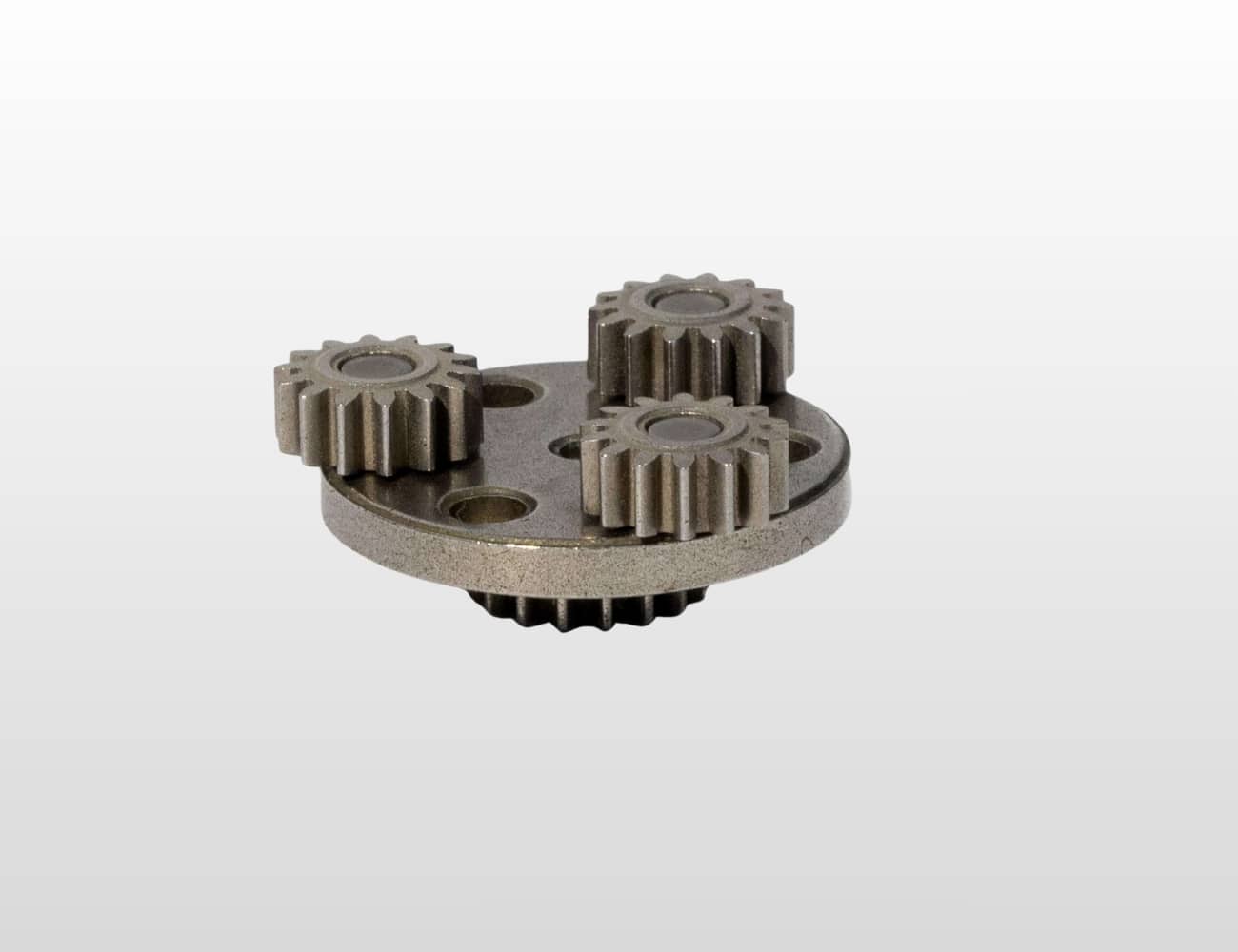

What are Precision Gears?

Precision gears are precisely manufactured mechanical components with accurately formed teeth that mesh together to transmit rotational motion and torque between shafts. These essential parts include spur gears, helical gears, bevel gears, worm gears, rack and pinion sets, and planetary gear components used throughout industrial robots, servo systems, CNC machines, automated assembly equipment, and material handling systems. Each gear must maintain accurate tooth profile, proper pitch diameter, correct spacing, and smooth surface finish to ensure efficient power transmission, minimal noise, and long operational life. The quality of custom precision gears directly impacts system efficiency, positioning accuracy, and mechanical reliability across all automation applications.

Key Technical Requirements

Manufacturing precision gears demands exacting dimensional control and process expertise. Typical tolerances range from ±0.005″ for gear blank dimensions to ±0.0005″ for tooth spacing, profile accuracy, and lead variations that ensure smooth meshing and proper load distribution. Material specifications include steel grades (4140, 4340, 8620) for high-strength gears requiring heat treatment, stainless steel (303, 304, 17-4PH) for corrosive environments, bronze alloys (C932, C954) for worm gear applications, and aluminum alloys (7075-T6) for lightweight high-speed gears.

Surface finish requirements are critical for gear performance. Tooth flanks need Ra 32 microinches or smoother for quiet operation and minimal wear. Ground gears may require Ra 16 microinches for precision applications. Precision gears must meet AGMA Quality Classes 7-10 depending on application, with Class 8-9 being common for automation systems. Components must handle torque loads from 1 to 1,000+ lb-ft, operating speeds from 100 to 10,000 RPM, proper tooth contact patterns across the face width, and temperature stability during operation. Requirements include accurate pitch diameter within 0.001″, proper tooth profile per involute standards, controlled backlash (typically 0.002″ to 0.008″), and appropriate heat treatment for surface hardness (typically 58-62 HRC for case-hardened gears).

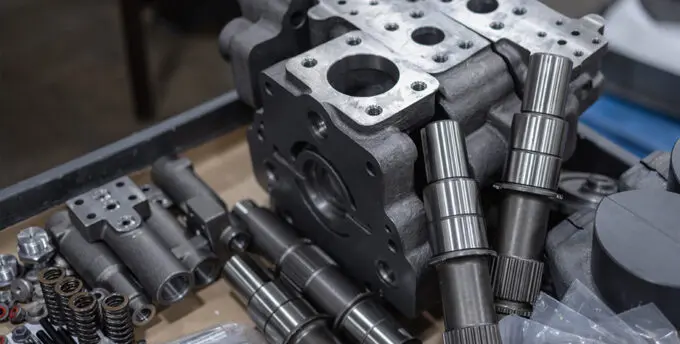

Manufacturing Challenges & Solutions

Machining precision gears presents specialized technical challenges. Achieving accurate involute tooth profiles requires specialized equipment and tooling. Maintaining consistent tooth spacing around the entire circumference demands precise indexing. Hard materials and heat-treated blanks create tool wear and dimensional changes. Minimizing distortion during heat treatment while maintaining tight tolerances requires careful process control.

Yicen Precision overcomes these challenges with specialized gear manufacturing capabilities. Our CNC gear hobbing machines produce accurate involute tooth profiles with consistent spacing and proper lead angles for both spur and helical gears. 5-axis CNC milling with gear cutting software enables production of bevel gears and custom tooth profiles. We use precision grinding for finishing hardened gears to final tolerances and surface finish requirements.

Quality control ensures precision gears meet all functional requirements. Gear inspection equipment measures tooth profile, lead, pitch, and runout using specialized gear analyzers or CMM with gear software. Rolling gear testers verify smooth meshing and proper tooth contact patterns. We perform backlash measurement using precision pins and indicators. Every precision gear receives dimensional reports, gear quality analysis, material certifications, and heat treatment documentation ensuring complete compliance with power transmission requirements and ISO quality standards.

Applications & Use Cases

Precision-machined gears serve essential power transmission functions across diverse automation applications:

- Industrial Robotics: High-precision gears for robot joint actuators, harmonic drives, and planetary gearboxes requiring accurate positioning

- CNC Machine Tools: Spindle drive gears, feed mechanism gears, and tool changer components for machining centers and lathes

- Servo Motor Systems: Precision reduction gears, encoder gears, and coupling gears for high-accuracy positioning systems

- Automated Assembly Equipment: Timing gears, index drive components, and transfer mechanism gears for synchronized operations

- Packaging Machinery: High-speed gears for filling equipment, labeling machines, and cartoning systems requiring precise timing

- Material Handling Systems: Conveyor drive gears, elevator mechanisms, and sortation system gears for warehouse automation

- Medical Device Automation: Precision miniature gears for surgical robots, diagnostic equipment, and pharmaceutical manufacturing systems

Why Choose Yicen Precision for Precision Gears?

Yicen Precision specializes in precision gears CNC machining with lead times as short as 2-3 weeks for standard gears and 3-4 weeks for complex designs requiring grinding or special heat treatment. Our flexible manufacturing supports both prototype development for new drive systems (5-10 units) and production quantities from 50 to 1,000+ units for equipment manufacturers and system builders.

We provide comprehensive engineering support including DFM consultation to optimize gear designs for manufacturability and performance, material selection guidance for specific load and speed requirements, and heat treatment recommendations for desired hardness and wear resistance. Our quality documentation includes detailed gear inspection reports, tooth contact pattern analysis, material certifications, and heat treatment records supporting ISO 9001 compliance.

Our cost-effective approach leverages efficient gear cutting processes, in-house heat treatment coordination, and strategic material sourcing to deliver competitive pricing. We understand precision gears require accuracy that directly impacts system performance and reliability. Whether you’re building servo-driven robots, high-speed packaging equipment, or precision machine tools, our expertise ensures your gears deliver the smoothness and durability your applications demand. Contact us today for technical consultation and rapid quotes on your precision gears manufacturing requirements.