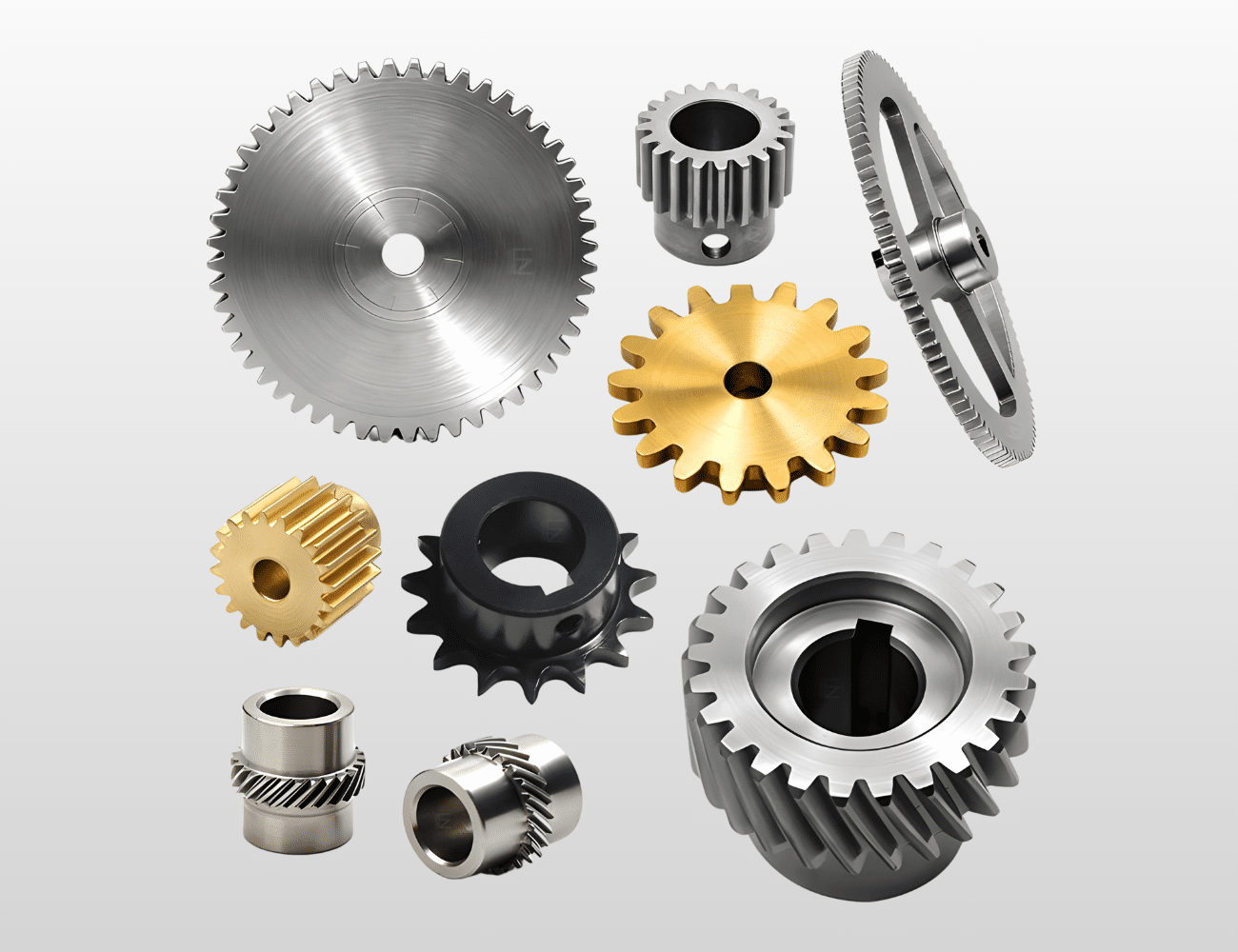

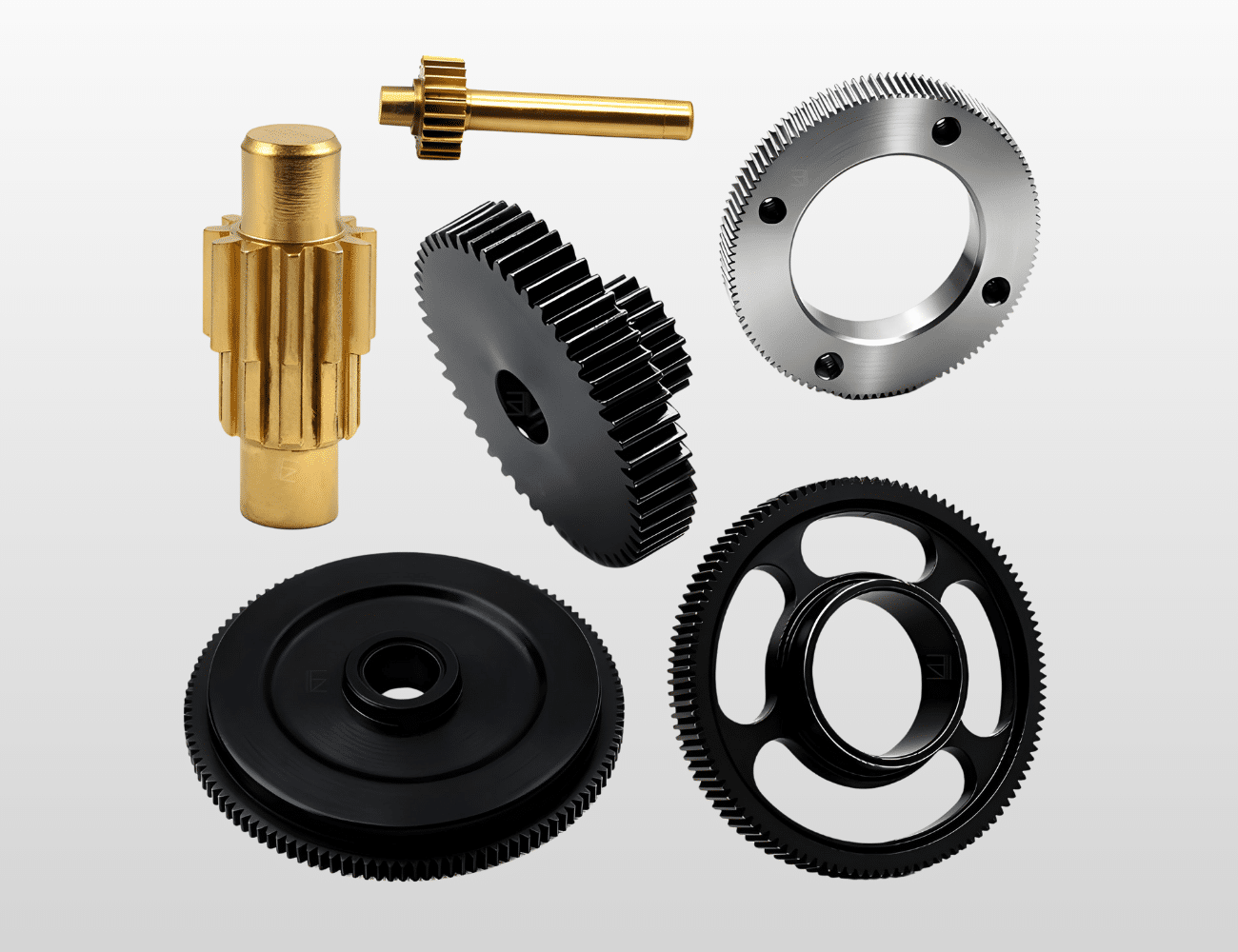

A. ¿Qué son las cajas de cambios y las piezas de transmisión?

Las cajas de cambios y las piezas de transmisión son componentes mecánicos diseñados con precisión que transmiten potencia rotacional y par motor entre diferentes secciones de sistemas de maquinaria industrial. Estos conjuntos incluyen carcasas de engranajes, ejes de transmisión, retenes de rodamientos, discos de embrague, soportes de engranajes planetarios y cajas de diferenciales. Son esenciales en maquinaria pesada, equipos de fabricación, maquinaria agrícola, vehículos de construcción y sistemas de producción automatizados. Su función principal es modificar las relaciones de velocidad, aumentar el par de salida, cambiar la dirección de rotación y distribuir la potencia de manera eficiente a través de múltiples ejes operativos, manteniendo la sincronización bajo una tensión mecánica extrema.

B. Principales requisitos técnicos

Las cajas de cambios de precisión y las piezas de transmisión exigen tolerancias excepcionalmente ajustadas, que suelen oscilar entre ±0,0005″ y ±0,001″ para superficies de acoplamiento críticas e interfaces de montaje de engranajes. Las especificaciones de los materiales requieren aleaciones de alta resistencia, como acero 4140, acero inoxidable 17-4 PH, aluminio 7075 y aleaciones de bronce con índices de dureza específicos (HRC 28-62 en función de la aplicación). Los requisitos de acabado superficial varían de 32 Ra para exteriores de carcasas a 8-16 Ra para asientos de rodamientos de precisión y superficies de sellado.

Estos componentes deben soportar cargas cíclicas continuas, fuerzas de impacto y vibraciones sin sufrir deformaciones ni fallos por fatiga. Las zonas de concentración de tensiones requieren radios de redondeo cuidadosos y optimización geométrica. La resistencia a la temperatura es crítica, con rangos de funcionamiento de -40°F a 400°F dependiendo de la aplicación. Las consideraciones medioambientales incluyen la resistencia a fluidos hidráulicos, lubricantes, humedad y contaminantes, al tiempo que se mantiene la estabilidad dimensional durante todo el ciclo de vida operativo.

C. Retos y soluciones de fabricación

El mecanizado de cajas de cambios y piezas de transmisión presenta retos importantes, como cavidades internas complejas, cavidades profundas con acceso limitado a la herramienta y mantenimiento de la concentricidad en múltiples orificios de cojinetes. Los materiales endurecidos provocan un desgaste excesivo de la herramienta y requieren estrategias de corte especializadas. Las secciones de paredes finas son propensas a desviarse durante el mecanizado, lo que provoca imprecisiones dimensionales. Los componentes tratados térmicamente pueden sufrir distorsiones que requieren operaciones de rectificado de precisión posteriores al endurecimiento.

Yicen Precision supera estos retos mediante un avanzado mecanizado CNC de 5 ejes que proporciona acceso simultáneo a múltiples caras y ángulos de herramienta óptimos para trabajos en cavidades profundas. Utilizamos software CAM con estrategias de trayectorias de herramienta adaptables que minimizan las fuerzas de corte en paredes finas a la vez que mantienen tasas agresivas de eliminación de material en secciones gruesas. Nuestros protocolos de inspección de precisión incluyen verificación CMM de dimensiones críticas, análisis de acabado superficial y pruebas de dureza en múltiples ubicaciones.

Para conjuntos de transmisión complejos, empleamos sistemas de suministro de refrigerante a alta presión y herramientas de carburo con revestimientos especializados para prolongar la vida útil de las herramientas al mecanizar aceros endurecidos. La verificación dimensional se realiza en varias fases de producción mediante calibrado en proceso e informes finales de MMC con documentación de trazabilidad completa.

D. Aplicaciones y casos de uso

Los reductores y piezas de transmisión para maquinaria industrial fabricados por Yicen Precision sirven para diversas aplicaciones:

- Equipos de fabricación pesada - Máquinas CNC, prensas y sistemas de montaje automatizados

- Maquinaria agrícola - Accionamientos de tractores, cosechadoras y sistemas de riego

- Equipos de construcción - Excavadoras, bulldozers y sistemas de manipulación de materiales

- Maquinaria minera - Cadenas cinemáticas de trituradoras, cintas transportadoras y equipos de perforación

- Sistemas de manipulación de materiales - Grúas, polipastos y robótica para almacenes automatizados

- Robótica industrial - Actuadores de precisión y sistemas de posicionamiento multieje

- Equipos de generación de energía - Turbinas eólicas, sistemas hidroeléctricos y grupos electrógenos

- Equipos marinos y de alta mar - Cabrestantes, sistemas de propulsión y maquinaria de cubierta

E. ¿Por qué elegir Yicen Precision para cajas de cambios y piezas de transmisión?

Yicen Precision ofrece una experiencia inigualable en la fabricación de cajas de engranajes y piezas de transmisión complejas con precisión dimensional e integridad de los materiales garantizadas. Nuestra rápida capacidad de respuesta permite tanto el desarrollo de prototipos como la producción de grandes volúmenes sin sacrificar los estándares de calidad. Proporcionamos un amplio soporte de ingeniería que incluye la consulta DFM para optimizar los diseños para la fabricación, la reducción de costes y la mejora del rendimiento.

Nuestros sistemas de trazabilidad de materiales garantizan una documentación completa, desde la certificación de materias primas hasta los informes de inspección final, cumpliendo las normas industriales más estrictas. Mantenemos alianzas estratégicas de inventario que permiten un abastecimiento rentable de materiales tanto para aleaciones estándar como exóticas. Nuestra capacidad de producción escalable da cabida a pedidos desde prototipos individuales hasta miles de unidades de producción con una calidad constante en todos los lotes. Con décadas de experiencia en la fabricación de cajas de engranajes, comprendemos la naturaleza crítica de los componentes de transmisión de potencia y ofrecemos soluciones que superan las expectativas.

Póngase en contacto con nosotros hoy mismo para obtener un presupuesto personalizado de su proyecto de mecanizado CNC de cajas de cambios y piezas de transmisión.