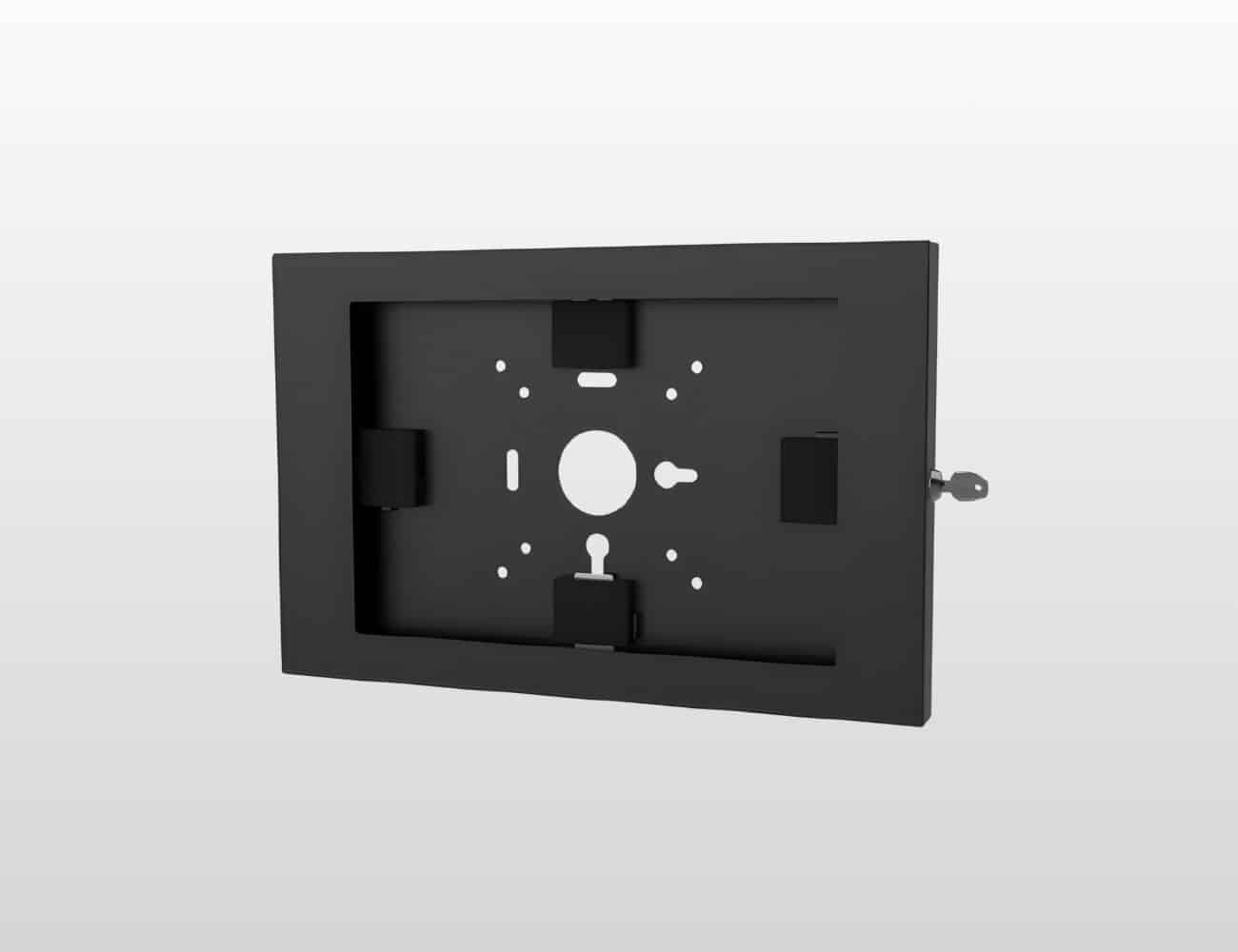

A. What are Smartphone and Tablet Enclosures?

Smartphone and tablet enclosures are precision-engineered structural housings that form the outer shell and internal framework of mobile computing devices. These sophisticated components include smartphone mid-frames with integrated antenna bands and mounting provisions, rear cover panels with camera module cutouts and wireless charging coils, tablet unibody housings with display bezels and port assemblies, side frame assemblies with precision button cutouts and speaker grilles, SIM card tray housings, camera bezel rings with lens protection, and protective battery covers. They are critical in flagship smartphones, budget mobile devices, professional tablets, consumer iPads, rugged enterprise handhelds, gaming phones, and foldable devices.

The primary functions of smartphone and tablet enclosures include providing rigid structural support for displays, batteries, and circuit boards within minimal thickness constraints, protecting sensitive electronics from drops, moisture, and environmental hazards, integrating antenna structures for cellular, WiFi, Bluetooth, and NFC connectivity without signal degradation, enabling precise alignment of multiple cameras, sensors, and biometric readers, facilitating wireless charging through non-metallic rear panels or precision-machined charging zones, dissipating heat from processors and charging circuits, and delivering premium aesthetics with flawless surface finishes that define brand identity and product positioning. Their design directly impacts device durability, signal performance, thermal management, user ergonomics, and perceived value in intensely competitive mobile markets.

B. Key Technical Requirements

Manufacturing smartphone and tablet enclosures demands extreme precision across mechanical, electrical, and aesthetic dimensions. Dimensional tolerances for display fitment surfaces typically range from ±0.003″ to ±0.005″ to ensure uniform gap spacing around screens, proper touch digitizer alignment, and consistent bezel appearance. Camera lens cutout positioning must maintain tolerances of ±0.002″ for optical axis alignment preventing image quality degradation or vignetting.

Material specifications balance strength, weight, RF transparency, and thermal properties. Aluminum alloys provide excellent rigidity at minimal weight with wall thicknesses down to 0.040″ for ultra-thin flagship devices. Magnesium alloys enable even lighter construction at 0.050″ walls for large tablets. Surface finish requirements are exceptionally stringent—external decorative surfaces demand Ra values below 16 microinches for mirror-like appearance suitable for premium anodizing, while internal surfaces may specify Ra 32-63 microinches focused on functionality.

Antenna slot machining requires precise width control within ±0.001″ and depth accuracy within ±0.002″ to maintain target impedance and resonant frequency for wireless performance. Plastic injection inserts for antenna isolation must fit with minimal gaps, typically within 0.002″ tolerance. Button cutout positioning requires ±0.003″ accuracy to ensure proper tactile feedback and switch alignment through thousands of activation cycles.

Thread specifications for miniature fasteners demand exceptional precision with M1.4 to M2.0 threads requiring pitch accuracy within ±0.0005″ and minor diameter control within ±0.001″. Surface flatness for adhesive bonding of displays and rear panels requires tolerances within 0.002″ to prevent air gaps affecting optical clarity or water resistance. Corner radii must maintain consistency within ±0.005″ for ergonomic comfort and aesthetic uniformity.

Thermal management features include precision-machined channels for heat pipes, graphite thermal pad recesses with depth control within ±0.003″, and internal ribbing for structural reinforcement without compromising thinness. Port cutouts for USB-C, Lightning, and audio jacks require positional accuracy within ±0.003″ and perpendicularity within 0.002″ for reliable connector insertion through repeated use cycles. Water resistance specifications for IP67/IP68 ratings demand sealing surfaces with flatness within 0.001″ and surface finish below 32 microinches.

C. Manufacturing Challenges & Solutions

Machining smartphone and tablet enclosures presents extraordinary challenges including achieving micron-level tolerances on thin-walled structures highly susceptible to deflection, producing hundreds of precision features including camera cutouts, button holes, speaker grilles, and antenna slots on compact surfaces, maintaining dimensional stability in materials prone to warping, creating flawless cosmetic surfaces free from any visible imperfections, and integrating complex internal geometries for component mounting within severe space constraints. Aluminum’s tendency to produce built-up edge affects surface finish. The compact size amplifies the visual impact of any machining defect or dimensional variation.

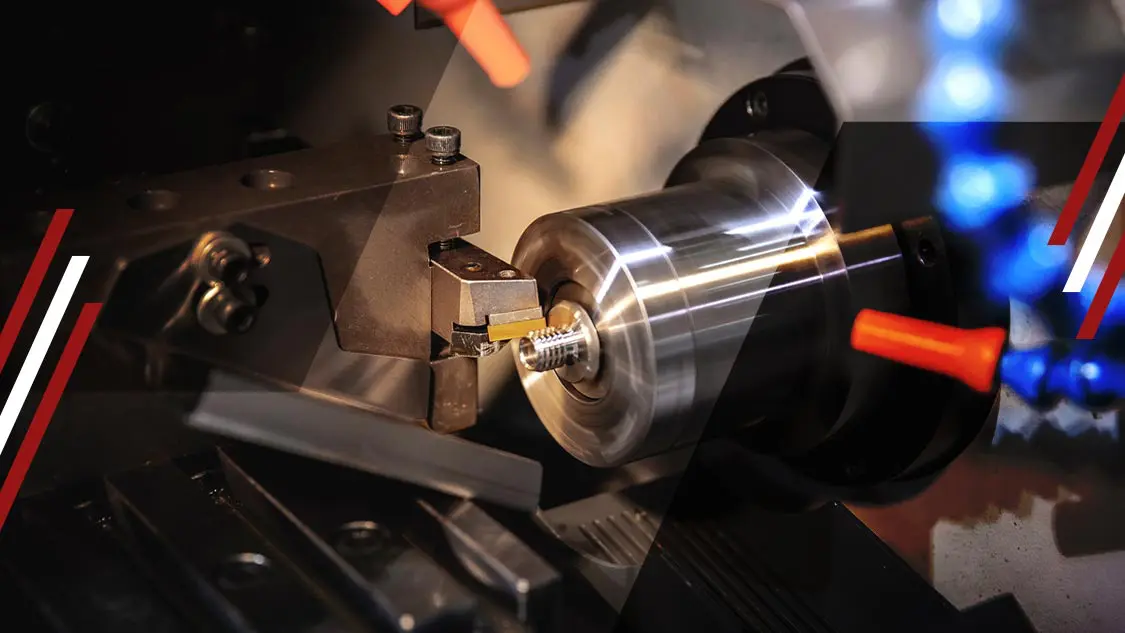

Yicen Precision addresses these challenges through advanced micro-machining capabilities and process control specifically developed for mobile device enclosures. Our high-precision 5-axis CNC machining centers equipped with spindles capable of 40,000+ RPM and advanced tool holders minimize runout below 0.0002″, enabling extremely fine surface finishes and tight tolerances. Specialized micro-tooling down to 0.010″ diameter enables precise machining of speaker grille arrays, antenna slots, and miniature fastener holes.

Custom vacuum and magnetic workholding fixtures designed specifically for smartphone and tablet geometries support thin-walled enclosures during machining without inducing stress or leaving clamping marks on finished surfaces. Multi-operation fixtures enable complete machining of all surfaces with minimal repositioning, maintaining geometric relationships critical for assembly. High-speed machining strategies with optimized cutting parameters reduce cutting forces to prevent deflection while maintaining productivity.

Climate-controlled manufacturing environments maintain temperature stability within ±1°F and humidity control preventing thermal expansion and material dimensional changes during precision operations. Advanced CAM programming incorporates rest machining strategies that progressively refine surfaces to final dimensions, compensating for tool deflection and wear. Automated in-process measurement using touch probes verifies critical dimensions during machining, enabling real-time adjustments before features are completed.

Surface finishing employs diamond tooling for mirror finishes directly from machining, eliminating secondary grinding operations. Progressive cutting strategies with multiple finishing passes at decreasing depths produce Ra values below 16 microinches. Deburring protocols utilize precision brushing, tumbling, and hand finishing techniques that remove sharp edges without affecting critical dimensions or surface quality.

Quality control includes comprehensive CMM inspection of all critical dimensions using optical probing for delicate features, automated optical inspection systems scanning 100% of surfaces for cosmetic defects including scratches, dents, tool marks, and discoloration, laser scanning for overall dimensional verification and contour accuracy, and functional assembly testing with actual displays, cameras, and circuit boards validating fitment. Antenna slot dimensions undergo specialized RF measurement ensuring electrical performance meets specifications. Statistical process control monitors key parameters across production ensuring consistency batch to batch.

D. Applications & Use Cases

Precision-machined smartphone and tablet enclosures enable exceptional mobile devices across diverse consumer electronics applications:

- Flagship Smartphones: Premium aluminum or titanium frames with precision camera arrays, integrated antenna bands, ceramic or glass rear panels, and flawless anodized finishes for high-end mobile devices

- Mid-Range Mobile Devices: Cost-optimized aluminum or reinforced plastic enclosures with essential features, reliable construction, and attractive finishes for mainstream smartphone markets

- Professional Tablets: Large-format aluminum unibody housings with precision Apple Pencil charging channels, Smart Connector cutouts, and camera module integration for creative professionals

- Rugged Enterprise Devices: Reinforced enclosures with enhanced corner protection, sealed port covers, and durable finishes meeting MIL-STD-810G specifications for field operations

- Gaming Smartphones: Specialized housings with aggressive styling, cooling system integration, shoulder button assemblies, and RGB lighting features for mobile gaming enthusiasts

- Foldable Devices: Complex hinge mechanisms, ultra-thin flexible section housings, and precision multi-panel assemblies enabling innovative form factors

- Budget Tablets and E-Readers: Lightweight plastic or basic aluminum enclosures optimized for cost-effectiveness while maintaining quality appearance for education and entertainment markets

E. Why Choose Yicen Precision for Smartphone and Tablet Enclosures?

Yicen Precision delivers world-class expertise in smartphone and tablet enclosures CNC machining through our specialized micro-manufacturing capabilities and comprehensive understanding of mobile device requirements. Our rapid prototyping services provide functional enclosure samples within 5-7 days, enabling industrial design validation, assembly testing, antenna performance verification, and drop testing before committing to mass production tooling and finishing processes.

We offer flexible scalability from innovative startup designs requiring hundreds of units for market testing through established brands demanding millions of enclosures monthly for global distribution, maintaining micron-level precision and flawless aesthetics regardless of production volume. Our engineering team provides expert DFM consultation specifically focused on mobile device enclosures, including recommendations for antenna integration optimization, camera module alignment, manufacturing tolerance allocation, cost reduction opportunities, and design refinements that enhance manufacturability while preserving industrial design intent.

Complete material traceability with certified mill test reports ensures specifications are met and documented supporting regulatory compliance including FCC, CE, and carrier certifications for mobile devices. Our cost-effective solutions leverage efficient machining strategies, advanced automation reducing labor costs, optimized material utilization through precision nesting, and process refinement that deliver superior smartphone and tablet enclosures at competitive pricing enabling attractive product positioning without compromising quality, precision, or premium appearance.

With dedicated project management providing single-point contact throughout development and production, transparent communication with real-time production updates, commitment to aggressive delivery schedules supporting consumer product launch windows, and comprehensive quality documentation with full inspection reports, we become your trusted manufacturing partner for bringing innovative mobile devices to market that consumers love and rely on daily.