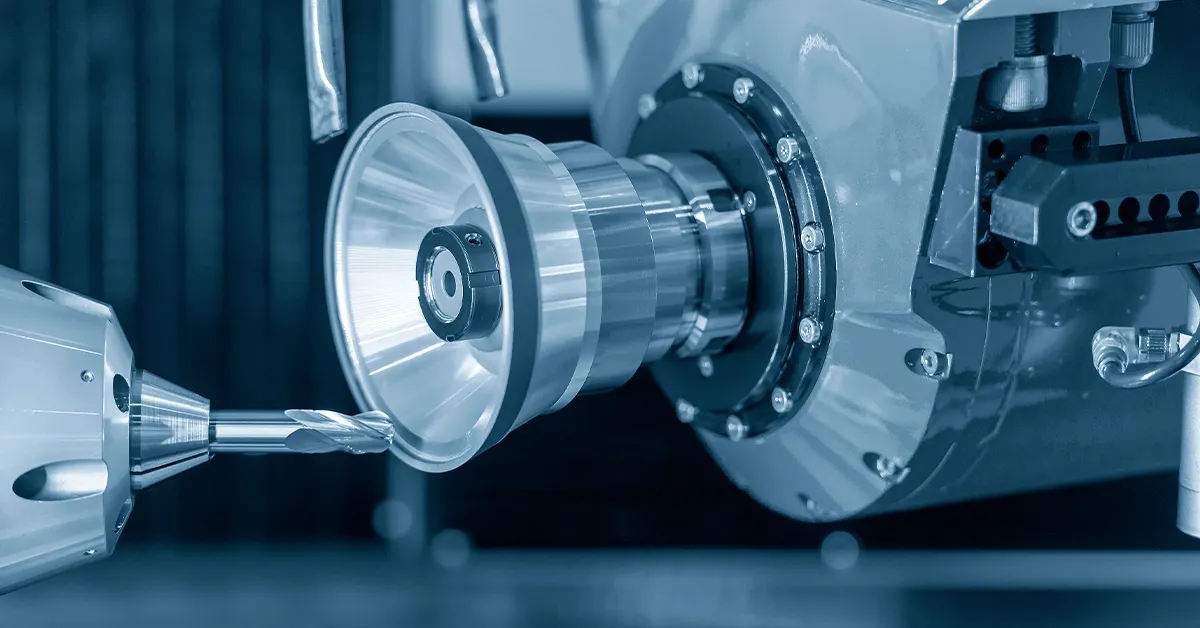

Machining aerospace grade fasteners presents unique technical challenges requiring specialized manufacturing capabilities. Complex geometries including precision threads, hex heads, specialized drive recesses (Hi-Lok, Torq-Set), and undercut features demand rigid tooling and process control. Small part sizes with tight tolerances require exceptional machine stability and tool wear monitoring. High-strength materials like A286 and Inconel exhibit work hardening and generate extreme cutting forces.

Yicen Precision overcomes these challenges through advanced manufacturing technology and process expertise. Our Swiss-type CNC turning centers enable complete fastener production including threading, heading, and drive recess machining in single operations, maintaining concentricity and thread quality. Thread rolling capabilities for larger fasteners produce superior fatigue strength compared to cut threads. We utilize herramientas de carburo y cerámica specifically designed for aerospace alloys, combined with optimized cutting parameters and high-pressure coolant delivery.

Quality control protocols ensure aerospace fasteners meet all specification requirements. Inspección del primer artículo verifies all dimensions including thread pitch diameter (using thread micrometers and comparators), head dimensions, and grip length. Thread gauging with GO/NO-GO gauges confirms Class 2A or 3A compliance. We perform tensile and shear testing on sample lots to verify mechanical properties. Every aerospace grade fastener lot receives comprehensive dimensional reports, material certifications, heat treatment records, and magnetic particle inspection reports for critical applications ensuring complete compliance with aerospace fastener specifications including NAS, MS, and AS standards.

Aplicaciones y casos prácticos

Precision-machined aerospace grade fasteners secure critical assemblies across diverse aerospace platforms:

- Airframe Structures: Fuselage skin attachment, wing spar bolts, bulkhead fasteners, and structural joint bolts for Boeing and Airbus commercial aircraft

- Aviones de combate militares: High-strength titanium fasteners, quick-release pins, and specialty fasteners for access panels on F-16, F-18, and stealth aircraft

- Instalación de motores: High-temperature fasteners, engine mount bolts, nacelle attachment hardware, and exhaust system fasteners for jet engines

- Conjuntos de tren de aterrizaje: High-strength bolts, clevis pins, retaining hardware, and structural fasteners for main and nose landing gear systems

- Helicopter Airframes: Vibration-resistant fasteners, rotor head bolts, transmission mounting hardware, and dynamic component attachment fasteners

- Spacecraft Systems: Titanium and Inconel fasteners for satellite structures, launch vehicle assemblies, and space station module connections

- Interior & Secondary Structures: Panel fasteners, seat track bolts, overhead bin hardware, and equipment mounting screws for cabin systems

Why Choose Yicen Precision for Aerospace Grade Fasteners?

Selecting the right manufacturing partner for aerospace grade fasteners CNC machining ensures assembly integrity and certification compliance. Yicen Precision brings specialized capabilities tailored to aerospace fastener requirements. Our servicios de prototipado rápido support new aircraft development programs, delivering first-article fastener samples within 7-10 days for fit-check validation and mechanical testing.

Proporcionamos escalabilidad de prototipo a producción, maintaining identical machining processes, heat treatment procedures, and quality protocols that eliminate costly re-qualification and reduce program timelines. Our engineering team delivers proactive Consulta DFM, identifying thread design optimization, material selection guidance, and surface treatment recommendations during the design phase. Every aerospace grade fastener batch includes trazabilidad completa de los materiales with certified mill test reports, heat lot numbers, heat treatment certifications, and dimensional inspection documentation satisfying AS9100D and NAS/MS specification requirements.

Our cost-effective approach leverages efficient Swiss-type machining, thread rolling capabilities, and strategic material procurement to deliver competitive pricing for both prototype quantities and production volumes. Yicen Precision understands that aerospace fasteners are critical to structural safety and assembly reliability. Contact us today for engineering consultation and a detailed quote on your aerospace grade fasteners manufacturing requirements.