What are Conveyors and Actuators?

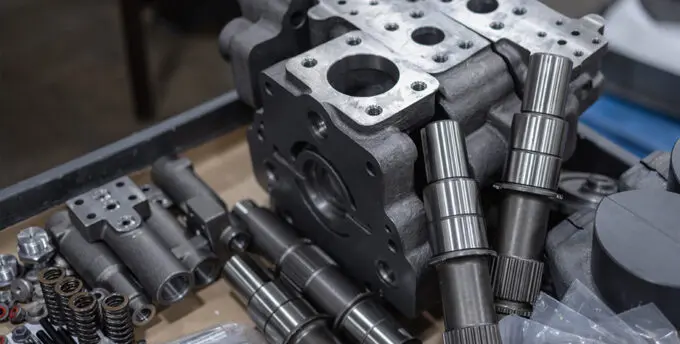

Conveyors and actuators are essential mechanical systems that move materials and control equipment positioning in automated facilities. These components include conveyor roller shafts, sprockets, drive pulleys, idler brackets, actuator cylinders, mounting blocks, transfer plates, and positioning mechanisms used throughout manufacturing plants, distribution centers, packaging lines, and automated warehouses. Each component must provide reliable motion control, withstand repetitive loading, support material weight, and integrate seamlessly with motors and controls. The quality of precision conveyors and actuators directly impacts production throughput, system uptime, and operational efficiency across all material handling applications.

Key Technical Requirements

Manufacturing conveyors and actuators demands robust precision engineering. Typical tolerances range from ±0.010″ for structural components to ±0.002″ for bearing surfaces, shaft diameters, and mounting interfaces that ensure proper alignment and smooth operation. Material specifications include steel grades (1018, 1045, 4140) for shafts and structural parts, aluminum alloys (6061-T6) for lightweight components, stainless steel (304, 316) for food processing and clean environments, and cast iron for heavy-duty frames and housings.

Surface finish requirements balance functionality with cost. Bearing surfaces need Ra 63 microinches for proper roller and bearing fit. Conveyor rollers require Ra 125 microinches for material contact surfaces. Conveyor and actuator components must handle loads from 50 to 5,000+ pounds depending on application, continuous duty cycles, impact loading from material transfer, and temperature ranges from -20°F to 200°F in typical industrial settings. Components require proper shaft straightness within 0.005″ per foot, bore concentricity for bearing installation, corrosion resistance for longevity, and proper surface treatments for wear resistance in high-cycle applications.

Manufacturing Challenges & Solutions

Machining conveyors and actuators presents practical manufacturing challenges. Large component sizes and heavy materials require substantial machine capacity and rigid setups. High production volumes demand efficient processes and quick changeovers. Maintaining consistent quality across batches while meeting cost targets requires process optimization. Various shaft lengths and diameters need flexible fixturing solutions.

Yicen Precision overcomes these challenges with proven production strategies. Our CNC turning centers with bar feeders efficiently produce conveyor shafts, rollers, and actuator rods in volume with consistent quality. 5-axis machining centers handle complex mounting brackets, transfer plates, and actuator housings with multiple features in single setups. We use quick-change tooling systems and standardized work holding for fast setup times and reduced cycle times.

Quality control ensures conveyor and actuator components meet all operational requirements. In-process inspection monitors critical dimensions during production runs to catch variations early. CMM verification confirms bearing fits, mounting hole patterns, and geometric relationships. We perform straightness measurement on shafts and rods using precision V-blocks and indicators. Every component receives dimensional verification, material certifications, and quality documentation ensuring complete compliance with material handling system requirements and ISO quality standards.

Applications & Use Cases

Precision-machined conveyors and actuators serve essential functions across diverse automation applications:

- Distribution Centers: Conveyor rollers, drive shafts, transfer mechanisms, and sorting actuators for warehouse automation and package handling

- Manufacturing Assembly Lines: Product transfer conveyors, pneumatic actuator components, and positioning systems for automotive and electronics production

- Food and Beverage Processing: Stainless steel conveyor components, sanitary actuator housings, and material handling parts for food safety compliance

- Packaging Systems: High-speed conveyor rollers, product diverters, pusher actuators, and case handling components for packaging automation

- Airport Baggage Handling: Heavy-duty conveyor components, sorting mechanisms, and transfer actuators for baggage systems

- Pharmaceutical Manufacturing: Clean-compatible conveyor parts and precision actuators for pharmaceutical production and packaging

- E-commerce Fulfillment: Sortation system components, conveyor network parts, and automated storage actuators for order fulfillment centers

Why Choose Yicen Precision for Conveyors and Actuators?

Yicen Precision specializes in conveyors actuators CNC machining with lead times as short as 1-2 weeks for standard components and 2-3 weeks for custom designs. Our scalable manufacturing supports both small orders for maintenance and replacement parts (10-25 units) and production quantities of 100 to 1,000+ units for system builders and integrators.

We provide comprehensive engineering support including DFM consultation to optimize designs for production efficiency, material selection guidance for specific environments, and cost reduction recommendations through design modifications. Our quality documentation includes inspection reports, material certifications, and traceability records supporting ISO 9001 compliance and customer requirements.

Our cost-effective approach leverages efficient production machining, volume pricing on materials, and optimized processes to deliver competitive pricing without sacrificing quality. We understand conveyor and actuator components need reliability that keeps production lines running. Whether you’re building new automation systems, upgrading existing conveyors, or need replacement components for maintenance, our expertise ensures your parts deliver the durability and performance your operations demand. Contact us today for technical consultation and volume quotes on your conveyors and actuators manufacturing requirements.